2545, 308-531, 3235, 800-705, 800-704 specifications

Graco Inc. is a leading manufacturer in the field of fluid handling equipment, renowned for its innovation and commitment to quality. Among its extensive product line, Graco offers a variety of models including the 800-703, 800-701, 800-702, 308-531, and 800-705. Each of these models is designed to meet specific needs in different industrial applications, ensuring efficiency and reliability in operations.The Graco 800-703 is optimized for high-capacity pumping applications. This model features robust construction materials that enhance durability, making it ideal for handling various industrial fluids. Its advanced motor technology ensures consistent performance, while the easy-to-use controls provide operators with the precision they need for optimal results.

In contrast, the 800-701 model is particularly well-suited for low-pressure applications. It boasts a lightweight design, making it easy to transport and operate in confined spaces. The 800-701 utilizes a unique diaphragm technology that minimizes wear and tear, ensuring longevity and reduced maintenance costs. Its design also includes noise-reduction features, making it perfect for environments where sound levels need to be kept to a minimum.

The Graco 800-702 is a versatile option that excels in both medium-pressure environments and lightweight applications. This model is equipped with a user-friendly digital display, which allows operators to monitor fluid flow and pressure in real-time. It features an innovative air motor design that enhances efficiency while minimizing operational costs.

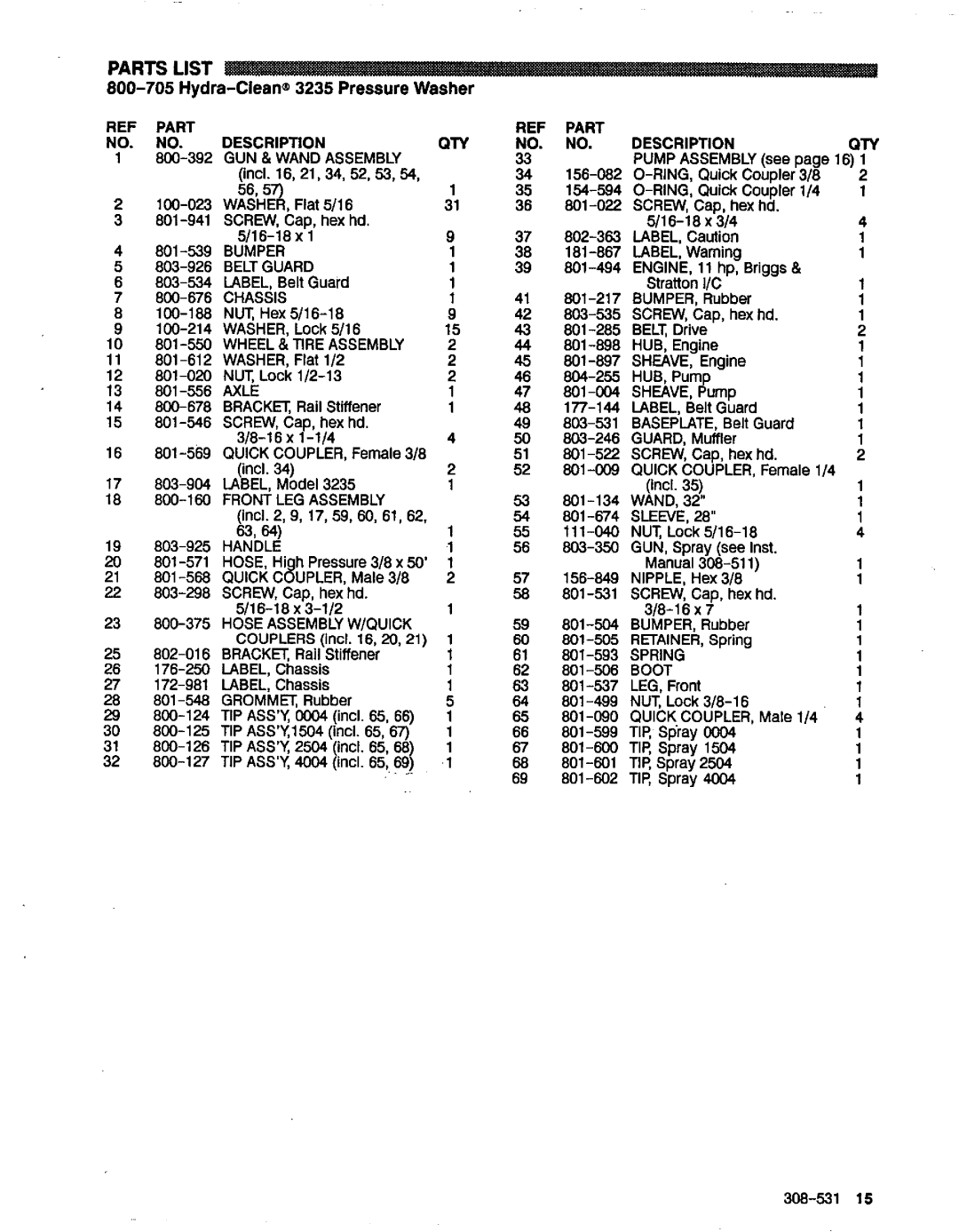

The Graco 308-531 is built for heavy-duty applications and offers exceptional pressure resistance. Its robust construction allows it to handle viscous materials with ease, making it a favorite in industries like construction and automotive. The 308-531 also incorporates the latest safety features, including automatic shut-offs and pressure relief valves, to protect both the equipment and operators.

Finally, the Graco 800-705 combines portability with performance. Its compact size does not compromise on power, as it can efficiently handle a wide range of fluids. This model is particularly popular in paint spraying applications, thanks to its excellent atomization technology, which guarantees a smooth and uniform finish.

In summary, Graco Inc. continues to lead the way in fluid handling solutions with models like the 800-703, 800-701, 800-702, 308-531, and 800-705. Each model features unique technologies and specifications tailored to specific industrial needs, reinforcing Graco’s reputation for reliability and innovation.