DISPLACEMENT PUMP

*212

214

TORQUE NUT TO 3±4

223(0.34±0.35 N.m)

201

221

Fig 19±2

![]() 203*

203*

APPLY ONE DROP

OF SEALANT TO

THESE THREADS

NOTE AND MAINTAIN THIS ALIGNMENT THROUGHOUT STEPS 2, 3 and 4

224

0082

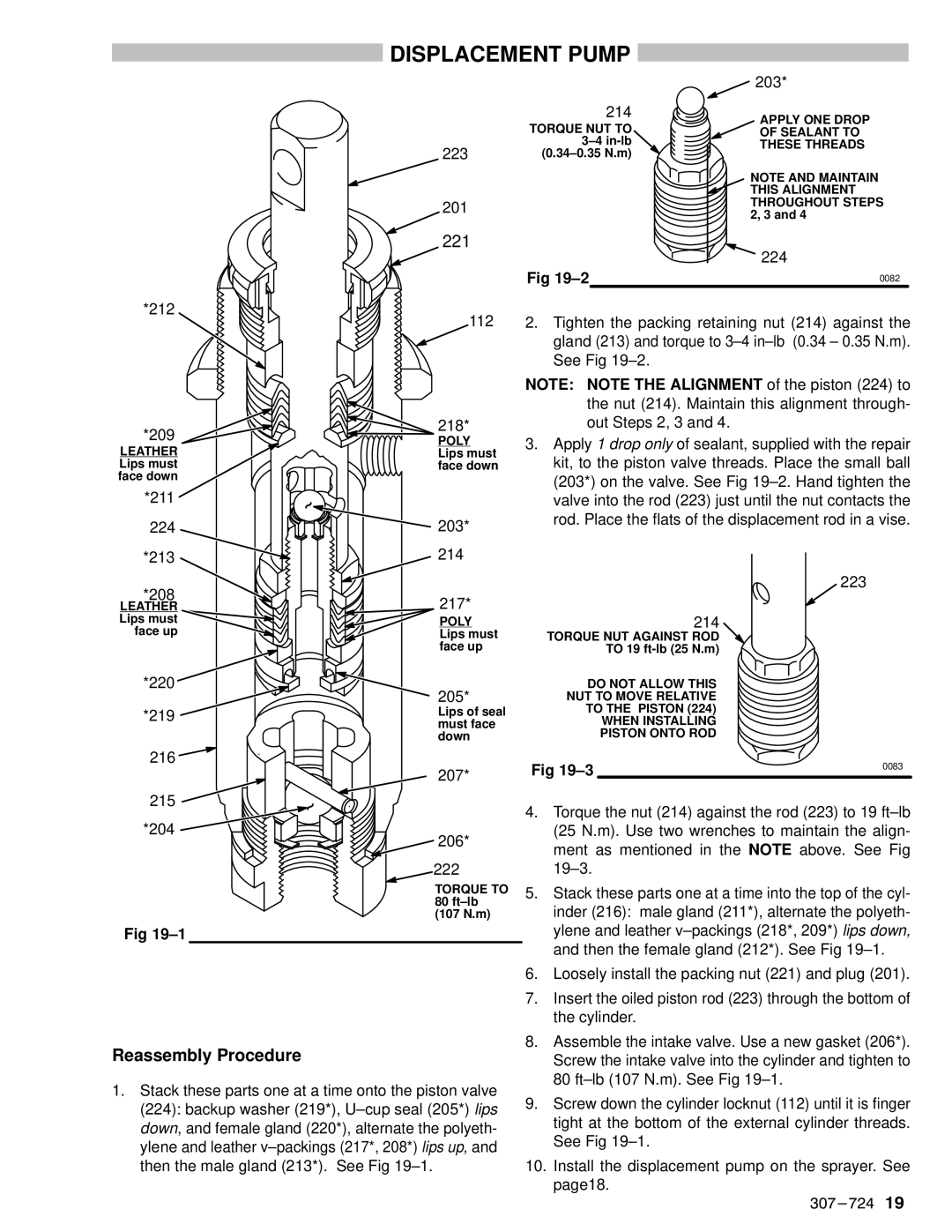

1122. Tighten the packing retaining nut (214) against the gland (213) and torque to 3±4 in±lb (0.34 ± 0.35 N.m). See Fig 19±2.

*209 | 218* | |

POLY | ||

LEATHER | ||

Lips must | ||

Lips must | face down | |

face down |

| |

*211 |

| |

224 | 203* | |

*213 | 214 |

NOTE: NOTE THE ALIGNMENT of the piston (224) to the nut (214). Maintain this alignment through- out Steps 2, 3 and 4.

3.Apply 1 drop only of sealant, supplied with the repair kit, to the piston valve threads. Place the small ball (203*) on the valve. See Fig 19±2. Hand tighten the valve into the rod (223) just until the nut contacts the rod. Place the flats of the displacement rod in a vise.

*208 | 217* |

LEATHER | |

Lips must | POLY |

face up | Lips must |

| face up |

*220 | 205* |

| |

*219 | Lips of seal |

| must face |

| down |

216 |

|

| 207* |

215 |

|

214

TORQUE NUT AGAINST ROD TO 19

DO NOT ALLOW THIS NUT TO MOVE RELATIVE TO THE PISTON (224) WHEN INSTALLING PISTON ONTO ROD

Fig 19±3

223

0083

*204 |

206* |

222 |

TORQUE TO |

80 ft±lb |

(107 N.m) |

Fig 19±1

Reassembly Procedure

1.Stack these parts one at a time onto the piston valve (224): backup washer (219*), U±cup seal (205*) lips down, and female gland (220*), alternate the polyeth- ylene and leather v±packings (217*, 208*) lips up, and then the male gland (213*). See Fig 19±1.

4.Torque the nut (214) against the rod (223) to 19 ft±lb (25 N.m). Use two wrenches to maintain the align- ment as mentioned in the NOTE above. See Fig 19±3.

5.Stack these parts one at a time into the top of the cyl- inder (216): male gland (211*), alternate the polyeth- ylene and leather v±packings (218*, 209*) lips down, and then the female gland (212*). See Fig 19±1.

6.Loosely install the packing nut (221) and plug (201).

7.Insert the oiled piston rod (223) through the bottom of the cylinder.

8.Assemble the intake valve. Use a new gasket (206*). Screw the intake valve into the cylinder and tighten to 80 ft±lb (107 N.m). See Fig 19±1.

9.Screw down the cylinder locknut (112) until it is finger tight at the bottom of the external cylinder threads. See Fig 19±1.

10.Install the displacement pump on the sprayer. See page18.