Maintenance

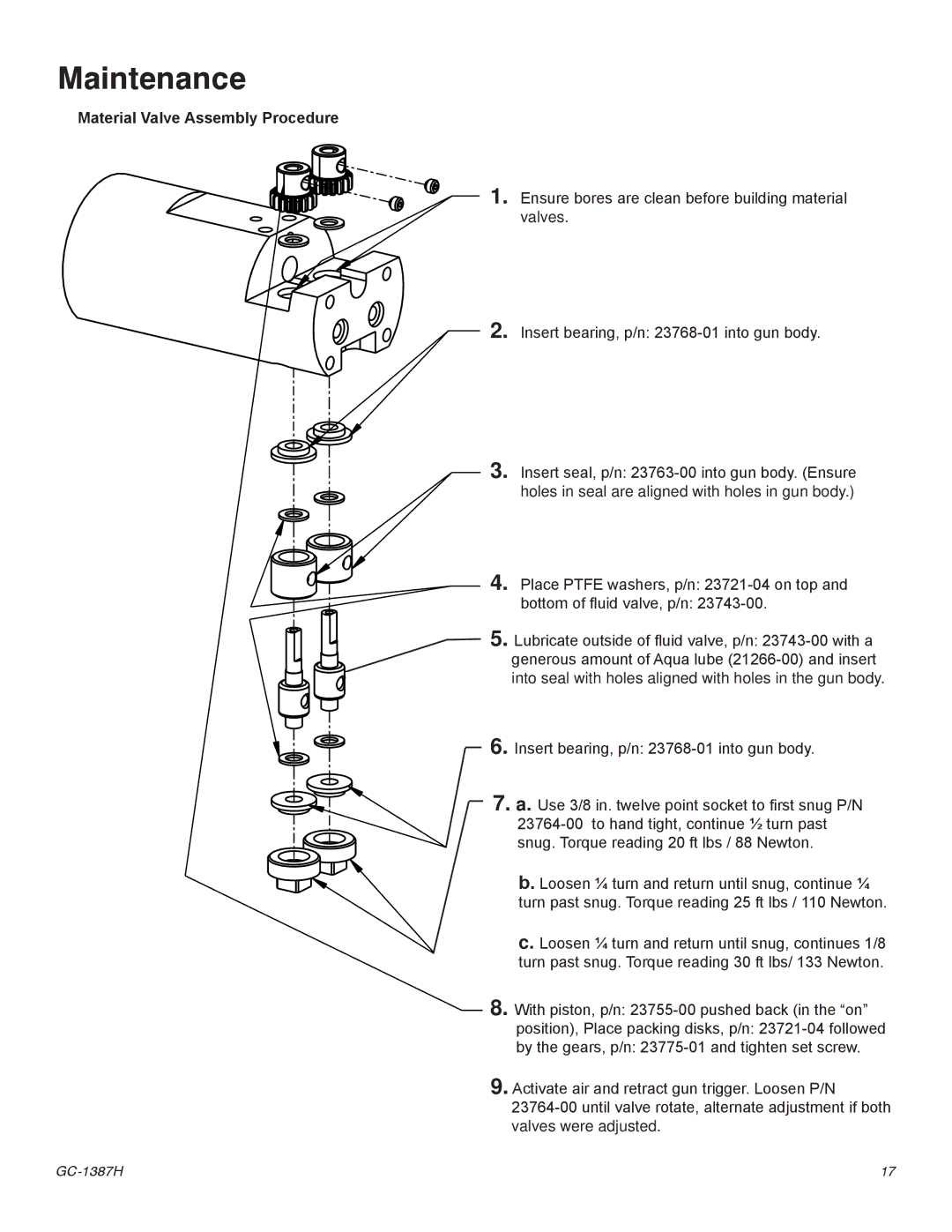

Material Valve Assembly Procedure

1. Ensure bores are clean before building material valves.

2. Insert bearing, p/n: 23768-01 into gun body.

3. Insert seal, p/n: 23763-00 into gun body. (Ensure holes in seal are aligned with holes in gun body.)

4. Place PTFE washers, p/n: 23721-04 on top and bottom of fluid valve, p/n: 23743-00.

5. Lubricate outside of fluid valve, p/n: 23743-00 with a generous amount of Aqua lube (21266-00) and insert into seal with holes aligned with holes in the gun body.

6. Insert bearing, p/n: 23768-01 into gun body.

7. a. Use 3/8 in. twelve point socket to first snug P/N 23764-00 to hand tight, continue ½ turn past snug. Torque reading 20 ft lbs / 88 Newton.

b. Loosen ¼ turn and return until snug, continue ¼ turn past snug. Torque reading 25 ft lbs / 110 Newton.

c. Loosen ¼ turn and return until snug, continues 1/8 turn past snug. Torque reading 30 ft lbs/ 133 Newton.

8. With piston, p/n: 23755-00 pushed back (in the “on” position), Place packing disks, p/n: 23721-04 followed by the gears, p/n: 23775-01 and tighten set screw.

9. Activate air and retract gun trigger. Loosen P/N 23764-00 until valve rotate, alternate adjustment if both valves were adjusted.