Pre Start-Up Checks

1.Check all fasteners for tightness. The wheel should rotate freely and not rub on the fan panel venturi. Turn the fan on momentarily to check for unusual vibration or noise. Do not run the fan more than a few seconds without being connected to the system for which it was designed. Motor overloading and burnout may result from lack of system static pressure.

2.Inlet and discharge collars are provided for duct connection. The inlet panel is removable for attaching optional filter box accessory.

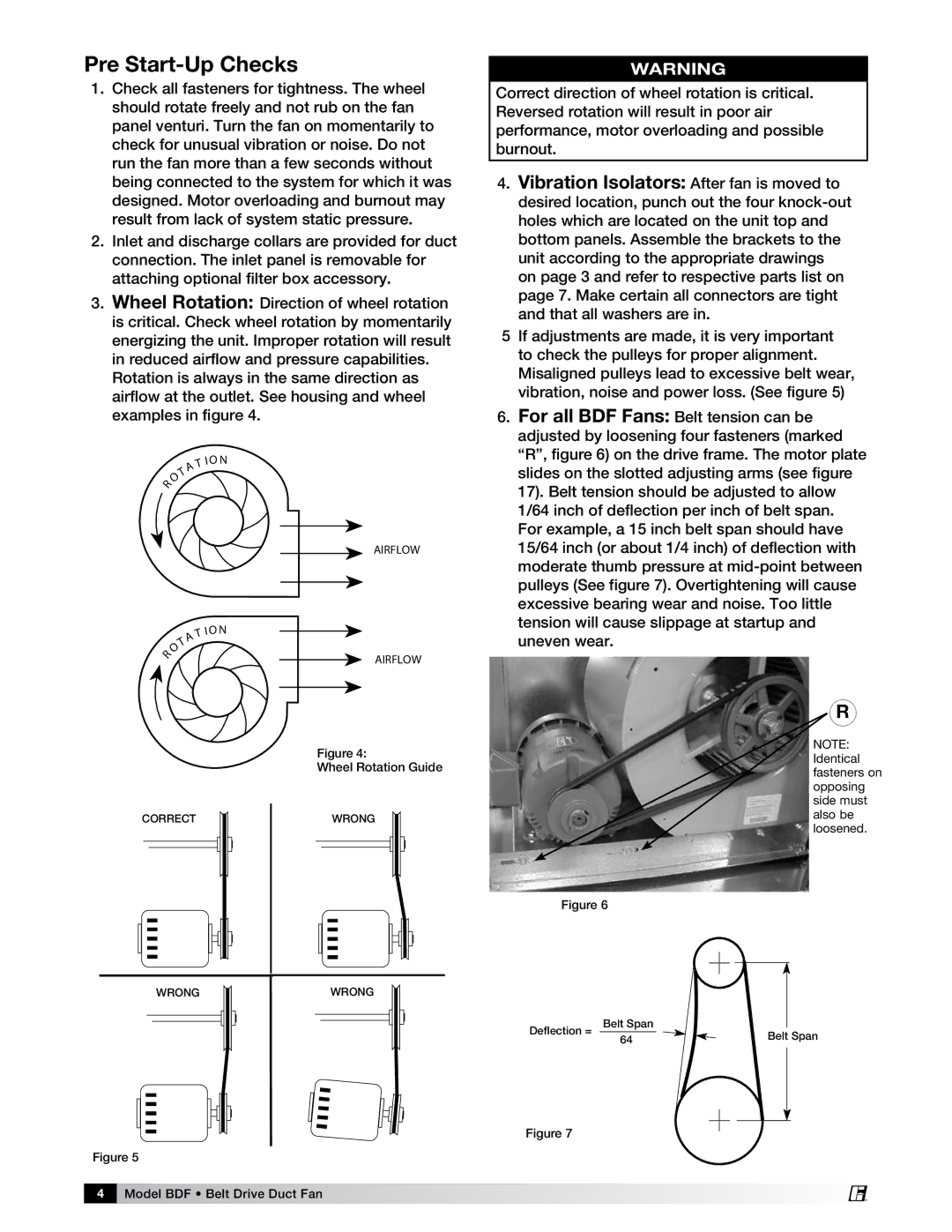

3.Wheel Rotation: Direction of wheel rotation is critical. Check wheel rotation by momentarily energizing the unit. Improper rotation will result in reduced airflow and pressure capabilities.

Rotation is always in the same direction as airflow at the outlet. See housing and wheel examples in figure 4.

ATIO N

T

RO

AIRFLOW

TIO N |

|

| |

|

| ||

A |

|

| |

T |

|

| |

O |

|

| |

R |

| AIRFLOW | |

| |||

|

|

| |

|

|

|

|

Figure 4:

Wheel Rotation Guide

CORRECTWRONG

WARNING

Correct direction of wheel rotation is critical. Reversed rotation will result in poor air performance, motor overloading and possible burnout.

4.Vibration Isolators: After fan is moved to

desired location, punch out the four

5If adjustments are made, it is very important to check the pulleys for proper alignment. Misaligned pulleys lead to excessive belt wear, vibration, noise and power loss. (See figure 5)

6.For all BDF Fans: Belt tension can be adjusted by loosening four fasteners (marked “R”, figure 6) on the drive frame. The motor plate slides on the slotted adjusting arms (see figure 17). Belt tension should be adjusted to allow 1/64 inch of deflection per inch of belt span.

For example, a 15 inch belt span should have 15/64 inch (or about 1/4 inch) of deflection with moderate thumb pressure at

R

NOTE:

Identical fasteners on opposing side must also be loosened.

Figure 6

WRONGWRONG

Deflection = | Belt Span | Belt Span |

| 64 | |

|

|

Figure 7

Figure 5

4

Model BDF • Belt Drive Duct Fan

®