1. DAMPER IS INSTALLED OUTSIDE OF WALL PLANE |

|

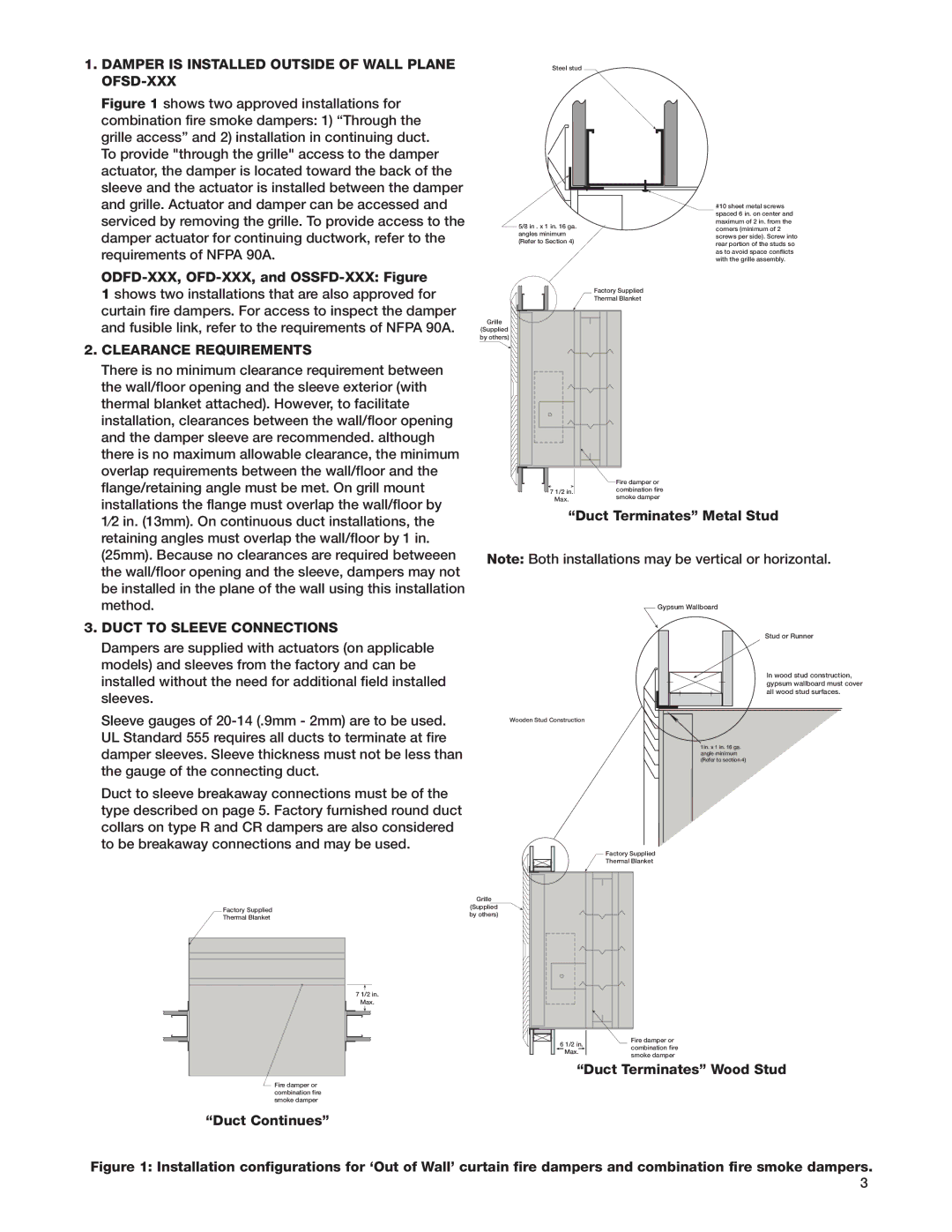

Figure 1 shows two approved installations for |

combination fire smoke dampers: 1) “Through the |

grille access” and 2) installation in continuing duct. |

To provide "through the grille" access to the damper |

actuator, the damper is located toward the back of the |

sleeve and the actuator is installed between the damper |

and grille. Actuator and damper can be accessed and |

serviced by removing the grille. To provide access to the |

damper actuator for continuing ductwork, refer to the |

requirements of NFPA 90A. |

|

1 shows two installations that are also approved for |

curtain fire dampers. For access to inspect the damper |

and fusible link, refer to the requirements of NFPA 90A. |

2. CLEARANCE REQUIREMENTS |

There is no minimum clearance requirement between |

the wall/floor opening and the sleeve exterior (with |

thermal blanket attached). However, to facilitate |

installation, clearances between the wall/floor opening |

and the damper sleeve are recommended. although |

there is no maximum allowable clearance, the minimum |

overlap requirements between the wall/floor and the |

flange/retaining angle must be met. On grill mount |

installations the flange must overlap the wall/floor by |

1⁄2 in. (13mm). On continuous duct installations, the |

retaining angles must overlap the wall/floor by 1 in. |

(25mm). Because no clearances are required betweeen |

the wall/floor opening and the sleeve, dampers may not |

be installed in the plane of the wall using this installation |

method. |

3. DUCT TO SLEEVE CONNECTIONS |

Steel stud

|

|

|

|

| #10 sheet metal screws |

|

|

|

|

| spaced 6 in. on center and |

| 5/8 in . x 1 in. 16 ga. |

|

|

| maximum of 2 in. from the |

|

|

|

| corners (minimum of 2 | |

| angles minimum |

|

|

| |

|

|

|

| screws per side). Screw into | |

| (Refer to Section 4) |

|

|

| |

|

|

|

| rear portion of the studs so | |

|

|

|

|

| |

|

|

|

|

| as to avoid space conflicts |

|

|

|

|

| with the grille assembly. |

|

| Factory Supplied | |||

|

| Thermal Blanket | |||

|

|

|

|

| Factory Supplied |

|

|

|

|

| |

Grille |

|

|

|

| Thermal Blanket |

|

|

|

|

| |

(Supplied |

|

|

|

|

|

by others) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Fire damper or | Fire damper or | |

7 1/2 in. | combination fire | ||

combination fire | |||

smoke damper | |||

Max. | smoke damper | ||

|

“Duct Terminates” Metal Stud

Note: Both installations may be vertical or horizontal.

Gypsum Wallboard

Dampers are supplied with actuators (on applicable |

models) and sleeves from the factory and can be |

installed without the need for additional field installed |

sleeves. |

Sleeve gauges of |

UL Standard 555 requires all ducts to terminate at fire |

damper sleeves. Sleeve thickness must not be less than |

the gauge of the connecting duct. |

Duct to sleeve breakaway connections must be of the |

type described on page 5. Factory furnished round duct |

collars on type R and CR dampers are also considered |

to be breakaway connections and may be used. |

Wooden Stud Construction

Stud or Runner

In wood stud construction, gypsum wallboard must cover all wood stud surfaces.

1in. x 1 in. 16 ga. angle minimum (Refer to section 4)

Factory Supplied Thermal Blanket

| Grille | |

Factory Supplied | (Supplied | |

by others) | ||

Thermal Blanket | ||

|

7 1/2 in.

Max.

6 1/2 in. | Fire damper or | |

combination fire | ||

Max. | ||

smoke damper | ||

|

“Duct Terminates” Wood Stud

re | Fire damper or | |

combination fire | ||

r | ||

smoke damper | ||

|

“Duct Continues”