SQ/BSQ specifications

The Greenheck Fan SQ/BSQ series represents a significant advancement in the realm of ventilation solutions, designed to cater to both commercial and industrial applications. With an emphasis on performance, efficiency, and reliability, these fans have become a go-to choice for engineers and contractors alike.One of the main features of the SQ/BSQ series is their advanced airflow design. The fans are engineered with high-performance backward-inclined blades, which not only optimize airflow but also minimize noise levels, making them ideal for settings where quiet operation is essential. This design allows the SQ/BSQ fans to handle a wide range of static pressures, delivering consistent airflow even in varying conditions.

Another notable characteristic of the SQ/BSQ fans is their robust construction. Made with high-quality materials, these fans are built to withstand the rigors of industrial environments. The casings are typically constructed from galvanized steel, with optional coatings available for enhanced corrosion resistance. This durability ensures long-lasting performance, reducing the need for frequent replacements and maintenance.

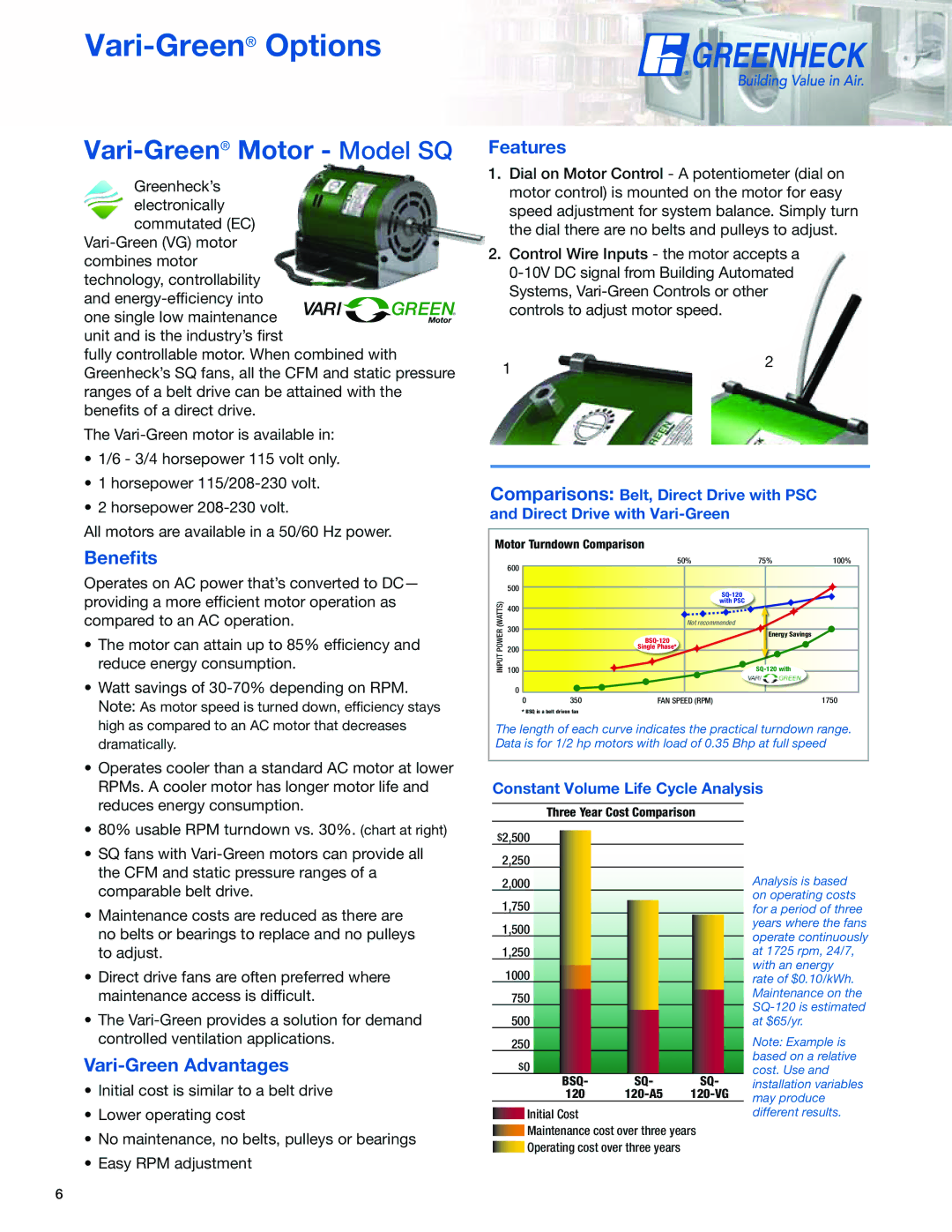

Equipped with the latest motor technology, the SQ/BSQ series offers energy-efficient options that comply with various energy standards. The fans utilize a range of motor types, including premium efficiency and electronically commutated motors (ECM), which contribute to lower operating costs and reduced energy consumption. This focus on energy efficiency aligns with increasing regulatory requirements and environmental considerations.

The SQ/BSQ series also embraces advanced control technologies. Through the integration of variable frequency drives (VFD), users can achieve precise control over fan speed and airflow, allowing for better system optimization. This capability is particularly beneficial in applications where airflow demands fluctuate, ensuring that energy usage remains efficient.

Lastly, Greenheck has prioritized ease of installation and maintenance with the SQ/BSQ models. The fans are designed to facilitate quick installation, featuring accessible service points for maintenance tasks. This ease of access helps reduce downtime and improves overall operational efficiency.

In summary, the Greenheck Fan SQ/BSQ series combines advanced airflow design, robust construction, energy-efficient motor technology, and intelligent control options to deliver a comprehensive and reliable ventilation solution. Whether used in commercial buildings, warehouses, or industrial facilities, these fans stand out for their performance and versatility, making them a preferred choice in the ventilation market.