Installation Practices (Continued)

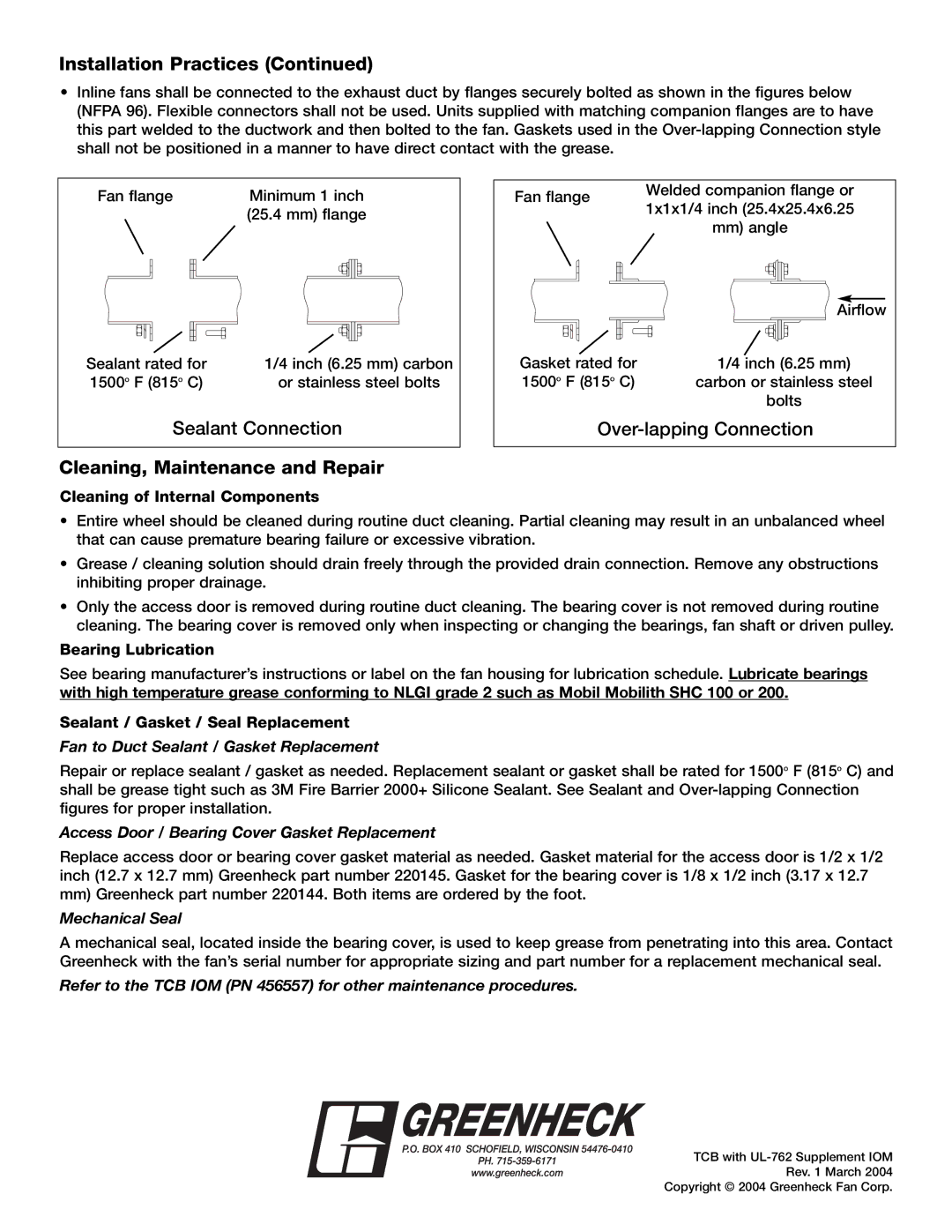

•Inline fans shall be connected to the exhaust duct by flanges securely bolted as shown in the figures below (NFPA 96). Flexible connectors shall not be used. Units supplied with matching companion flanges are to have this part welded to the ductwork and then bolted to the fan. Gaskets used in the

Fan flange | Minimum 1 inch |

| (25.4 mm) flange |

Sealant rated for | 1/4 inch (6.25 mm) carbon |

1500o F (815o C) | or stainless steel bolts |

Sealant Connection

Cleaning, Maintenance and Repair

Cleaning of Internal Components

Fan flange | Welded companion flange or | |

1x1x1/4 inch (25.4x25.4x6.25 | ||

| ||

| mm) angle |

| Airflow |

Gasket rated for | 1/4 inch (6.25 mm) |

1500o F (815o C) | carbon or stainless steel |

| bolts |

Over-lapping Connection

•Entire wheel should be cleaned during routine duct cleaning. Partial cleaning may result in an unbalanced wheel that can cause premature bearing failure or excessive vibration.

•Grease / cleaning solution should drain freely through the provided drain connection. Remove any obstructions inhibiting proper drainage.

•Only the access door is removed during routine duct cleaning. The bearing cover is not removed during routine cleaning. The bearing cover is removed only when inspecting or changing the bearings, fan shaft or driven pulley.

Bearing Lubrication

See bearing manufacturer’s instructions or label on the fan housing for lubrication schedule. Lubricate bearings with high temperature grease conforming to NLGI grade 2 such as Mobil Mobilith SHC 100 or 200.

Sealant / Gasket / Seal Replacement

Fan to Duct Sealant / Gasket Replacement

Repair or replace sealant / gasket as needed. Replacement sealant or gasket shall be rated for 1500o F (815o C) and shall be grease tight such as 3M Fire Barrier 2000+ Silicone Sealant. See Sealant and

Access Door / Bearing Cover Gasket Replacement

Replace access door or bearing cover gasket material as needed. Gasket material for the access door is 1/2 x 1/2 inch (12.7 x 12.7 mm) Greenheck part number 220145. Gasket for the bearing cover is 1/8 x 1/2 inch (3.17 x 12.7

mm)Greenheck part number 220144. Both items are ordered by the foot.

Mechanical Seal

A mechanical seal, located inside the bearing cover, is used to keep grease from penetrating into this area. Contact Greenheck with the fan’s serial number for appropriate sizing and part number for a replacement mechanical seal.

Refer to the TCB IOM (PN 456557) for other maintenance procedures.

TCB with