Vektor-HS, Vektor-H specifications

Greenheck Fan Corporation, a leader in air movement and control equipment, has developed the Vektor-H and Vektor-HS series to meet the growing demands for energy efficiency and performance in commercial and industrial ventilation systems. These models are specifically designed to provide optimal airflow while minimizing energy consumption.The Vektor-H model stands out with its innovative backward-inclined centrifugal fan wheel, which effectively handles air volumes ranging from 1,000 to 150,000 CFM. This design minimizes turbulence and enhances performance, ensuring quiet operation even at high speeds. The Vektor-H also features a direct drive option that eliminates the need for belts and sheaves, reducing maintenance while increasing reliability. The inclusion of a high-efficiency motor further exemplifies its commitment to energy savings.

On the other hand, the Vektor-HS, or High-Static version, is designed for applications requiring higher static pressure. This capability makes it ideal for systems where long duct runs or highly restrictive applications are involved. With airflow capabilities similar to the Vektor-H, the Vektor-HS is capable of operating efficiently in conditions that demand advanced pressure performance.

Both models come equipped with Greenheck’s advanced controls and monitoring systems, which provide real-time data on performance metrics. These features allow facility managers to optimize the system based on actual operating conditions, thereby improving energy efficiency and reducing operational costs.

Technologically, the Vektor-H and Vektor-HS series utilize advanced acoustic design principles, which significantly reduce noise levels. The application of sound-dampening materials and strategically designed fan casings helps in achieving a quieter working environment, addressing one of the common concerns in HVAC systems.

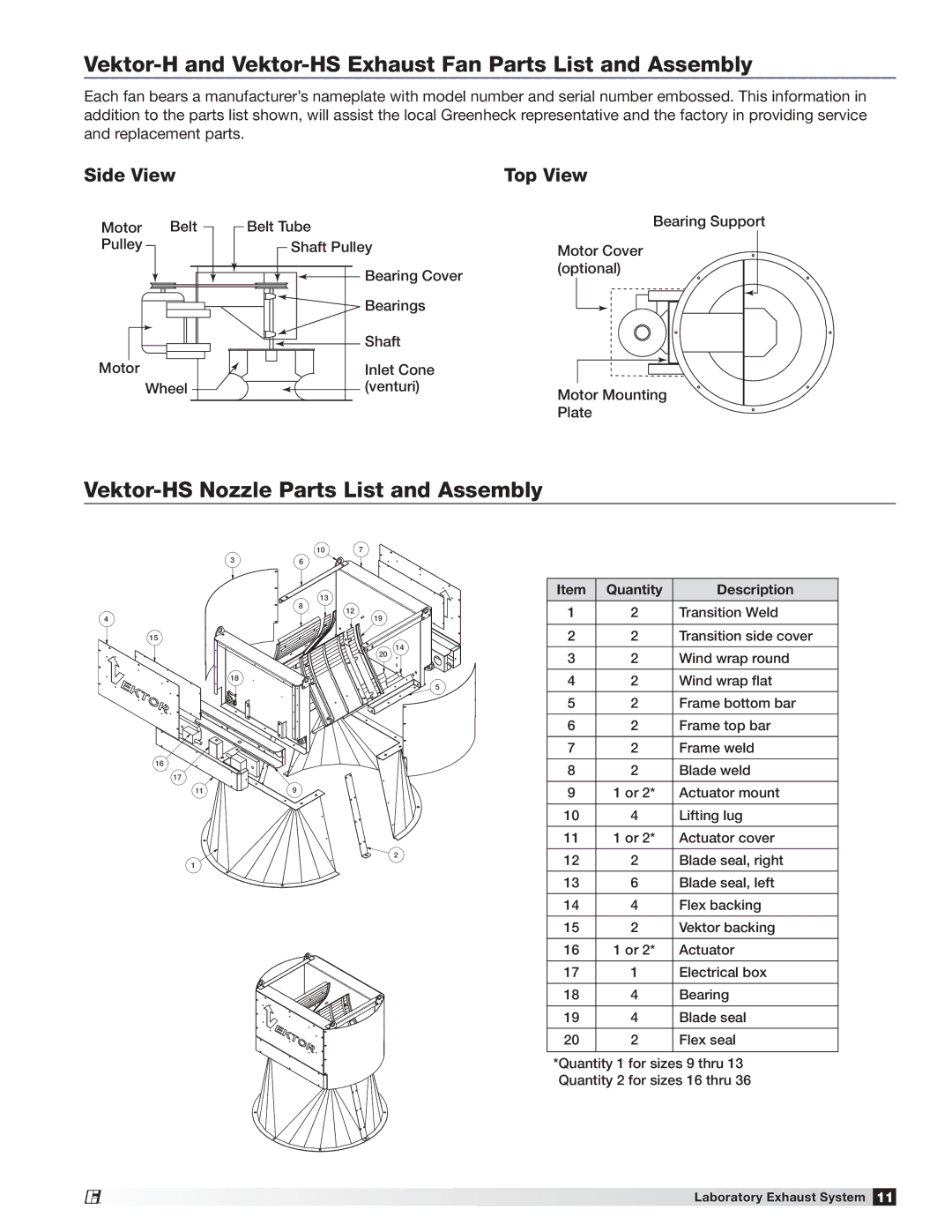

Furthermore, the Greenheck Vektor series is built with durability in mind. The construction involves heavy-gauge steel and corrosion-resistant finishes, ensuring long-lasting performance even in harsh environments. Both the Vektor-H and Vektor-HS are also customizable, allowing for modifications to meet specific application requirements, such as different mounting configurations and discharge orientations.

In summary, the Greenheck Vektor-H and Vektor-HS series represent the fusion of advanced technology with practical applications, resulting in efficient, durable, and quiet ventilation solutions suitable for a variety of industrial and commercial settings. These models not only address the current needs for energy efficiency and performance but also position users favorably for future advancements in HVAC technology.