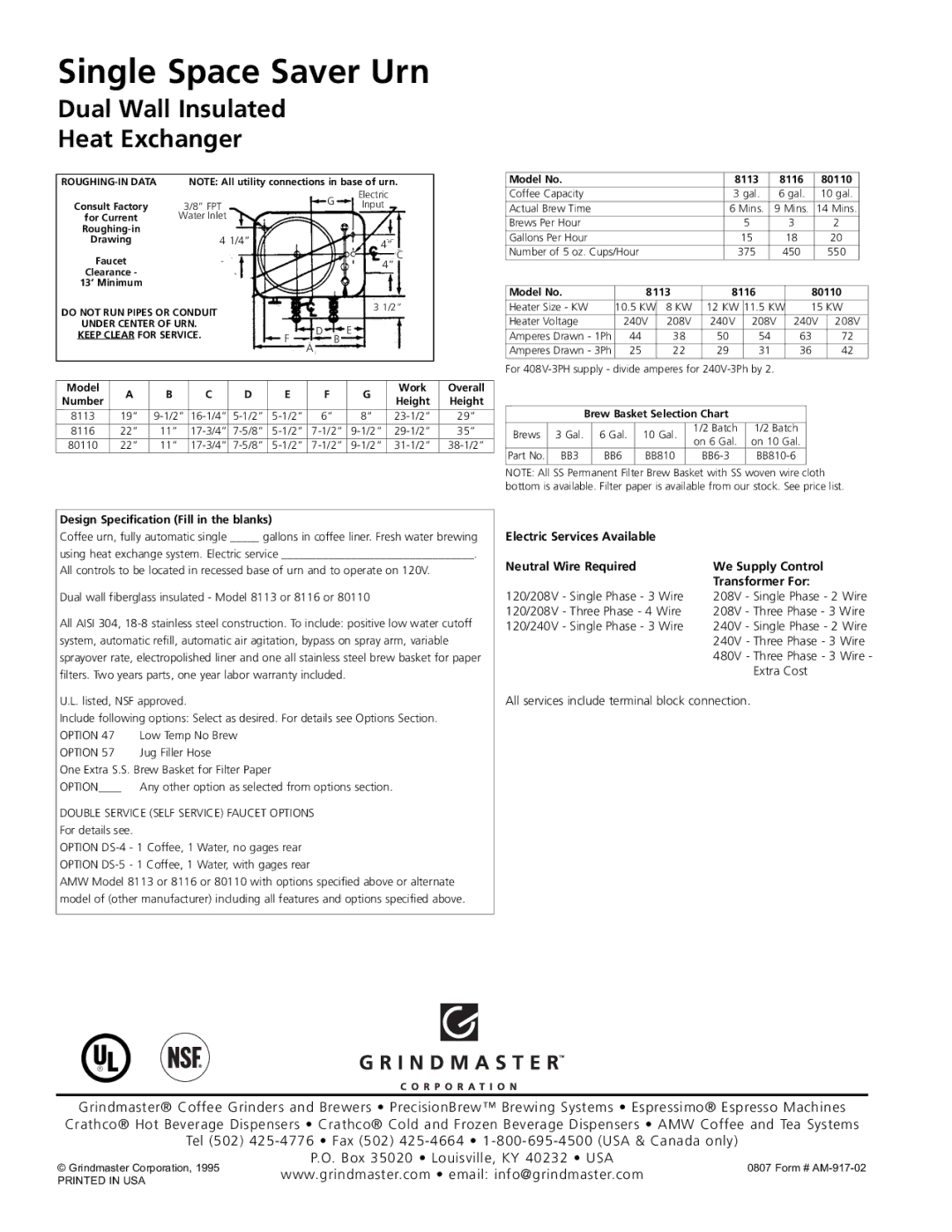

8116, 80110 specifications

The Grindmaster 80110 and 8116 are two high-performance coffee dispensers engineered to meet the demands of commercial settings. Both models are celebrated for their innovative designs and advanced technologies, making them ideal choices for cafés, restaurants, and convenience stores.The Grindmaster 80110 stands out with its sleek design and user-friendly interface. It features a high-capacity hopper that can hold a sizable amount of coffee grounds, reducing the need for frequent refills. The model incorporates a precision brewing system that ensures optimal extraction and flavor profile for every cup, thanks to its adjustable brew time and temperature settings. Additionally, the 80110 has a programmable touchscreen that allows users to customize their brewing preferences and save their favorite settings. This feature not only enhances the user experience but also ensures consistent quality in every brew.

On the other hand, the Grindmaster 8116 is designed for those who need versatility and high output. This model boasts a dual-brew function, enabling users to brew both regular and decaf coffee simultaneously. Its energy-efficient design helps reduce operational costs, making it a perfect fit for busy establishments. The 8116 features an advanced digital control panel that offers real-time monitoring of brewing parameters, providing users with complete control over the brewing process. Additionally, its large water reservoir ensures that high-demand periods are easily supported, allowing for uninterrupted service.

Both models utilize advanced thermal retention technologies that keep brewed coffee at the optimal serving temperature for extended periods. Their stainless-steel construction ensures durability and easy maintenance, while the sleek finishes provide a modern aesthetic that fits seamlessly into any décor. The smart design of these dispensers includes easy-access components for maintenance, minimizing downtime and maximizing efficiency in fast-paced environments.

In conclusion, the Grindmaster 80110 and 8116 are exemplary coffee dispensers that combine advanced technologies and user-friendly features. Their ability to consistently deliver high-quality coffee while accommodating the demands of busy commercial settings makes them a smart investment for any establishment focused on providing an exceptional coffee experience.