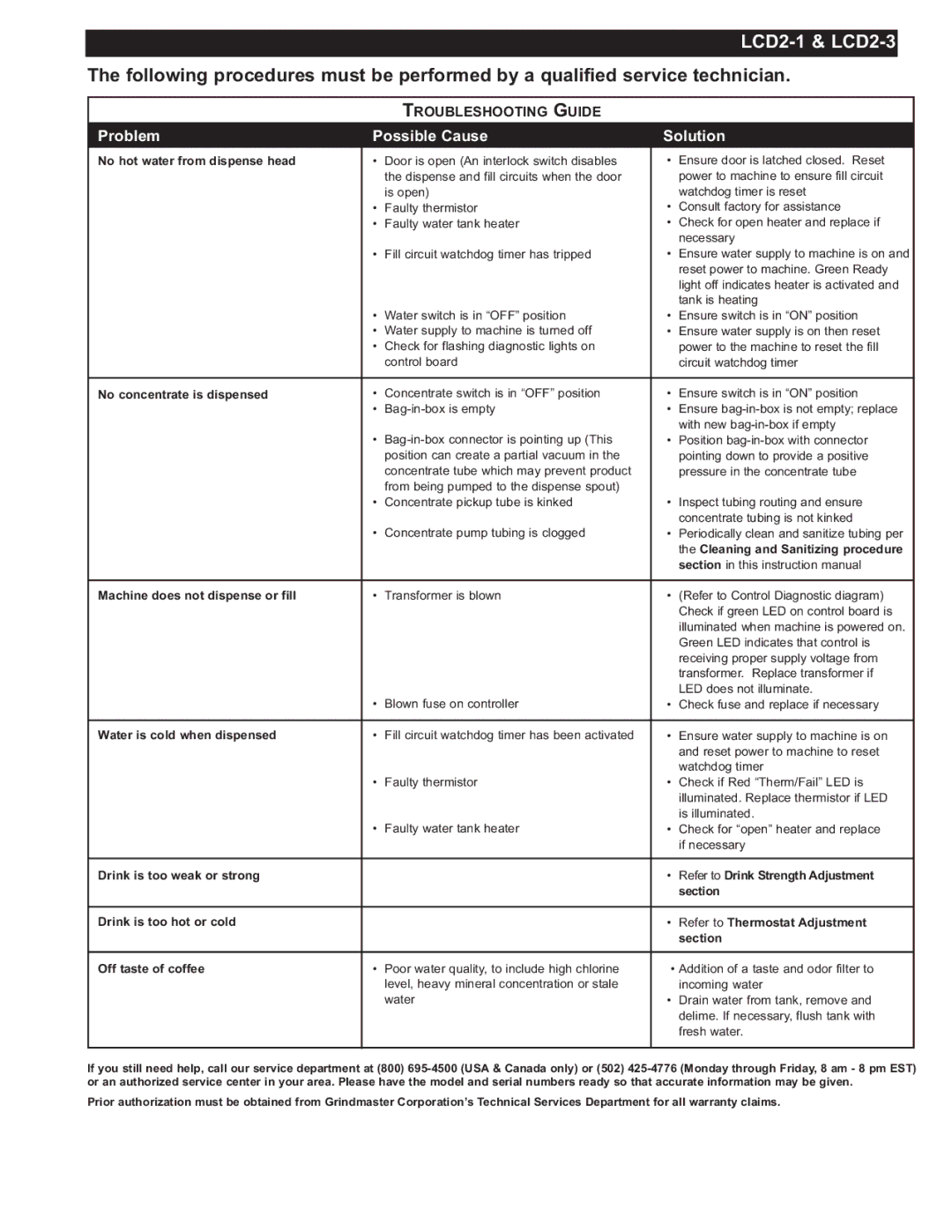

LCD2-1 & LCD2-3

The following procedures must be performed by a qualified service technician.

TROUBLESHOOTING GUIDE

Problem | Possible Cause | Solution | ||

No hot water from dispense head | • | Door is open (An interlock switch disables | • | Ensure door is latched closed. Reset |

|

| the dispense and fill circuits when the door |

| power to machine to ensure fill circuit |

|

| is open) |

| watchdog timer is reset |

| • | Faulty thermistor | • | Consult factory for assistance |

| • | Faulty water tank heater | • | Check for open heater and replace if |

|

|

|

| necessary |

| • | Fill circuit watchdog timer has tripped | • | Ensure water supply to machine is on and |

|

|

|

| reset power to machine. Green Ready |

|

|

|

| light off indicates heater is activated and |

|

|

|

| tank is heating |

| • | Water switch is in “OFF” position | • | Ensure switch is in “ON” position |

| • | Water supply to machine is turned off | • | Ensure water supply is on then reset |

| • | Check for flashing diagnostic lights on |

| power to the machine to reset the fill |

|

| control board |

| circuit watchdog timer |

|

|

|

|

|

No concentrate is dispensed | • | Concentrate switch is in “OFF” position | • | Ensure switch is in “ON” position |

| • | • | Ensure | |

|

|

|

| with new |

| • | • | Position | |

|

| position can create a partial vacuum in the |

| pointing down to provide a positive |

|

| concentrate tube which may prevent product |

| pressure in the concentrate tube |

|

| from being pumped to the dispense spout) |

|

|

| • | Concentrate pickup tube is kinked | • | Inspect tubing routing and ensure |

|

|

|

| concentrate tubing is not kinked |

| • | Concentrate pump tubing is clogged | • | Periodically clean and sanitize tubing per |

|

|

|

| the Cleaning and Sanitizing procedure |

|

|

|

| section in this instruction manual |

|

|

|

|

|

Machine does not dispense or fill | • | Transformer is blown | • | (Refer to Control Diagnostic diagram) |

|

|

|

| Check if green LED on control board is |

|

|

|

| illuminated when machine is powered on. |

|

|

|

| Green LED indicates that control is |

|

|

|

| receiving proper supply voltage from |

|

|

|

| transformer. Replace transformer if |

|

|

|

| LED does not illuminate. |

| • | Blown fuse on controller | • | Check fuse and replace if necessary |

|

|

|

|

|

Water is cold when dispensed | • | Fill circuit watchdog timer has been activated | • | Ensure water supply to machine is on |

|

|

|

| and reset power to machine to reset |

|

|

|

| watchdog timer |

| • | Faulty thermistor | • | Check if Red “Therm/Fail” LED is |

|

|

|

| illuminated. Replace thermistor if LED |

|

|

|

| is illuminated. |

| • | Faulty water tank heater | • | Check for “open” heater and replace |

|

|

|

| if necessary |

|

|

|

| |

Drink is too weak or strong |

|

| • Refer to Drink Strength Adjustment | |

|

|

|

| section |

|

|

|

|

|

Drink is too hot or cold |

|

| • | Refer to Thermostat Adjustment |

|

|

|

| section |

|

|

|

| |

Off taste of coffee | • | Poor water quality, to include high chlorine | • Addition of a taste and odor filter to | |

|

| level, heavy mineral concentration or stale |

| incoming water |

|

| water | • | Drain water from tank, remove and |

|

|

|

| delime. If necessary, flush tank with |

|

|

|

| fresh water. |

|

|

|

|

|

If you still need help, call our service department at (800)

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all warranty claims.