INSTRUCTIONS FOR C1367

FINGER JOINT BIT

•Failure to follow theSE guide- lines will result in serious per- sonal injury.

•ALWAYS WEAR ANSI APPROVED EYE AND EAR PROTECTION WHEN USING THIS BIT.

•The use of a router table is strongly recommended.

•Never feed lumber with the rotation of the bit.

•Follow the safety guidelines set forth by the manufacturer of the router and router table.

These router bits have sharp edges. use care while removing the waxy protective coating. Never turn on the router with the protective coating still on the bit.

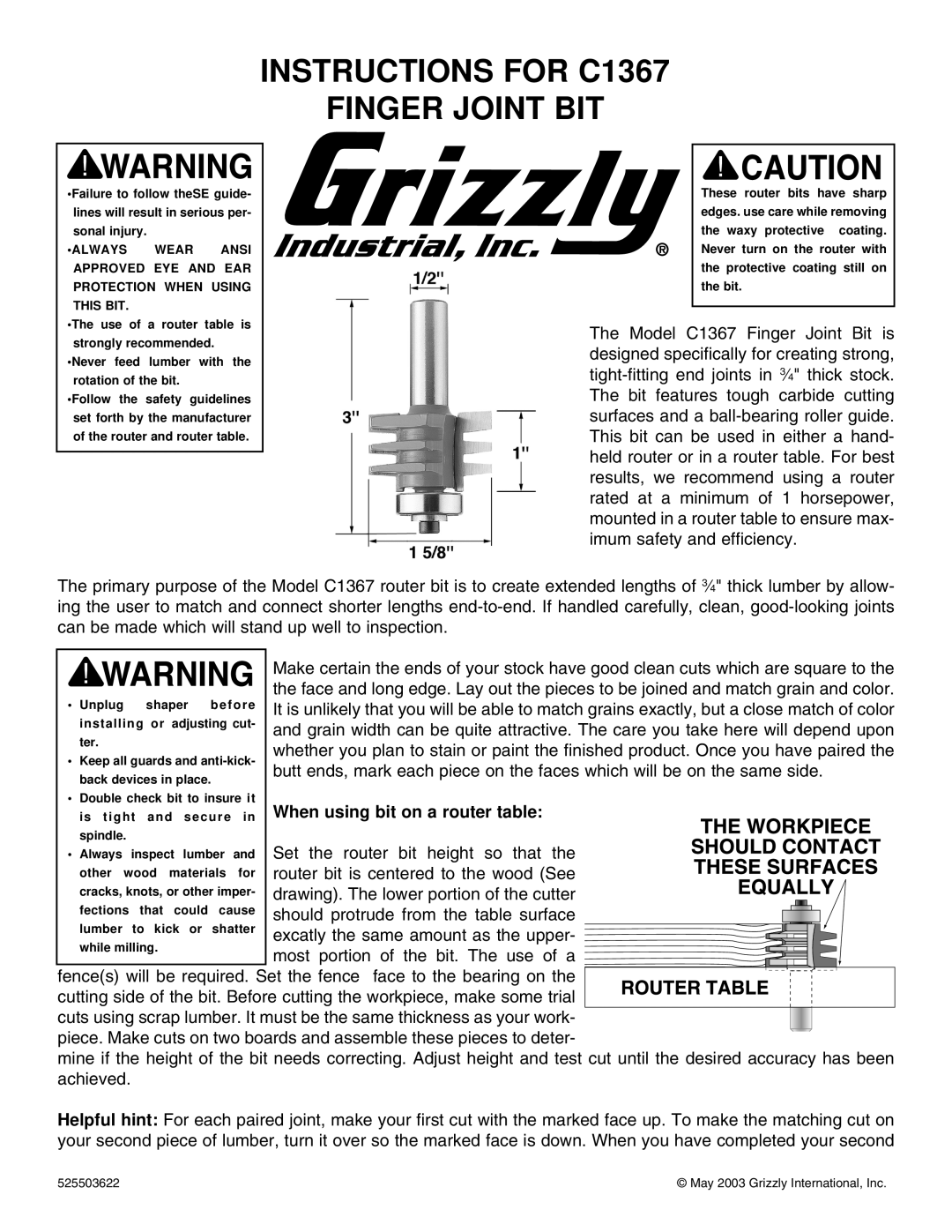

The Model C1367 Finger Joint Bit is designed specifically for creating strong,

The primary purpose of the Model C1367 router bit is to create extended lengths of 3⁄4" thick lumber by allow- ing the user to match and connect shorter lengths

|

|

|

|

|

| Make certain the ends of your stock have good clean cuts which are square to the | ||||||||||||

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

| the face and long edge. Lay out the pieces to be joined and match grain and color. | ||||||||||||

• Unplug | shaper | before | ||||||||||||||||

It is unlikely that you will be able to match grains exactly, but a close match of color | ||||||||||||||||||

| installing or adjusting cut- | and grain width can be quite attractive. The care you take here will depend upon | ||||||||||||||||

| ter. |

|

|

|

| |||||||||||||

|

|

|

|

| whether you plan to stain or paint the finished product. Once you have paired the | |||||||||||||

• | Keep all guards and | |||||||||||||||||

butt ends, mark each piece on the faces which will be on the same side. | ||||||||||||||||||

| back devices in place. | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

• | Double check bit to insure it | When using bit on a router table: |

|

| ||||||||||||||

| is tight and secure in |

|

| |||||||||||||||

|

| |||||||||||||||||

| spindle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| Set the router bit height so that the | |||||||||||||

• Always inspect lumber and | ||||||||||||||||||

| other wood materials for | router bit is centered to the wood (See | ||||||||||||||||

| cracks, knots, or other imper- | drawing). The lower portion of the cutter | ||||||||||||||||

| fections | that could | cause | should protrude from the table surface |

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

| |||||||||

| lumber | to kick or | shatter | excatly the same amount as the upper- |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| ||||||||

| while milling. |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

| most portion of the bit. The use of a |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

fence(s) will be required. Set the fence face to the bearing on the | ||||||||||||||||||

cutting side of the bit. Before cutting the workpiece, make some trial | ||||||||||||||||||

cuts using scrap lumber. It must be the same thickness as your work- piece. Make cuts on two boards and assemble these pieces to deter-

mine if the height of the bit needs correcting. Adjust height and test cut until the desired accuracy has been achieved.

Helpful hint: For each paired joint, make your first cut with the marked face up. To make the matching cut on your second piece of lumber, turn it over so the marked face is down. When you have completed your second

525503622 | © May 2003 Grizzly International, Inc. |