5.Use a straightedge to align the fences with the edge of the guide bearing.

6.Align the bottom edge of the shaper cutter with the top, or slightly below the top of the table.

7.Before turning the shaper ON, place a test rail on against the miter gauge finished face up and slide it against the fence.

8.Turn ON the shaper and slide the miter gauge and test rail through the shaper cutter as shown in Figure B.

These instructions are intended for COUNTERCLOCKWISE spindle operation only. DO NOT operate the shaper in the clockwise direction to make a climb cut. If this warning is ignored, the workpiece can kick forward, and may pull the hand into the shaper cutter, causing severe injury or death!

Cutting Stiles

To cut the stile edges:

1.Unplug the shaper!

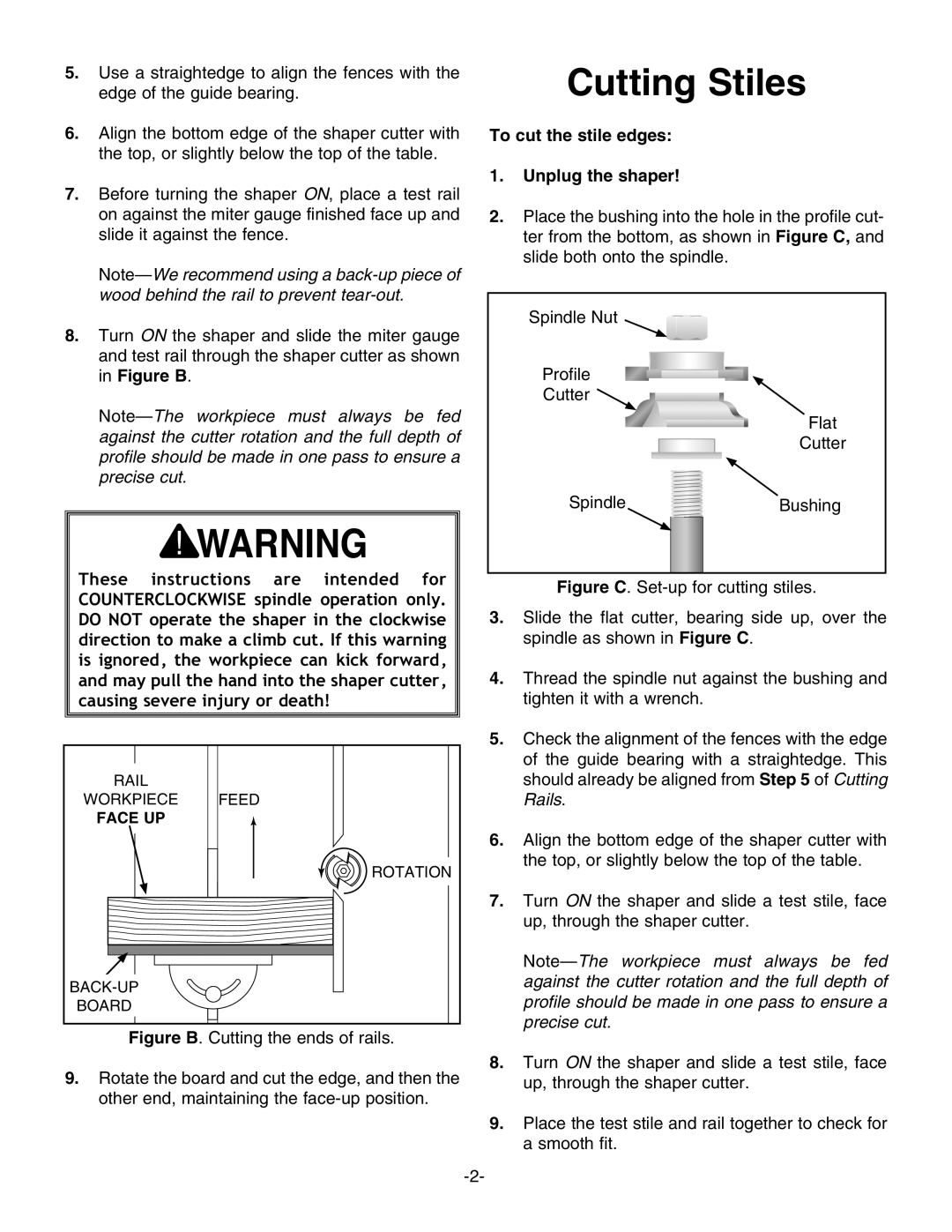

2.Place the bushing into the hole in the profile cut- ter from the bottom, as shown in Figure C, and slide both onto the spindle.

Spindle Nut

Profile

Cutter ![]()

Flat

Cutter

SpindleBushing

Figure C. Set-up for cutting stiles.

3. | Slide the flat cutter, bearing side up, over the |

| spindle as shown in Figure C. |

4. | Thread the spindle nut against the bushing and |

| tighten it with a wrench. |

5. | Check the alignment of the fences with the edge |

| of the guide bearing with a straightedge. This |

RAIL

WORKPIECE

FACE UP

FEED

![]() ROTATION

ROTATION

| should already be aligned from Step 5 of Cutting |

| Rails. |

6. | Align the bottom edge of the shaper cutter with |

| the top, or slightly below the top of the table. |

7. | Turn ON the shaper and slide a test stile, face |

| up, through the shaper cutter. |

|

BOARD

Figure B. Cutting the ends of rails.

9.Rotate the board and cut the edge, and then the other end, maintaining the face-up position.

| against the cutter rotation and the full depth of |

| profile should be made in one pass to ensure a |

| precise cut. |

8. | Turn ON the shaper and slide a test stile, face |

| up, through the shaper cutter. |

9. | Place the test stile and rail together to check for |

| a smooth fit. |