SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Loose mounting bolts.

•Worn switch.

•Worn or damaged cords or plugs.

•Damaged

•Any other unsafe condition.

DO NOT attempt to investigate or adjust any features of the machine while it is run- ning. Wait until the machine is turned OFF, unplugged, and all working parts have come to a rest before you do anything!

Lubrication

The chain should be lubricated periodically with a light machine oil. Motor bearings need no lubri- cation. Use only adequate lubrication. Too much lubricant will attract dirt and sawdust and will clog the chain mechanism.

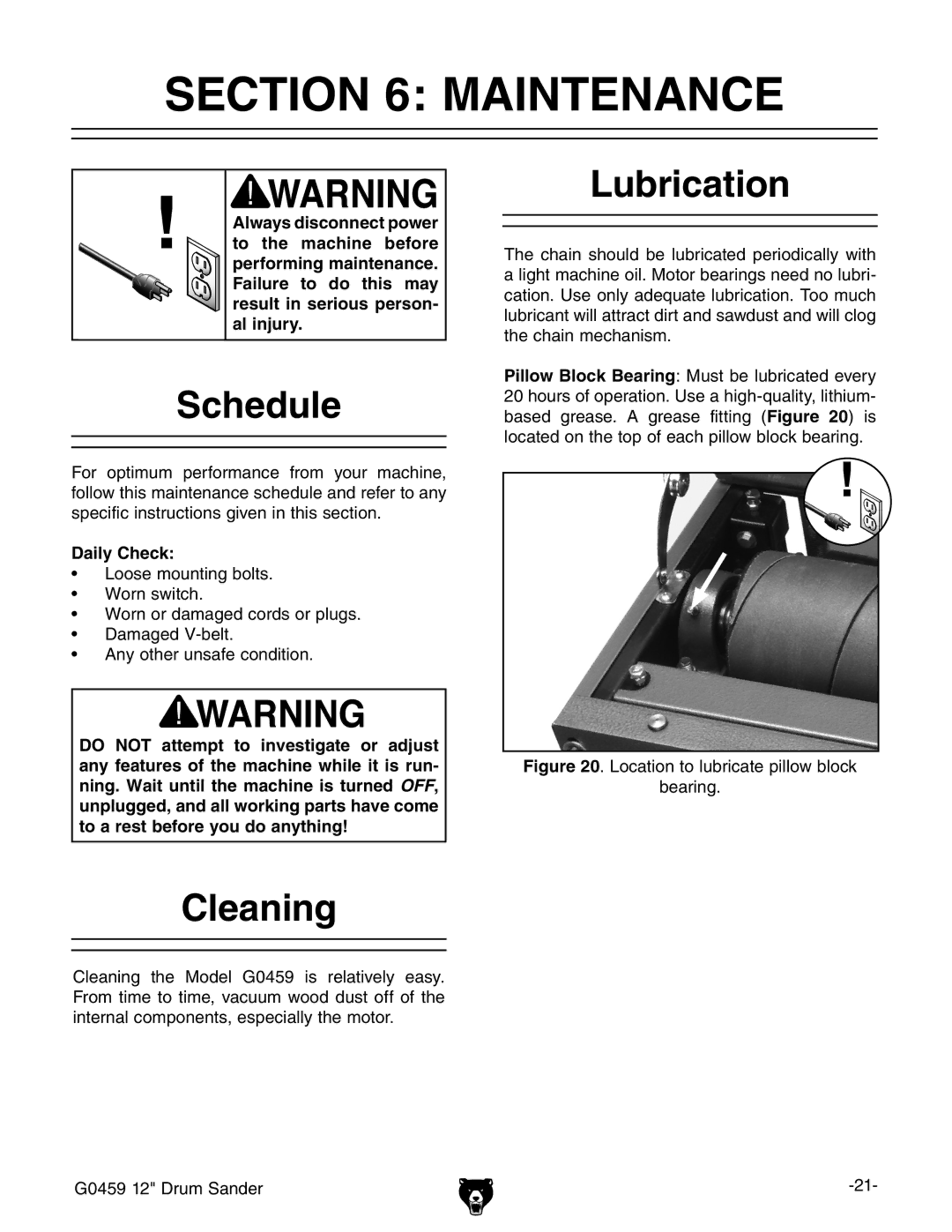

Pillow Block Bearing: Must be lubricated every

20hours of operation. Use a

Figure 20. Location to lubricate pillow block

bearing.

Cleaning

Cleaning the Model G0459 is relatively easy. From time to time, vacuum wood dust off of the internal components, especially the motor.

G0459 12" Drum Sander |