11.Mark the top of the table lift screws with arrows (all pointing in same direction) and mark the screws with liquid correction fluid above the mounting bracket (Figure 45). Later, when you reassemble the conveyor table, you can use these marks to reset the table height close to the current position.

Figure 45. Locations to mark table lift screws.

12.Mark the chain and sprockets with correction fluid.

13.Loosen the idler roller sprocket (Figure 38), carefully pull the chain off of all the sprockets, and remove it from the cabinet.

14.Loosen the conveyor belt at the front adjust- ments, as shown in Figure 46.

Figure 46. Conveyor belt loosened at the front

adjustments (only one shown).

15.Disconnect the conveyor feed motor wires from the circuit board.

16.Remove the scale pointer.

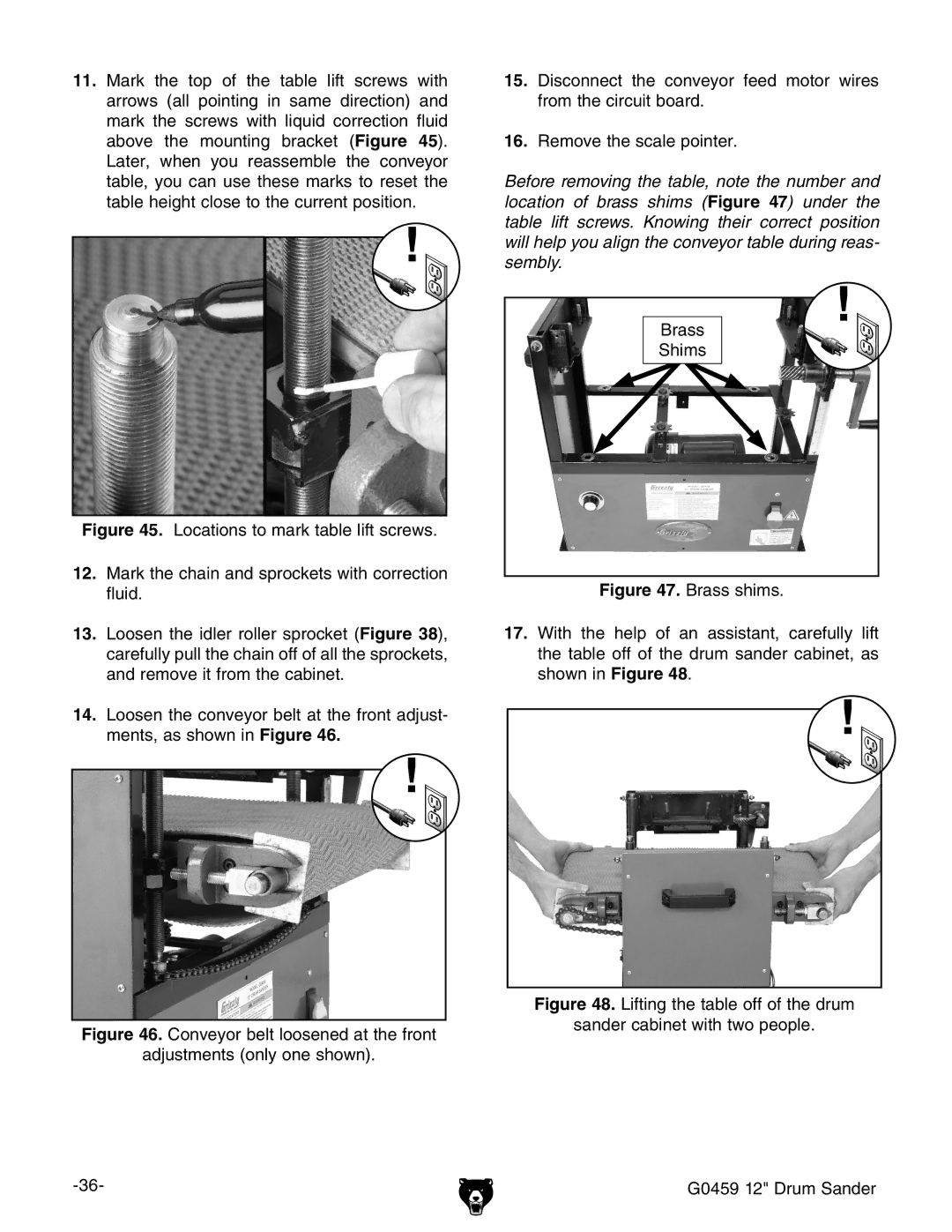

Before removing the table, note the number and location of brass shims (Figure 47) under the table lift screws. Knowing their correct position will help you align the conveyor table during reas- sembly.