Worm

Gear

Figure 23. Gearbox fill point.

Figure 24. Gearbox oil drain point.

Drive Chain—The drive chain should be inspect- ed and lubricated monthly. Check the sprocket, the chain and the cotter pin during inspection. Use a general purpose grease. Some chains will have master links instead of cotter pins.

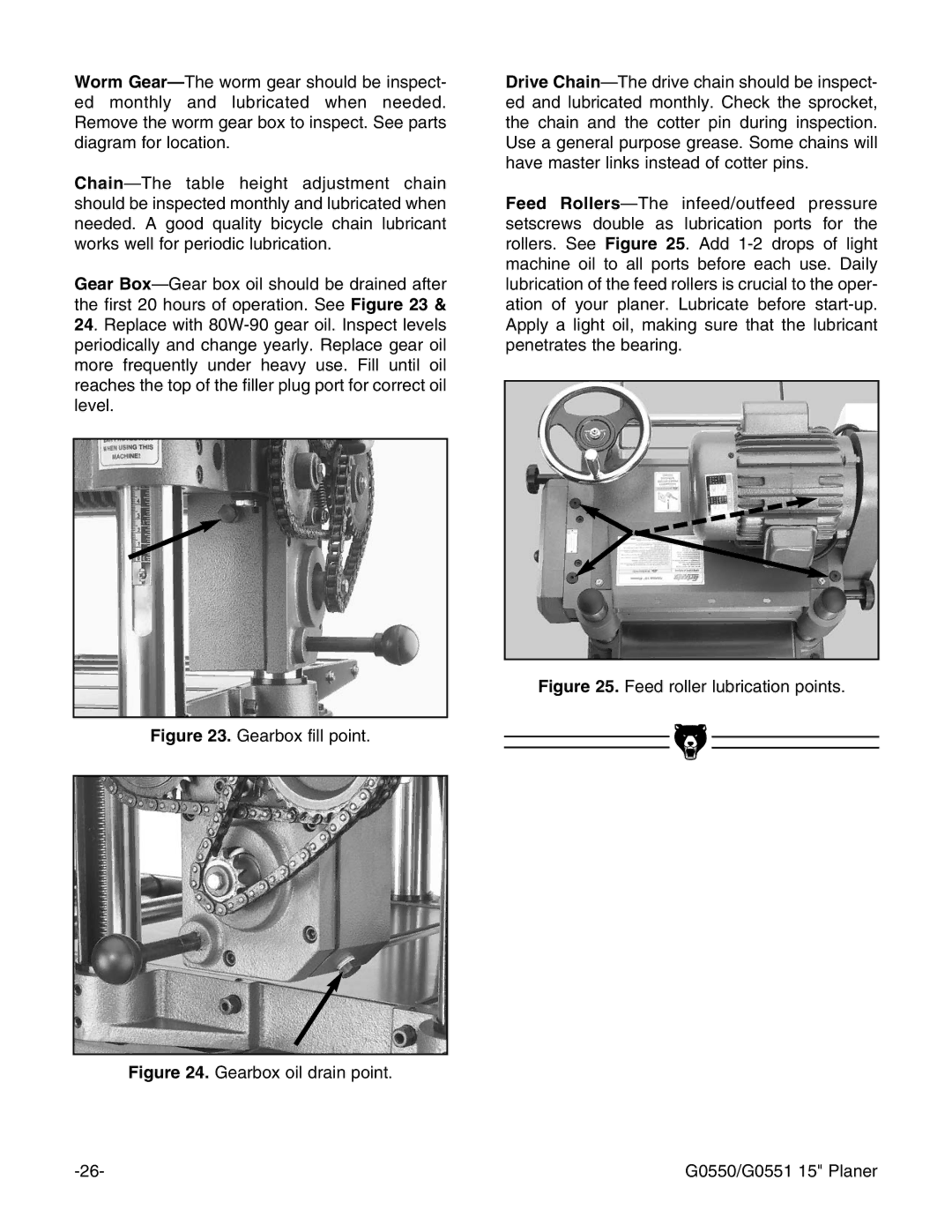

Feed Rollers—The infeed/outfeed pressure setscrews double as lubrication ports for the rollers. See Figure 25. Add 1-2 drops of light machine oil to all ports before each use. Daily lubrication of the feed rollers is crucial to the oper- ation of your planer. Lubricate before start-up. Apply a light oil, making sure that the lubricant penetrates the bearing.

Figure 25. Feed roller lubrication points.

G0550/G0551 15" Planer |