SECTION 4: OPERATIONS

Operation Safety

Damage to your eyes, lungs, and ears could result from using this machine without proper protective gear. Always wear safety glasses, a respirator, and hearing protection when operating this machine.

Loose hair and cloth-

ing could get caught in

machinery and cause seri-

machinery and cause seri-

ous personal injury. Keep

loose clothing and long

hair away from moving machinery.

NOTICE

If you have never used this type of machine or equipment before, WE STRONGLY REC- OMMEND that you read books, trade maga- zines, or get formal training before begin- ning any projects. Regardless of the con- tent in this section, Grizzly Industrial will not be held liable for accidents caused by lack of training.

Sanding Belts

There are many types of sanding belts to choose from. We recommend Aluminum Oxide for gen- eral workshop environments. Below is a chart that groups abrasives into different classes, and shows which grits fall into

Grit | Type |

Very Course | |

|

|

Course | |

|

|

Medium | |

|

|

Fine | |

|

|

Very Fine |

The general rule of thumb is to sand a workpiece with progressively higher grit numbers, with no one grit increase of more than 100.

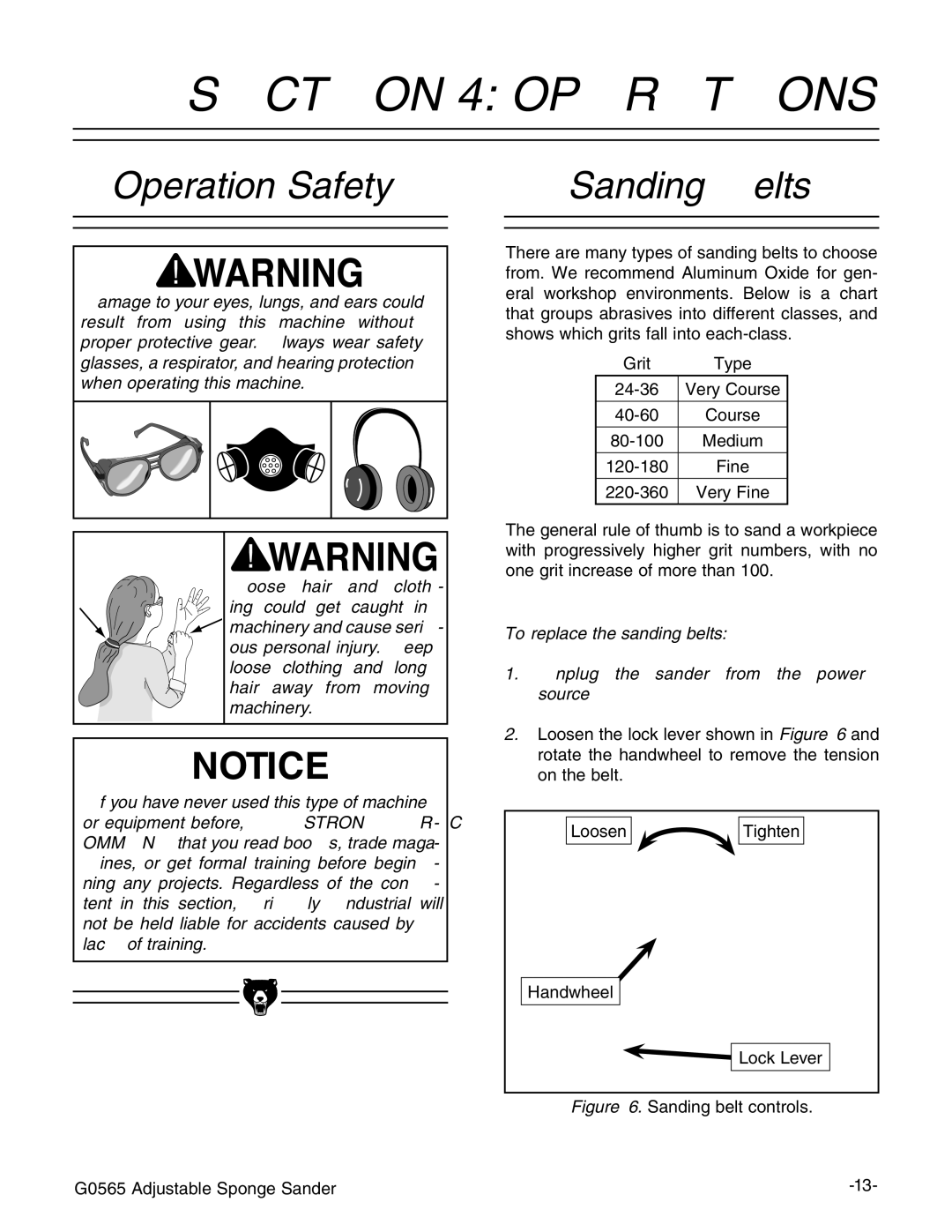

To replace the sanding belts:

1.Unplug the sander from the power source!

2.Loosen the lock lever shown in Figure 6 and rotate the handwheel to remove the tension on the belt.

Loosen | Tighten |

Handwheel |

|

| Lock Lever |

Figure 6. Sanding belt controls.

G0565 Adjustable Sponge Sander |