Belt Tensioning

Correct belt tension will insure that your sander functions properly. Too little tension will allow the belt to slip and may cause the sander to track erratically. Too much will cause the drive drum to creep on the drive shaft and possibly cause pre- mature bearing failure. It is impossible to describe ideal belt tension. A good rule of thumb is less tension is better than too much. If the belt sounds like a drum when plucked, your tension is proba- bly set too tight. If your belt does not track and slips under load, it is too loose. Use the following steps to adjust tension.

1.With belt installed and quick release lever engaged, loosen Hex Bolt, PN # 91 slightly. Figure 14. Note: Figure 14 is depicted with the belt removed for illustration purposes only. Normally steps

Figure 14.

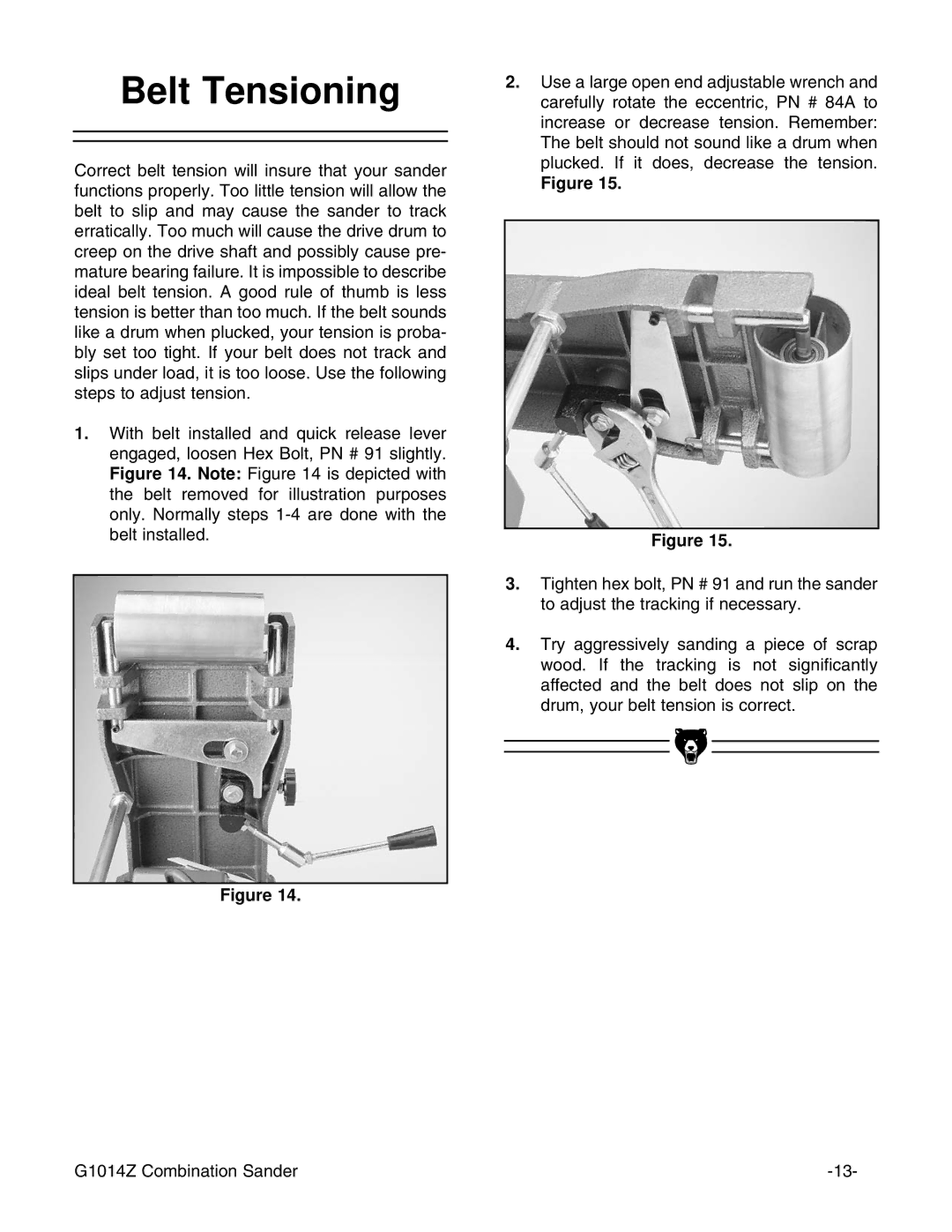

2.Use a large open end adjustable wrench and carefully rotate the eccentric, PN # 84A to increase or decrease tension. Remember: The belt should not sound like a drum when plucked. If it does, decrease the tension.

Figure 15.

Figure 15.

3.Tighten hex bolt, PN # 91 and run the sander to adjust the tracking if necessary.

4.Try aggressively sanding a piece of scrap wood. If the tracking is not significantly affected and the belt does not slip on the drum, your belt tension is correct.

G1014Z Combination Sander |