A

Figure 17. Feeler measures roller adjustment.

8.Move the feed speed control knob to the center neutral position.

9.Rotate the sprocket at the end of the infeed roller. The teeth at the bottom of the roller should contact the top of the block if the roller is properly adjusted. If the roller teeth will not clear the block, or if there is a gap between the block and the infeed roller, you will need to make adjustments.

10.If you need to adjust the roller up or down, loosen the lock nut and turn the setscrew to raise or lower the rollers. See Figure 18.

Figure 18. Adjusting roller height.

11.Follow the same procedure at the other end of the infeed roller and on both sides of the outfeed roller. Do not change the table height yet, the next sections will require the same settings.

12.Be sure to tighten the lock nut as soon as you have adjusted each roller to its proper height.

Spring Tension

Roller spring tension must be adjusted so that roller pressure is uniform. To adjust roller spring tension:

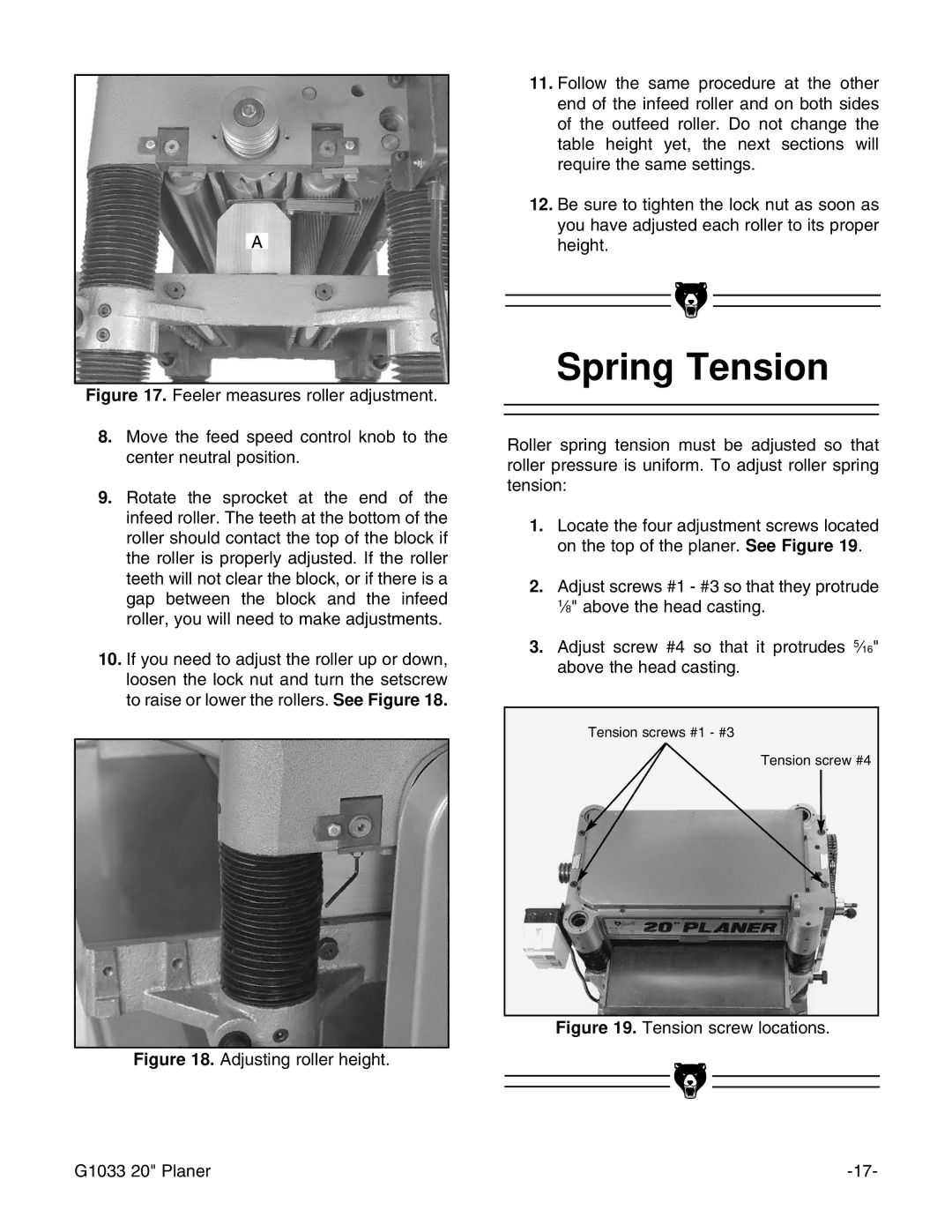

1.Locate the four adjustment screws located on the top of the planer. See Figure 19.

2.Adjust screws #1 - #3 so that they protrude 1Ú8" above the head casting.

3.Adjust screw #4 so that it protrudes 5Ú16" above the head casting.

Tension screws #1 - #3

Tension screw #4

Figure 19. Tension screw locations.

G1033 20" Planer |