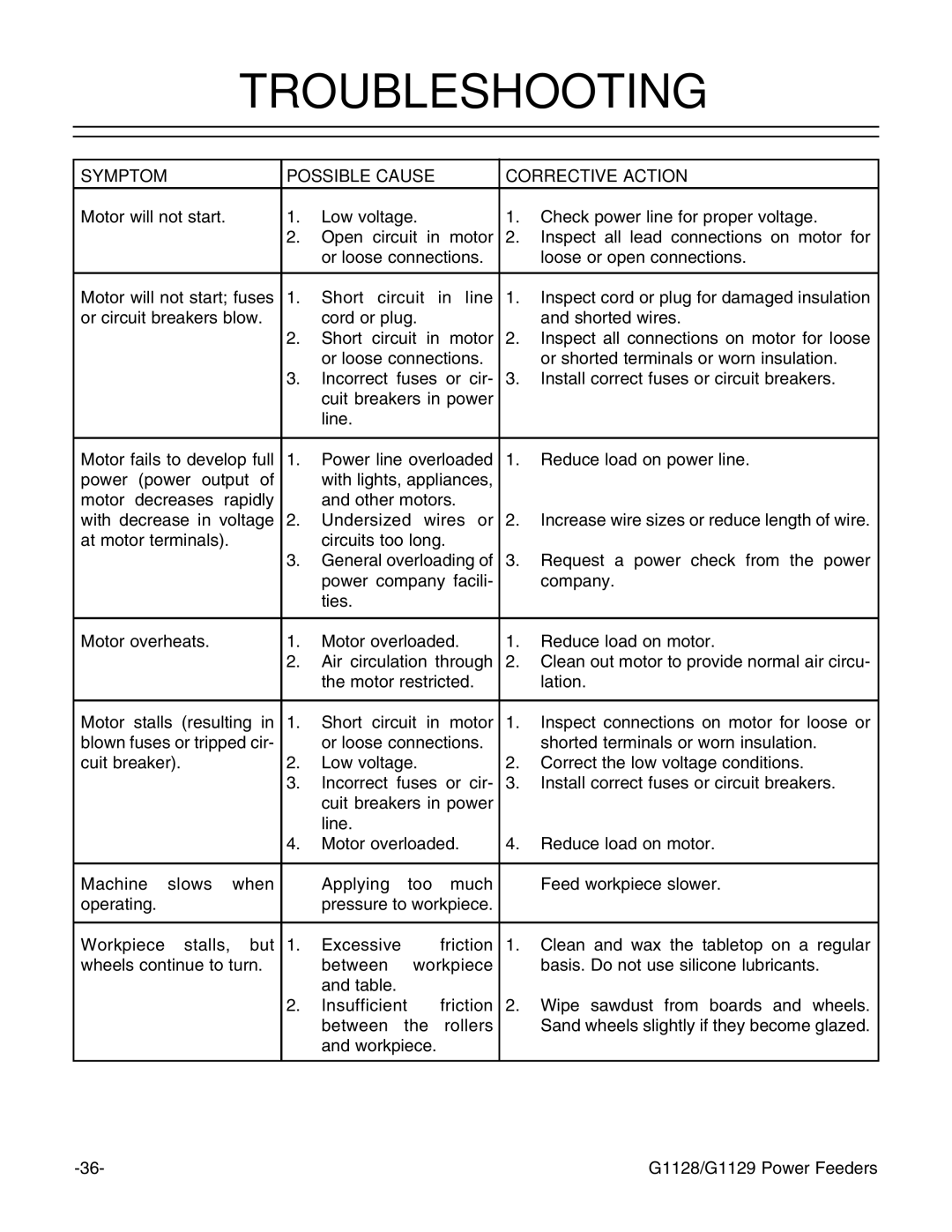

TROUBLESHOOTING

SYMPTOM |

|

| POSSIBLE CAUSE |

| CORRECTIVE ACTION | |||||

Motor will not start. |

| 1. | Low voltage. |

|

| 1. | Check power line for proper voltage. | |||

|

|

|

| 2. | Open circuit | in | motor | 2. | Inspect all lead connections on motor for | |

|

|

|

|

| or loose connections. |

| loose or open connections. | |||

|

|

|

|

|

| |||||

Motor will not start; fuses | 1. | Short circuit | in line | 1. | Inspect cord or plug for damaged insulation | |||||

or circuit breakers blow. |

| cord or plug. |

|

|

| and shorted wires. | ||||

|

|

|

| 2. | Short circuit | in | motor | 2. | Inspect all connections on motor for loose | |

|

|

|

|

| or loose connections. |

| or shorted terminals or worn insulation. | |||

|

|

|

| 3. | Incorrect fuses or cir- | 3. | Install correct fuses or circuit breakers. | |||

|

|

|

|

| cuit breakers in power |

|

| |||

|

|

|

|

| line. |

|

|

|

|

|

|

|

|

|

| ||||||

Motor fails to develop full | 1. | Power line overloaded | 1. | Reduce load on power line. | ||||||

power | (power output of |

| with lights, appliances, |

|

| |||||

motor | decreases rapidly |

| and other motors. |

|

| |||||

with decrease in voltage | 2. | Undersized wires or | 2. | Increase wire sizes or reduce length of wire. | ||||||

at motor terminals). |

|

| circuits too long. |

|

| |||||

|

|

|

| 3. | General overloading of | 3. | Request a power check from the power | |||

|

|

|

|

| power company facili- |

| company. | |||

|

|

|

|

| ties. |

|

|

|

|

|

|

|

|

|

|

| |||||

Motor overheats. |

| 1. | Motor overloaded. | 1. | Reduce load on motor. | |||||

|

|

|

| 2. | Air circulation through | 2. | Clean out motor to provide normal air circu- | |||

|

|

|

|

| the motor restricted. |

| lation. | |||

|

|

|

|

|

|

|

|

| ||

Motor | stalls | (resulting in | 1. | Short circuit | in | motor | 1. | Inspect connections on motor for loose or | ||

blown fuses or tripped cir- |

| or loose connections. |

| shorted terminals or worn insulation. | ||||||

cuit breaker). |

|

| 2. | Low voltage. |

|

| 2. | Correct the low voltage conditions. | ||

|

|

|

| 3. | Incorrect fuses or cir- | 3. | Install correct fuses or circuit breakers. | |||

|

|

|

|

| cuit breakers in power |

|

| |||

|

|

|

|

| line. |

|

|

|

|

|

|

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. | |||

|

|

|

|

|

|

|

| |||

Machine slows | when |

| Applying | too | much |

| Feed workpiece slower. | |||

operating. |

|

|

| pressure to workpiece. |

|

| ||||

|

|

|

|

|

|

|

|

|

| |

Workpiece | stalls, | but | 1. | Excessive |

|

| friction | 1. | Clean and wax the tabletop on a regular | |

wheels continue to turn. |

| between | workpiece |

| basis. Do not use silicone lubricants. | |||||

|

|

|

|

| and table. |

|

|

|

|

|

|

|

|

| 2. | Insufficient |

| friction | 2. | Wipe sawdust from boards and wheels. | |

|

|

|

|

| between | the | rollers |

| Sand wheels slightly if they become glazed. | |

|

|

|

|

| and workpiece. |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

G1128/G1129 Power Feeders |