SECTION 5: ADJUSTMENTS

Roller Placement

Your power feeder will operate best if the rollers are properly placed and their speed is correct for the job.

G1129: If you look at the rollers on the G1129, you will notice that the gap between the first and second rollers is larger than that between the second and third rollers. This arrangement allows you to place the rollers so the first wheel is slightly ahead of your cutting tool, while the middle and third wheels are behind. Thus, the rollers feed your workpiece into, through and past the cutting surface smoothly. This feature pro- vides consistent application of force without binding the cutting tool.

G1128: The G1128 does not have different sized gaps between the wheels. However, the first wheel must be placed slightly ahead of the cutter for the power feeder to work effectively.

To position the rollers correctly on the G1128 / G1129:

1.Raise the horizontal column so the rollers are just above the table.

2.Swing the motor and roller assembly so the rollers are just slightly away from the cutter, with the first roller slightly forward of the cut- ting region.

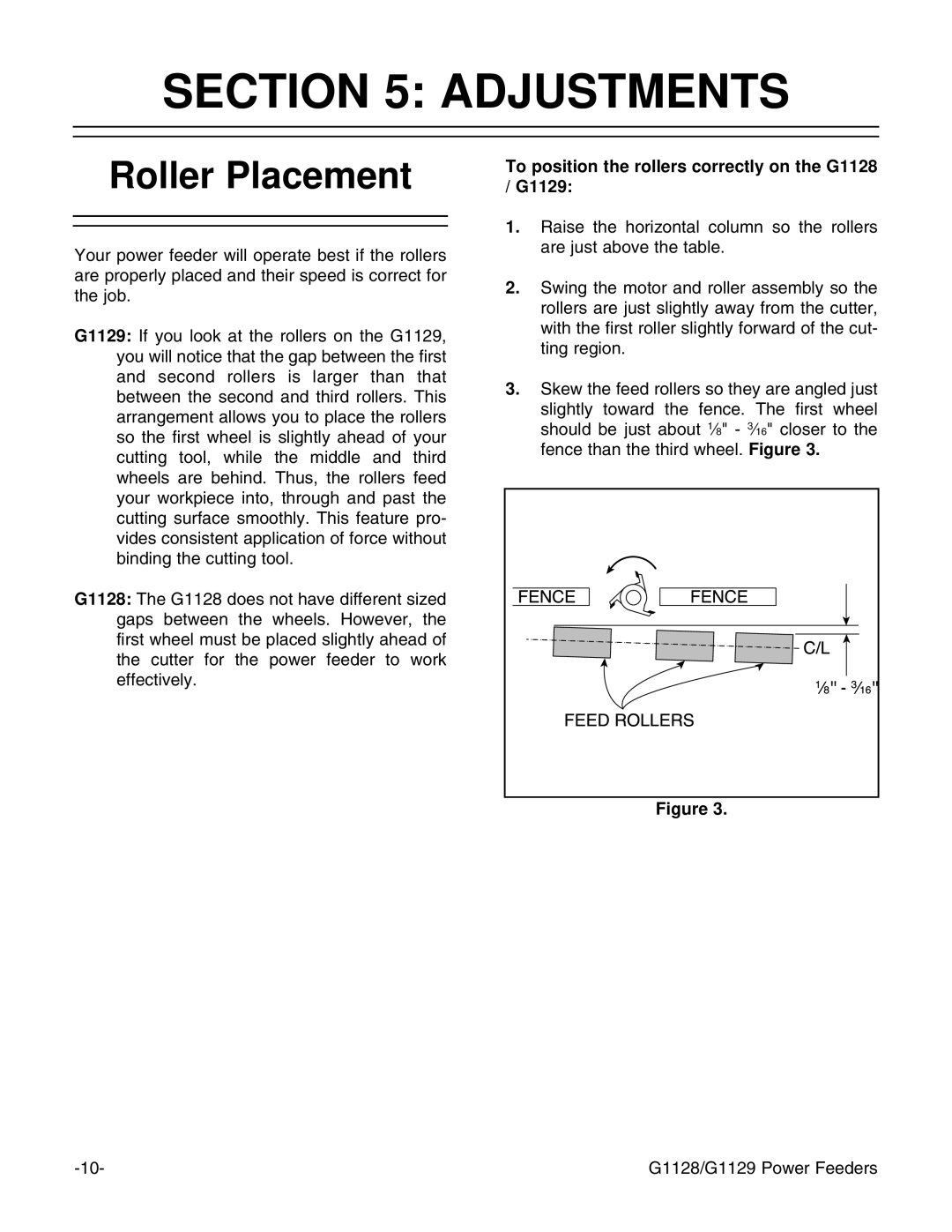

3.Skew the feed rollers so they are angled just slightly toward the fence. The first wheel should be just about 1⁄8" - 3⁄16" closer to the fence than the third wheel. Figure 3.

Figure 3.

G1128/G1129 Power Feeders |