Assembly | Safety | |

1. | Layout the parts and use Figure 1 to inven- | • SAFE STORAGE. Keep away from children |

| tory them. | and animals. Close the lid when not using the |

|

| parts washer. |

2. | Using a #2 screwdriver and a 10mm wrench, | • PLUG MODIFICATION HAZARD. To avoid |

| secure the legs to the storage shelf with eight | |

| electrical shock, this machine must be | |

| grounded. Never modify the included plug to | |

|

| connect it to a two prong receptacle or exten- |

3. | With the help of an assistant, place the tub | sion cord. |

| onto the legs and secure it in place with the |

|

| remaining 16 | • PREVENTING ELECTRICAL SHOCK. |

| washers, and | Only connect this parts washer to a prop- |

|

| erly grounded GFCI (Ground Fault Circuit |

4. | Use a 19mm wrench to install the spout and | Interrupt) receptacle. Test the GFCI recep- |

| tube onto the pump outlet (Figure 1). | tacle operation according to switch manufac- |

|

| turer recommended intervals. |

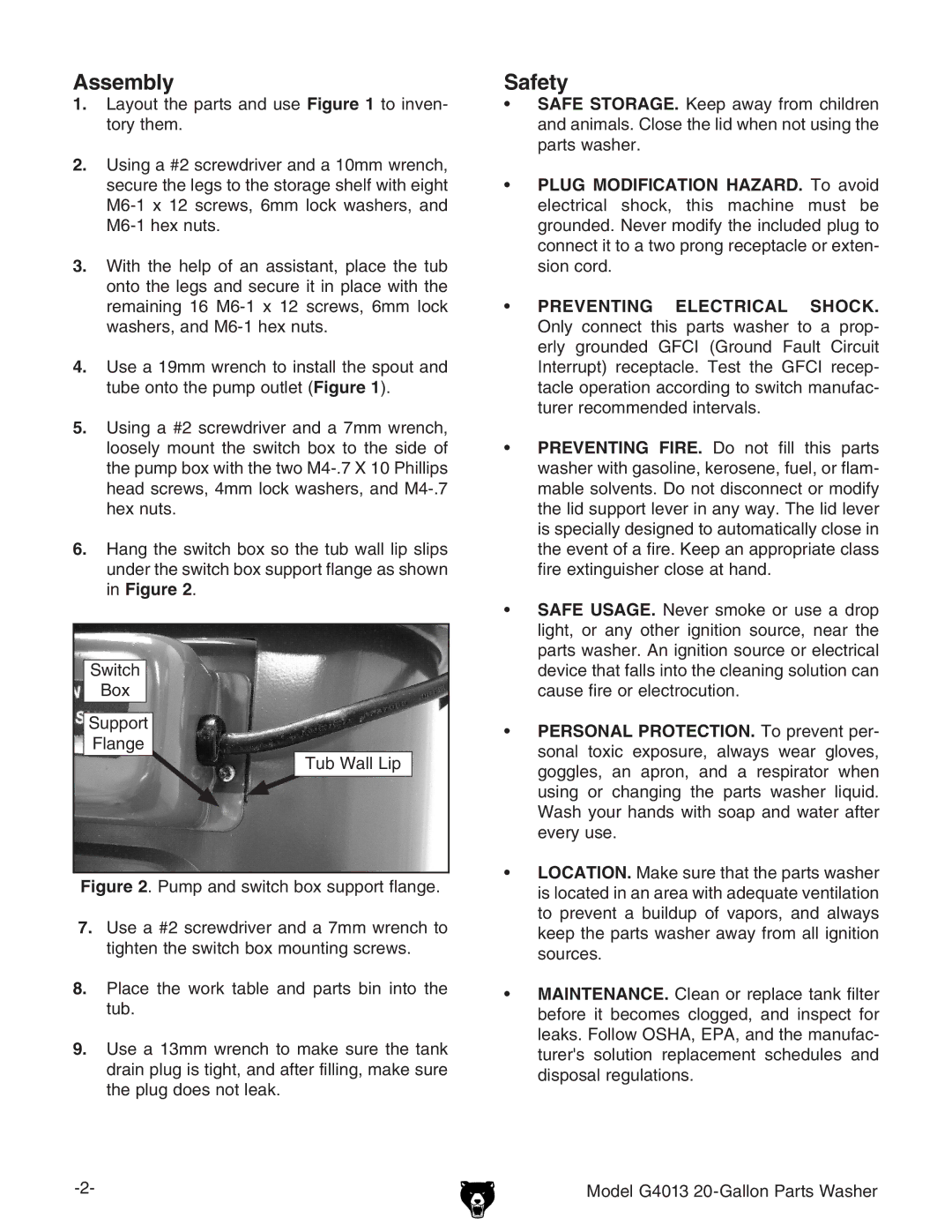

5.Using a #2 screwdriver and a 7mm wrench,

loosely mount the switch box to the side of | • PREVENTING FIRE. Do not fill this parts |

the pump box with the two | washer with gasoline, kerosene, fuel, or flam- |

head screws, 4mm lock washers, and | mable solvents. Do not disconnect or modify |

hex nuts. | the lid support lever in any way. The lid lever |

| is specially designed to automatically close in |

6. Hang the switch box so the tub wall lip slips | the event of a fire. Keep an appropriate class |

under the switch box support flange as shown | fire extinguisher close at hand. |

in Figure 2. |

|

| • SAFE USAGE. Never smoke or use a drop | ||

|

| light, or any other ignition source, near the | |

|

| parts washer. An ignition source or electrical | |

Switch |

| device that falls into the cleaning solution can | |

Box |

| cause fire or electrocution. | |

Support | • | PERSONAL PROTECTION. To prevent per- | |

Flange | |||

| sonal toxic exposure, always wear gloves, | ||

Tub Wall Lip |

| ||

| goggles, an apron, and a respirator when | ||

|

| ||

|

| using or changing the parts washer liquid. | |

|

| Wash your hands with soap and water after | |

|

| every use. | |

Figure 2. Pump and switch box support flange. | • LOCATION. Make sure that the parts washer | ||

| is located in an area with adequate ventilation | ||

|

| ||

7. Use a #2 screwdriver and a 7mm wrench to |

| to prevent a buildup of vapors, and always | |

| keep the parts washer away from all ignition | ||

tighten the switch box mounting screws. |

| ||

| sources. | ||

|

| ||

8. Place the work table and parts bin into the | • | MAINTENANCE. Clean or replace tank filter | |

tub. | |||

| before it becomes clogged, and inspect for | ||

|

| ||

9. Use a 13mm wrench to make sure the tank |

| leaks. Follow OSHA, EPA, and the manufac- | |

| turer's solution replacement schedules and | ||

drain plug is tight, and after filling, make sure |

| ||

| disposal regulations. | ||

the plug does not leak. |

| ||

|

|

Model G4013 |