Wheel Dressing

Dressing is performed on the face of the grinding wheel to sharpen the abrasives or to remove material which has imbedded in the surface. Dressing also makes the circumference of the wheel true to its centerpoint, thus insuring good grinding results. Wheels should always be dressed when first installed on the machine, and also periodically as the wheel is used. The fre- quency will depend upon the types of materials being ground, and the severity of the grinding operations. A wheel which will not balance prop- erly may need to be dressed to true first to assure concentricity.

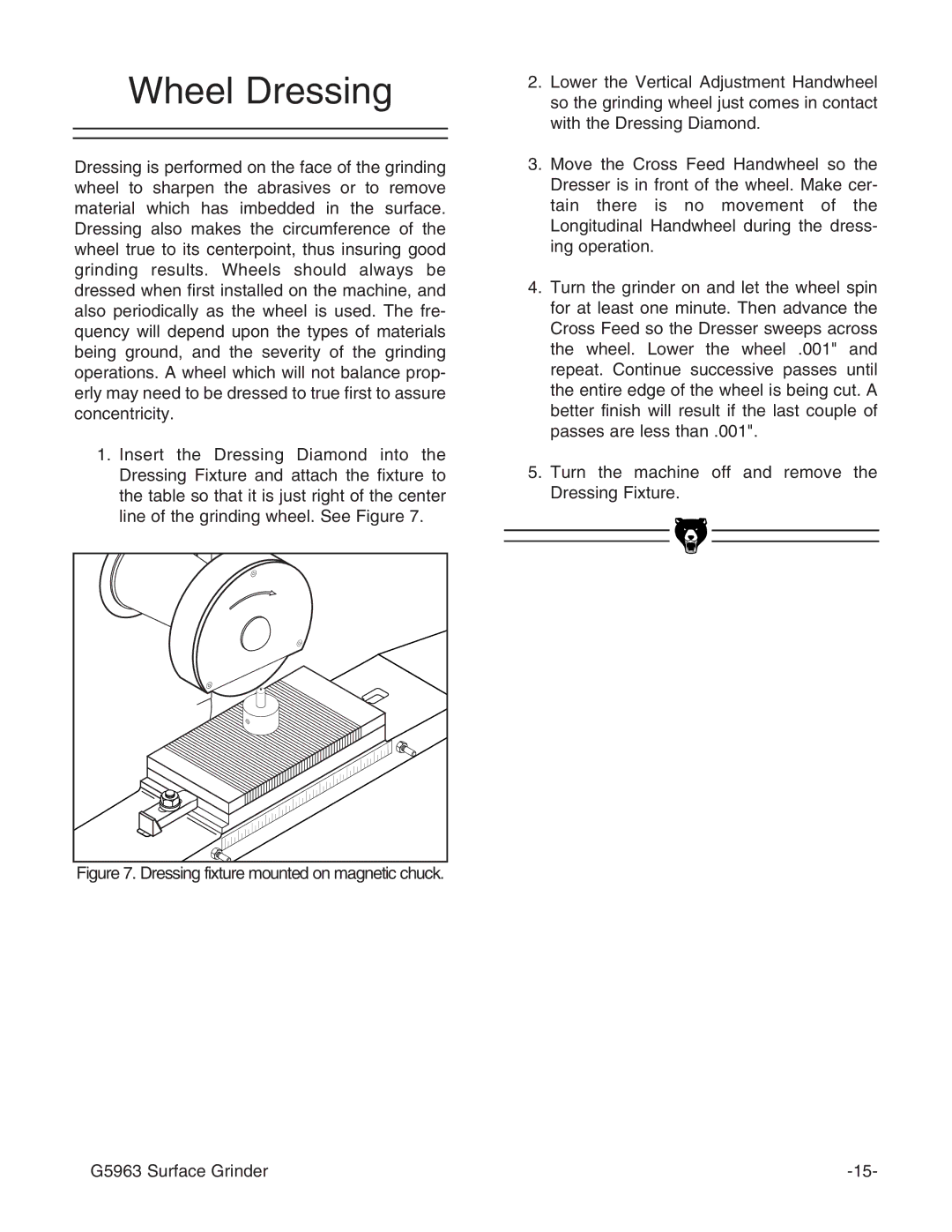

1.Insert the Dressing Diamond into the Dressing Fixture and attach the fixture to the table so that it is just right of the center line of the grinding wheel. See Figure 7.

Figure 7. Dressing fixture mounted on magnetic chuck.

2.Lower the Vertical Adjustment Handwheel so the grinding wheel just comes in contact with the Dressing Diamond.

3.Move the Cross Feed Handwheel so the Dresser is in front of the wheel. Make cer- tain there is no movement of the Longitudinal Handwheel during the dress- ing operation.

4.Turn the grinder on and let the wheel spin for at least one minute. Then advance the Cross Feed so the Dresser sweeps across the wheel. Lower the wheel .001" and repeat. Continue successive passes until the entire edge of the wheel is being cut. A better finish will result if the last couple of passes are less than .001".

5.Turn the machine off and remove the Dressing Fixture.

G5963 Surface Grinder |