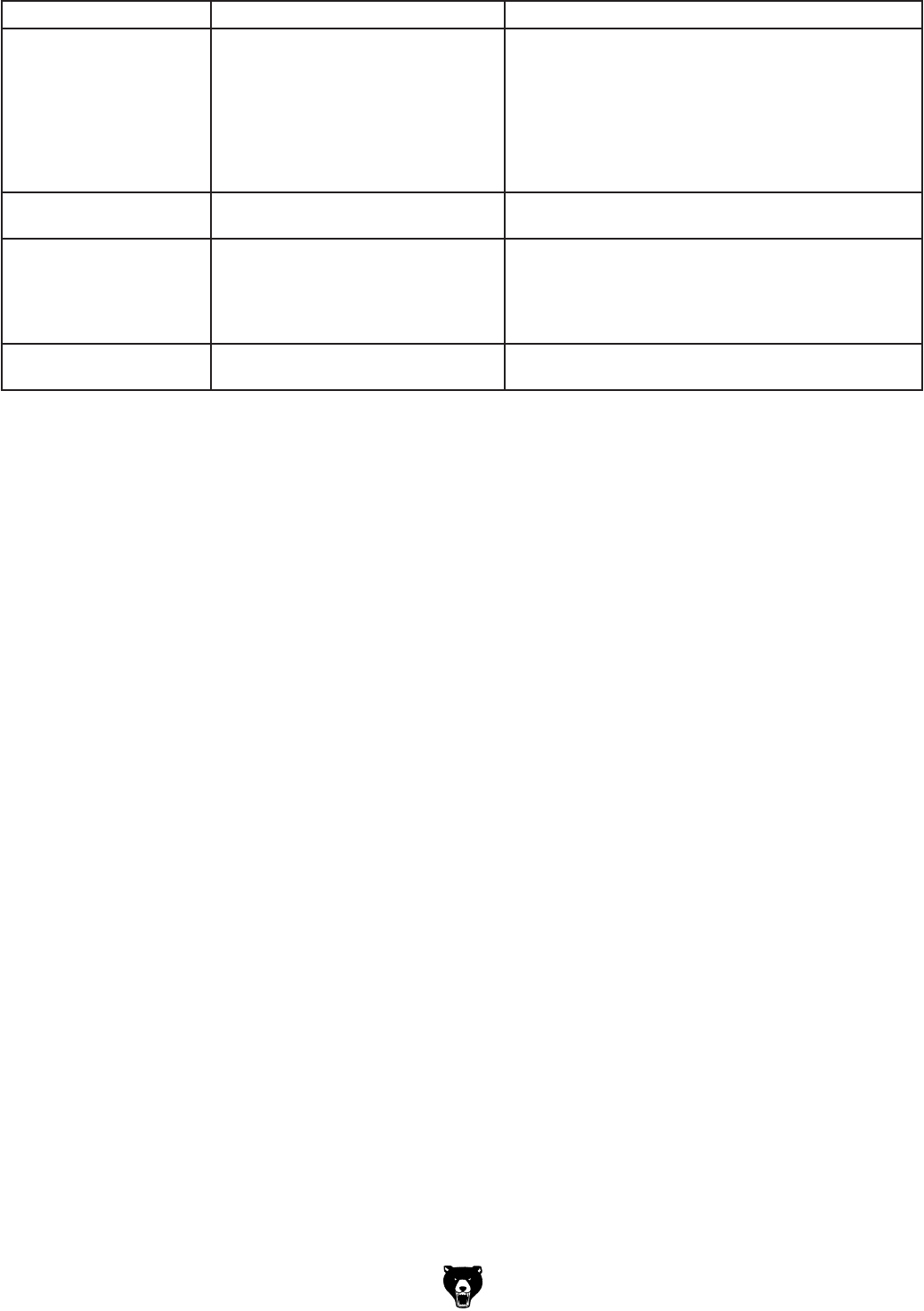

Model g8688 (Mfg. 3/09+) -33-

Model g8688 (Mfg. 3/09+) -33-syMpTOM pOssIbLE cAusE cOrrEcTIvE AcTION

Carriage hard to move. 1. Carriage lock is tightened down.

2. Chips have loaded up on bedways.

3. Bedways are dry and in need of

lubrication.

4. longitudi nal stops are interfering.

5. gibs are too tight.

1. Check to make sure table locks are fully released.

2. Frequently c lean away chips that load up dur ing

turning operations.

3. lubricate bedways and handles.

4. Check to make sure that sto ps are floating and not

hitting the center stop.

5. loosen gib screw(s) slightly.

gear change levers will not

shift into position.

1. gears not aligned in headstoc k. 1. rotate spindle by hand until gear falls into place.

loud, repetitious noise

coming from machine.

1. gears not aligned in headstoc k or

no backlash.

2. Broken gear or bad bearing .

3. Workpiece is hitting stationary

object.

1. adjust gears and establish backlash.

2. replace broken gear or b earing.

3. Stop lathe immediately an d correct interference

problem.

tailstock quill will not feed

out of tailstock.

1. Quill lock knob is tightened down. 1. turn knob counterclockwise.