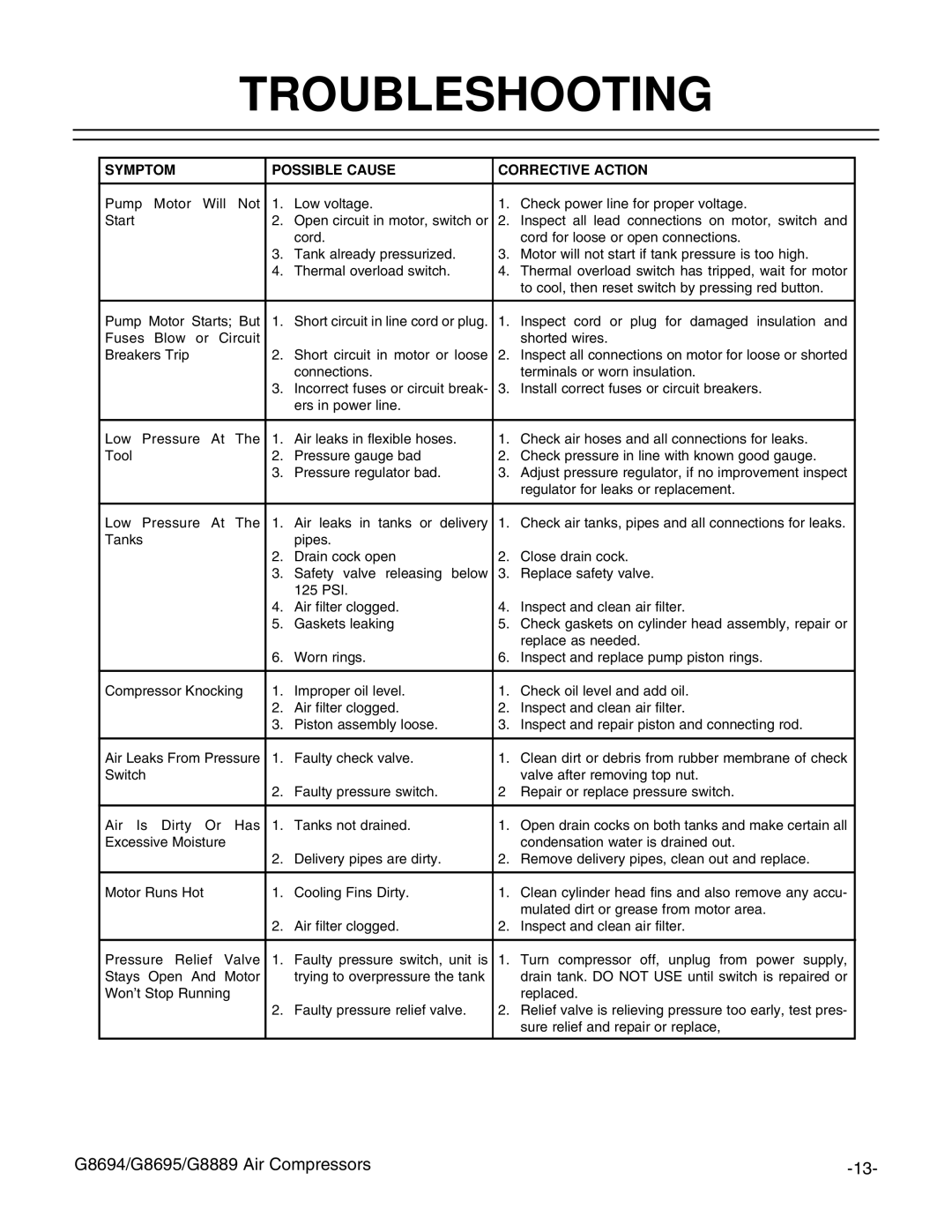

TROUBLESHOOTING

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SYMPTOM |

|

|

|

|

|

| POSSIBLE CAUSE |

|

| CORRECTIVE ACTION |

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Pump | Motor | Will | Not |

|

| 1. | Low voltage. |

|

| 1. | Check power line for proper voltage. |

| |||

| Start |

|

|

|

|

|

|

|

| 2. | Open circuit in motor, switch or |

|

| 2. | Inspect all lead connections on motor, switch and |

|

|

|

|

|

|

|

|

|

|

|

| cord. |

|

|

| cord for loose or open connections. |

|

|

|

|

|

|

|

|

|

|

| 3. | Tank already pressurized. |

|

| 3. | Motor will not start if tank pressure is too high. |

|

|

|

|

|

|

|

|

|

|

| 4. | Thermal overload switch. |

|

| 4. | Thermal overload switch has tripped, wait for motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| to cool, then reset switch by pressing red button. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Pump |

| Motor | Starts; | But |

|

| 1. | Short circuit in line cord or plug. |

|

| 1. | Inspect cord or plug for damaged insulation and |

| ||

| Fuses | Blow | or |

| Circuit |

|

|

|

|

|

|

| shorted wires. |

| ||

| Breakers Trip |

|

|

|

|

|

| 2. | Short circuit in motor or loose |

|

| 2. | Inspect all connections on motor for loose or shorted |

| ||

|

|

|

|

|

|

|

|

|

|

| connections. |

|

|

| terminals or worn insulation. |

|

|

|

|

|

|

|

|

|

|

| 3. | Incorrect fuses or circuit break- |

|

| 3. | Install correct fuses or circuit breakers. |

|

|

|

|

|

|

|

|

|

|

|

| ers in power line. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Low | Pressure | At | The |

|

| 1. | Air leaks in flexible hoses. |

|

| 1. | Check air hoses and all connections for leaks. |

| |||

| Tool |

|

|

|

|

|

|

|

| 2. | Pressure gauge bad |

|

| 2. | Check pressure in line with known good gauge. |

|

|

|

|

|

|

|

|

|

|

| 3. | Pressure regulator bad. |

|

| 3. | Adjust pressure regulator, if no improvement inspect |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| regulator for leaks or replacement. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Low | Pressure | At | The |

|

| 1. | Air leaks in tanks or delivery |

|

| 1. | Check air tanks, pipes and all connections for leaks. |

| |||

| Tanks |

|

|

|

|

|

|

|

| pipes. |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| 2. | Drain cock open |

|

| 2. | Close drain cock. |

|

|

|

|

|

|

|

|

|

|

| 3. | Safety valve releasing below |

|

| 3. | Replace safety valve. |

|

|

|

|

|

|

|

|

|

|

|

| 125 PSI. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4. | Air filter clogged. |

|

| 4. | Inspect and clean air filter. |

|

|

|

|

|

|

|

|

|

|

| 5. | Gaskets leaking |

|

| 5. | Check gaskets on cylinder head assembly, repair or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| replace as needed. |

|

|

|

|

|

|

|

|

|

|

| 6. | Worn rings. |

|

| 6. | Inspect and replace pump piston rings. |

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| Compressor Knocking |

|

| 1. | Improper oil level. |

|

| 1. | Check oil level and add oil. |

| ||||||

|

|

|

|

|

|

|

|

|

| 2. | Air filter clogged. |

|

| 2. | Inspect and clean air filter. |

|

|

|

|

|

|

|

|

|

|

| 3. | Piston assembly loose. |

|

| 3. | Inspect and repair piston and connecting rod. |

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| Air Leaks From Pressure |

|

| 1. | Faulty check valve. |

|

| 1. | Clean dirt or debris from rubber membrane of check |

| ||||||

| Switch |

|

|

|

|

|

|

|

|

|

|

|

| valve after removing top nut. |

| |

|

|

|

|

|

|

|

|

|

| 2. | Faulty pressure switch. |

|

| 2 | Repair or replace pressure switch. |

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| Air Is Dirty Or Has |

|

| 1. | Tanks not drained. |

|

| 1. | Open drain cocks on both tanks and make certain all |

| ||||||

| Excessive Moisture |

|

|

|

|

|

|

|

| condensation water is drained out. |

| |||||

|

|

|

|

|

|

|

|

|

| 2. | Delivery pipes are dirty. |

|

| 2. | Remove delivery pipes, clean out and replace. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Motor Runs Hot |

|

|

|

|

| 1. | Cooling Fins Dirty. |

|

| 1. | Clean cylinder head fins and also remove any accu- |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| mulated dirt or grease from motor area. |

|

|

|

|

|

|

|

|

|

|

| 2. | Air filter clogged. |

|

| 2. | Inspect and clean air filter. |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

| Pressure Relief | Valve |

|

| 1. | Faulty pressure switch, unit is |

|

| 1. | Turn compressor off, unplug from power supply, |

| |||||

| Stays |

| Open | And | Motor |

|

|

| trying to overpressure the tank |

|

|

| drain tank. DO NOT USE until switch is repaired or |

| ||

| Won’t Stop Running |

|

|

|

|

|

|

|

| replaced. |

| |||||

|

|

|

|

|

|

|

|

|

| 2. | Faulty pressure relief valve. |

|

| 2. | Relief valve is relieving pressure too early, test pres- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| sure relief and repair or replace, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G8694/G8695/G8889 Air Compressors |