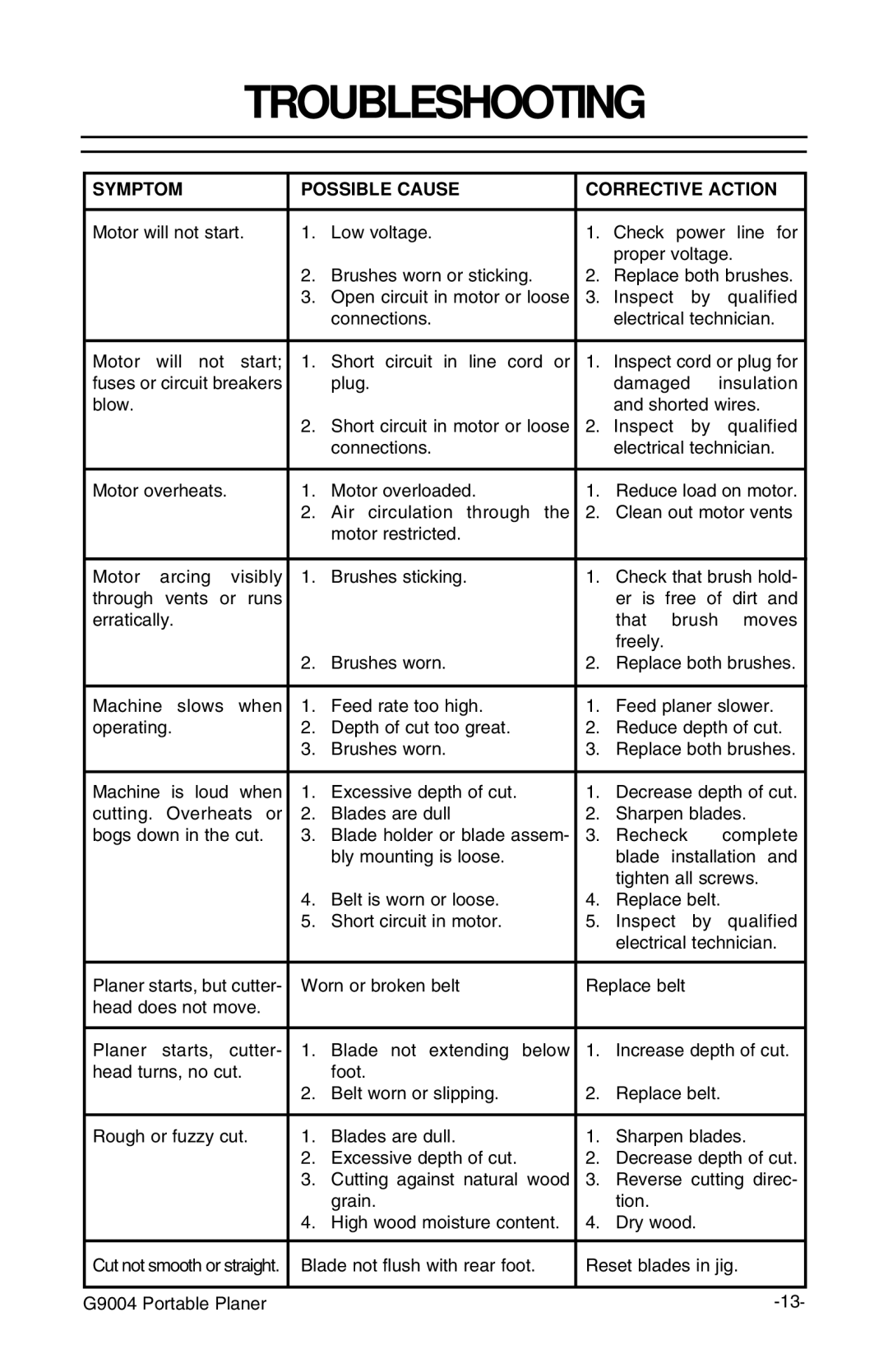

TROUBLESHOOTING

SYMPTOM |

|

| POSSIBLE CAUSE | CORRECTIVE ACTION | ||||||

|

|

|

|

|

|

| ||||

Motor will not start. | 1. | Low voltage. | 1. | Check |

| power line for | ||||

|

|

|

|

|

|

| proper voltage. | |||

|

|

|

| 2. | Brushes worn or sticking. | 2. | Replace both brushes. | |||

|

|

|

| 3. | Open circuit in motor or loose | 3. | Inspect | by | qualified | |

|

|

|

|

| connections. |

| electrical technician. | |||

|

|

|

|

|

|

|

| |||

Motor | will | not | start; | 1. | Short circuit in line cord or | 1. | Inspect cord or plug for | |||

fuses or circuit breakers |

| plug. |

| damaged | insulation | |||||

blow. |

|

|

|

|

|

| and shorted wires. | |||

|

|

|

| 2. | Short circuit in motor or loose | 2. | Inspect | by | qualified | |

|

|

|

|

| connections. |

| electrical technician. | |||

|

|

|

|

|

| |||||

Motor overheats. |

| 1. | Motor overloaded. | 1. | Reduce load on motor. | |||||

|

|

|

| 2. | Air circulation through the | 2. | Clean out motor vents | |||

|

|

|

|

| motor restricted. |

|

|

|

|

|

|

|

|

|

|

|

| ||||

Motor | arcing | visibly | 1. | Brushes sticking. | 1. | Check that brush hold- | ||||

through | vents or runs |

|

|

| er is free of dirt and | |||||

erratically. |

|

|

|

|

| that | brush | moves | ||

|

|

|

|

|

|

| freely. |

|

|

|

|

|

|

| 2. | Brushes worn. | 2. | Replace both brushes. | |||

|

|

|

|

|

| |||||

Machine slows | when | 1. | Feed rate too high. | 1. | Feed planer slower. | |||||

operating. |

|

| 2. | Depth of cut too great. | 2. | Reduce depth of cut. | ||||

|

|

|

| 3. | Brushes worn. | 3. | Replace both brushes. | |||

|

|

|

|

|

|

| ||||

Machine is | loud | when | 1. | Excessive depth of cut. | 1. | Decrease depth of cut. | ||||

cutting. | Overheats or | 2. | Blades are dull | 2. | Sharpen blades. | |||||

bogs down in the cut. | 3. | Blade holder or blade assem- | 3. | Recheck | complete | |||||

|

|

|

|

| bly mounting is loose. |

| blade | installation and | ||

|

|

|

|

|

|

| tighten all screws. | |||

|

|

|

| 4. | Belt is worn or loose. | 4. | Replace belt. | |||

|

|

|

| 5. | Short circuit in motor. | 5. | Inspect | by | qualified | |

|

|

|

|

|

|

| electrical technician. | |||

|

|

|

| |||||||

Planer starts, but cutter- | Worn or broken belt | Replace belt |

| |||||||

head does not move. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| ||||

Planer | starts, | cutter- | 1. | Blade not extending below | 1. | Increase depth of cut. | ||||

head turns, no cut. |

| foot. |

|

|

|

|

| |||

|

|

|

| 2. | Belt worn or slipping. | 2. | Replace belt. | |||

|

|

|

|

| ||||||

Rough or fuzzy cut. | 1. | Blades are dull. | 1. | Sharpen blades. | ||||||

|

|

|

| 2. | Excessive depth of cut. | 2. | Decrease depth of cut. | |||

|

|

|

| 3. | Cutting against natural wood | 3. | Reverse cutting direc- | |||

|

|

|

|

| grain. |

| tion. |

|

|

|

|

|

|

| 4. | High wood moisture content. | 4. | Dry wood. |

| ||

|

|

| ||||||||

Cut not smooth or straight. | Blade not flush with rear foot. | Reset blades in jig. | ||||||||

|

|

|

|

|

|

|

|

|

|

|

G9004 Portable Planer |