To make five evenly spaced holes:

1.Use the handwheel to rotate the rotary table to the zero mark on the table scale, then tighten both table locks.

Note: Make sure the handwheel and vernier scales also read zero.

2.Drill the first hole.

3.Unlock the table, then turn the handwheel 18 full turns which will rotate the rotary table to 72° as displayed on the table scale.

Note: Be careful not to pass the zero mark on the last turn. If you go past the zero mark, reverse the handwheel one full turn, then try again. This will eliminate any backlash error that occurs when reversing handwheel direc- tion.

4.Lock the table in place and drill the hole.

5.Repeat Steps

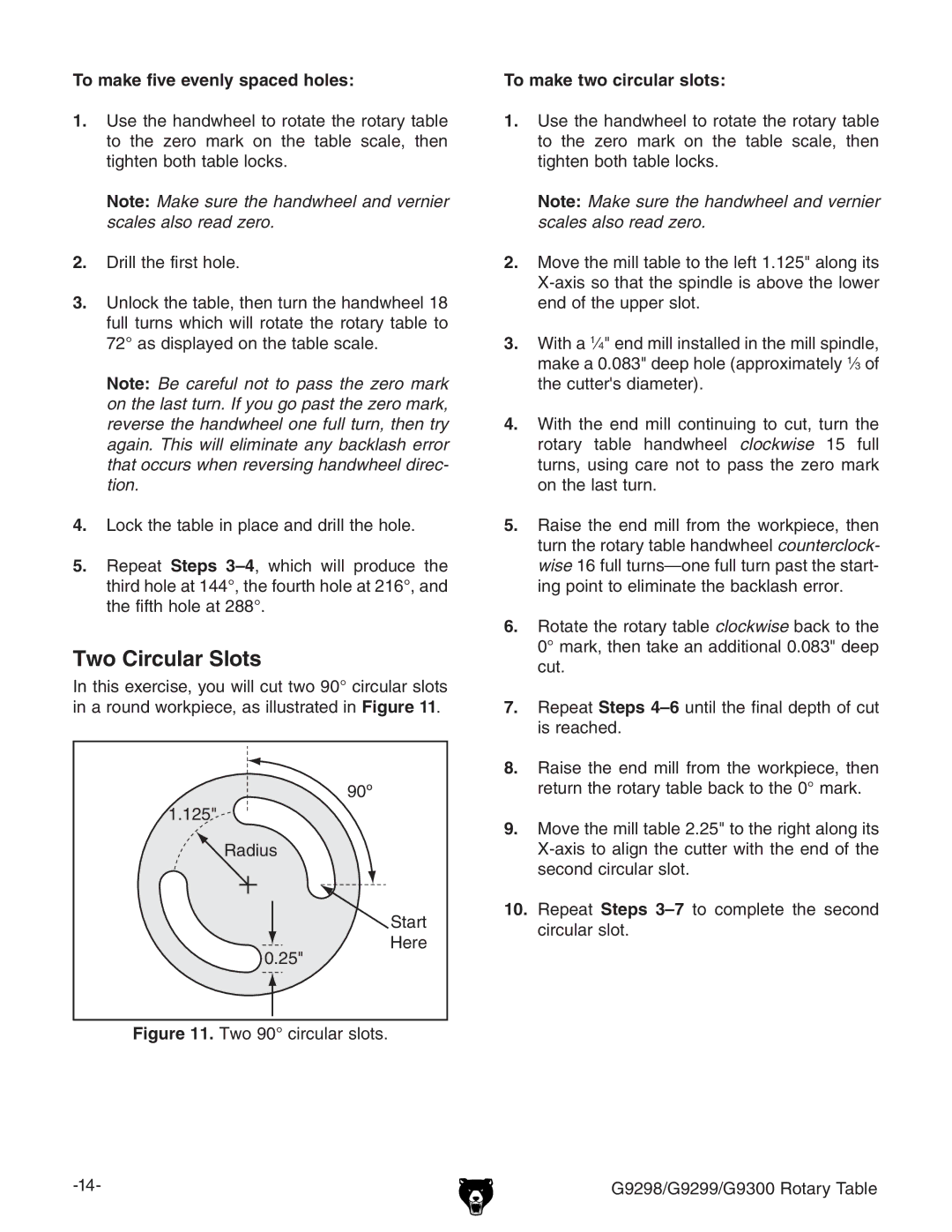

Two Circular Slots

In this exercise, you will cut two 90° circular slots in a round workpiece, as illustrated in Figure 11.

To make two circular slots:

1. | Use the handwheel to rotate the rotary table |

| to the zero mark on the table scale, then |

| tighten both table locks. |

| Note: Make sure the handwheel and vernier |

| scales also read zero. |

2. | Move the mill table to the left 1.125" along its |

| |

| end of the upper slot. |

3. | With a 1⁄4" end mill installed in the mill spindle, |

| make a 0.083" deep hole (approximately 1⁄3 of |

| the cutter's diameter). |

4. | With the end mill continuing to cut, turn the |

| rotary table handwheel clockwise 15 full |

| turns, using care not to pass the zero mark |

| on the last turn. |

5. | Raise the end mill from the workpiece, then |

| turn the rotary table handwheel counterclock- |

| wise 16 full |

| ing point to eliminate the backlash error. |

6. | Rotate the rotary table clockwise back to the |

| 0° mark, then take an additional 0.083" deep |

| cut. |

7. | Repeat Steps |

| is reached. |

8. | Raise the end mill from the workpiece, then |

1.125"

Radius

0.25"

90º

![]() Start Here

Start Here

| return the rotary table back to the 0° mark. |

9. | Move the mill table 2.25" to the right along its |

| |

| second circular slot. |

10. | Repeat Steps |

| circular slot. |