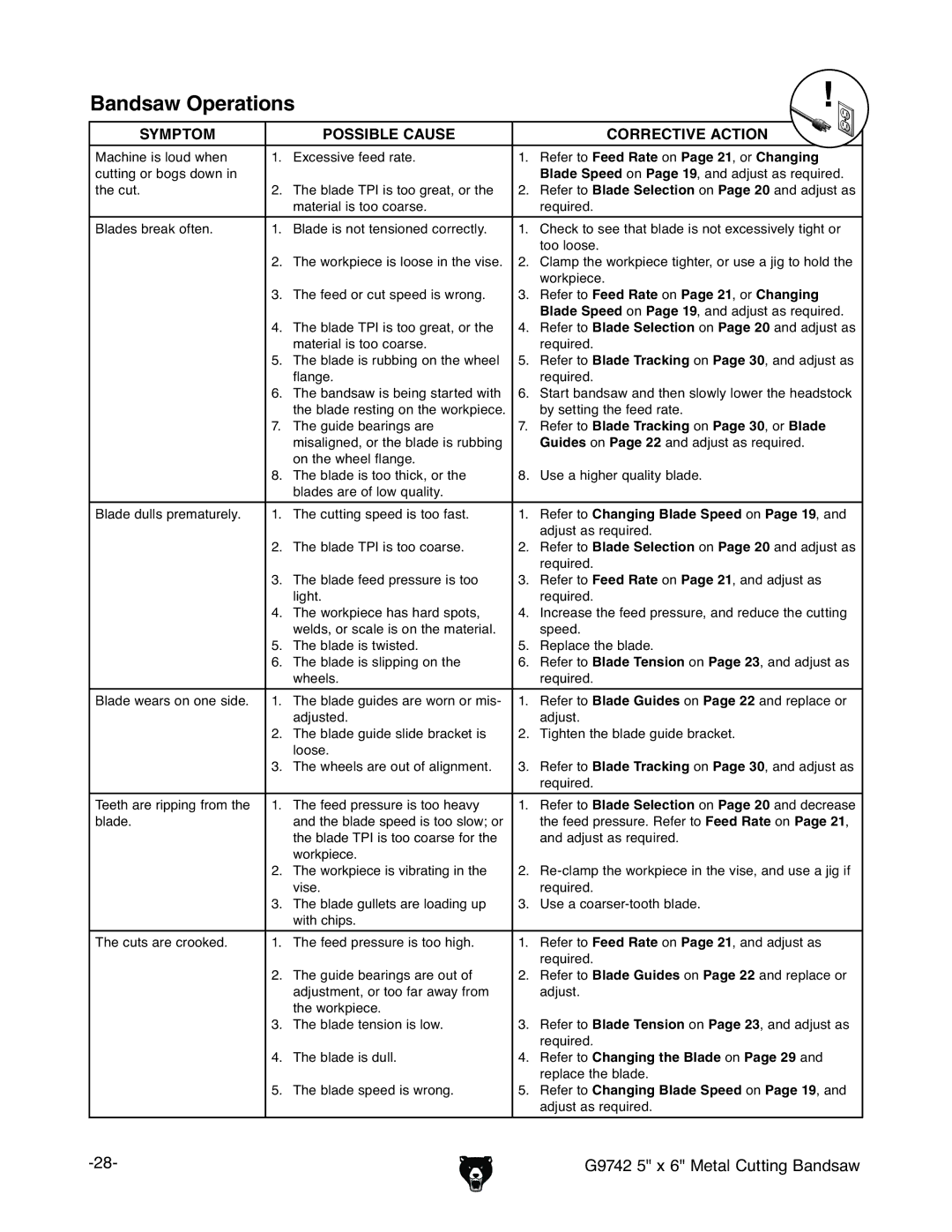

Bandsaw Operations

SYMPTOM |

| POSSIBLE CAUSE |

| CORRECTIVE ACTION |

Machine is loud when | 1. | Excessive feed rate. | 1. | Refer to Feed Rate on Page 21, or Changing |

cutting or bogs down in |

|

|

| Blade Speed on Page 19, and adjust as required. |

the cut. | 2. The blade TPI is too great, or the | 2. Refer to Blade Selection on Page 20 and adjust as | ||

|

| material is too coarse. |

| required. |

|

|

|

|

|

Blades break often. | 1. | Blade is not tensioned correctly. | 1. | Check to see that blade is not excessively tight or |

|

|

|

| too loose. |

2.The workpiece is loose in the vise. 2. Clamp the workpiece tighter, or use a jig to hold the

workpiece.

| 3. | The feed or cut speed is wrong. | 3. | Refer to Feed Rate on Page 21, or Changing |

|

|

|

| Blade Speed on Page 19, and adjust as required. |

| 4. | The blade TPI is too great, or the | 4. | Refer to Blade Selection on Page 20 and adjust as |

|

| material is too coarse. |

| required. |

| 5. | The blade is rubbing on the wheel | 5. | Refer to Blade Tracking on Page 30, and adjust as |

|

| flange. |

| required. |

| 6. | The bandsaw is being started with | 6. | Start bandsaw and then slowly lower the headstock |

|

| the blade resting on the workpiece. |

| by setting the feed rate. |

| 7. | The guide bearings are | 7. | Refer to Blade Tracking on Page 30, or Blade |

|

| misaligned, or the blade is rubbing |

| Guides on Page 22 and adjust as required. |

|

| on the wheel flange. |

|

|

| 8. | The blade is too thick, or the | 8. | Use a higher quality blade. |

|

| blades are of low quality. |

|

|

|

|

|

|

|

Blade dulls prematurely. | 1. | The cutting speed is too fast. | 1. | Refer to Changing Blade Speed on Page 19, and |

|

|

|

| adjust as required. |

| 2. | The blade TPI is too coarse. | 2. | Refer to Blade Selection on Page 20 and adjust as |

|

|

|

| required. |

| 3. | The blade feed pressure is too | 3. | Refer to Feed Rate on Page 21, and adjust as |

|

| light. |

| required. |

| 4. | The workpiece has hard spots, | 4. | Increase the feed pressure, and reduce the cutting |

|

| welds, or scale is on the material. |

| speed. |

| 5. | The blade is twisted. | 5. | Replace the blade. |

| 6. | The blade is slipping on the | 6. | Refer to Blade Tension on Page 23, and adjust as |

|

| wheels. |

| required. |

|

|

|

|

|

Blade wears on one side. | 1. | The blade guides are worn or mis- | 1. | Refer to Blade Guides on Page 22 and replace or |

|

| adjusted. |

| adjust. |

| 2. | The blade guide slide bracket is | 2. | Tighten the blade guide bracket. |

|

| loose. |

|

|

| 3. | The wheels are out of alignment. | 3. | Refer to Blade Tracking on Page 30, and adjust as |

|

|

|

| required. |

|

|

|

|

|

Teeth are ripping from the | 1. | The feed pressure is too heavy | 1. | Refer to Blade Selection on Page 20 and decrease |

blade. |

| and the blade speed is too slow; or |

| the feed pressure. Refer to Feed Rate on Page 21, |

|

| the blade TPI is too coarse for the |

| and adjust as required. |

|

| workpiece. |

|

|

| 2. | The workpiece is vibrating in the | 2. | |

|

| vise. |

| required. |

| 3. | The blade gullets are loading up | 3. | Use a |

|

| with chips. |

|

|

|

|

|

|

|

The cuts are crooked. | 1. | The feed pressure is too high. | 1. | Refer to Feed Rate on Page 21, and adjust as |

|

|

|

| required. |

| 2. | The guide bearings are out of | 2. | Refer to Blade Guides on Page 22 and replace or |

|

| adjustment, or too far away from |

| adjust. |

|

| the workpiece. |

|

|

| 3. | The blade tension is low. | 3. | Refer to Blade Tension on Page 23, and adjust as |

|

|

|

| required. |

| 4. | The blade is dull. | 4. | Refer to Changing the Blade on Page 29 and |

|

|

|

| replace the blade. |

| 5. | The blade speed is wrong. | 5. | Refer to Changing Blade Speed on Page 19, and |

|

|

|

| adjust as required. |

G9742 5" x 6" Metal Cutting Bandsaw |