Lash Adjustment

The Model G9986 features a lash adjustment set screw for the quill. Quill lash is the freeplay in the quill as it moves up and down. Having too much lash in the quill makes the quill prone to vibration and runout. Setting the quill lash too tight makes it difficult to move the quill up and down. The goal is to find the "sweet spot" where there is the perfect balance between ease of movement and restricted quill lash.

Tools Needed | Qty |

Hex Wrench 3mm | .............................................. 1 |

Wrench 10mm | 1 |

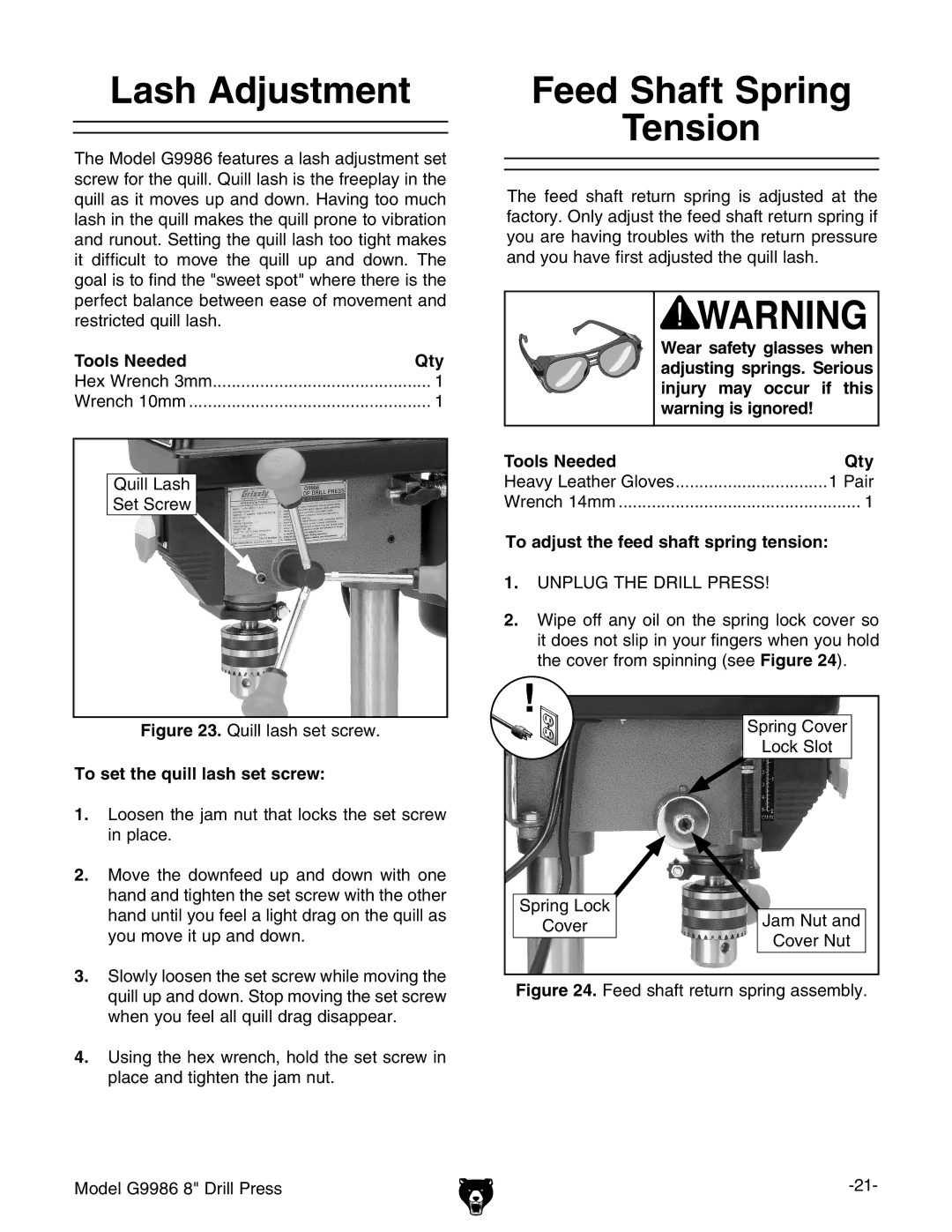

Quill Lash

Set Screw

Figure 23. Quill lash set screw.

To set the quill lash set screw:

1.Loosen the jam nut that locks the set screw in place.

2.Move the downfeed up and down with one hand and tighten the set screw with the other hand until you feel a light drag on the quill as you move it up and down.

3.Slowly loosen the set screw while moving the quill up and down. Stop moving the set screw when you feel all quill drag disappear.

4.Using the hex wrench, hold the set screw in

place and tighten the jam nut.

Feed Shaft Spring

Tension

The feed shaft return spring is adjusted at the factory. Only adjust the feed shaft return spring if you are having troubles with the return pressure and you have first adjusted the quill lash.

Wear safety glasses when | |

adjusting springs. Serious | |

injury may occur | if this |

warning is ignored! |

|

Tools Needed | Qty |

Heavy Leather Gloves | 1 Pair |

Wrench 14mm | 1 |

To adjust the feed shaft spring tension: | |

1.UNPLUG THE DRILL PRESS!

2.Wipe off any oil on the spring lock cover so it does not slip in your fingers when you hold the cover from spinning (see Figure 24).

| Spring Cover | |

| Lock Slot | |

Spring Lock | Jam Nut and | |

Cover | ||

Cover Nut | ||

|

Figure 24. Feed shaft return spring assembly.

Model G9986 8" Drill Press |