OPERATION, CONT’D

Choosing the Right Blade:

The rule of thumb for choosing a blade for a given application is that the harder and/ or thinner the material, the more teeth per inch are required. A list of TPI and materi- als to be cut follows.

TPI | Material |

24 | Sheet Metal / Stainless |

14 | Metal / Wood w/ Nails |

10⁄14 | Soft Metals / Wood |

10 | Wood |

6Rough Cut Wood

Choosing the Blade Speed:

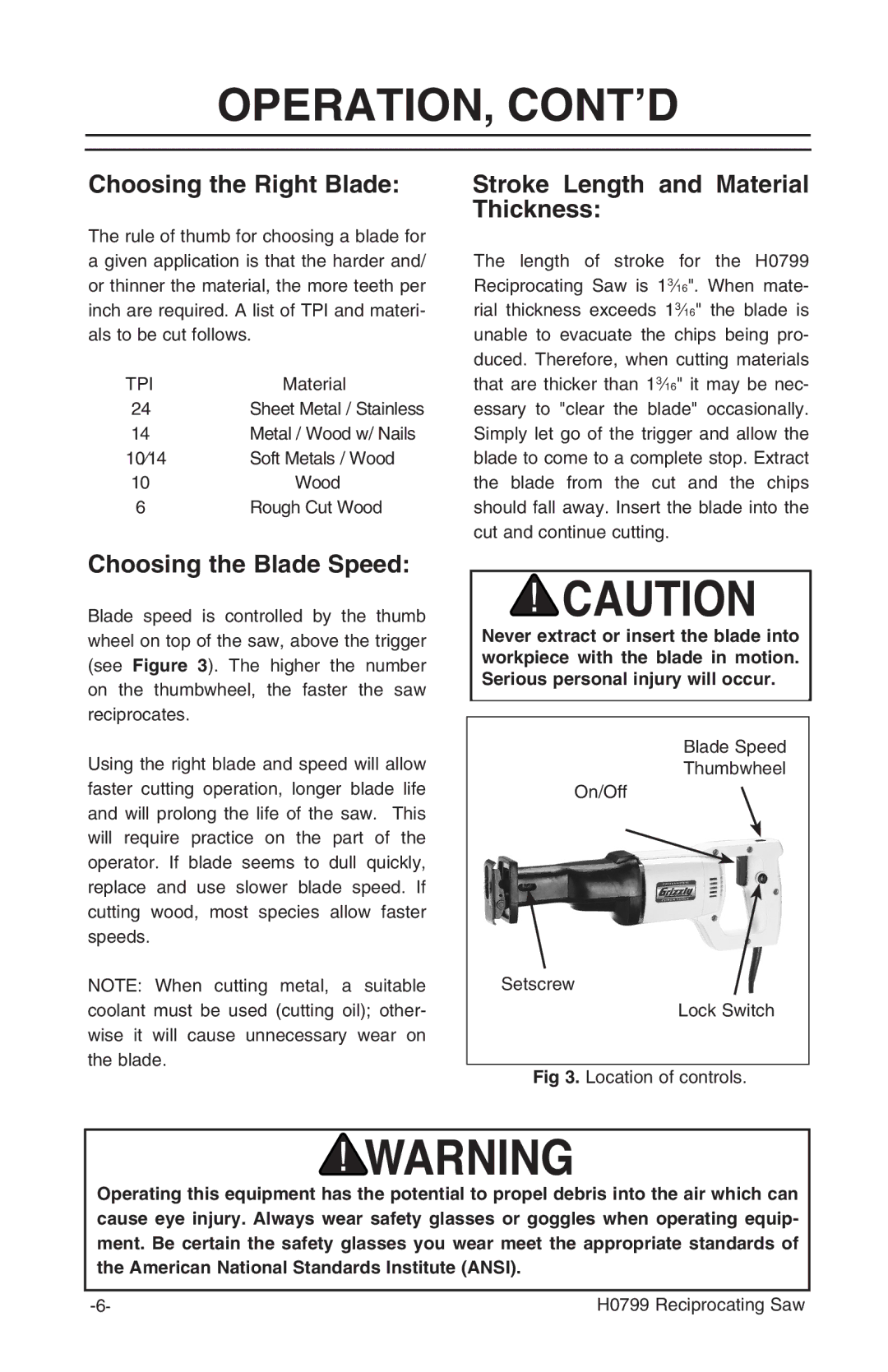

Blade speed is controlled by the thumb wheel on top of the saw, above the trigger (see Figure 3). The higher the number on the thumbwheel, the faster the saw reciprocates.

Using the right blade and speed will allow faster cutting operation, longer blade life and will prolong the life of the saw. This will require practice on the part of the operator. If blade seems to dull quickly, replace and use slower blade speed. If cutting wood, most species allow faster speeds.

NOTE: When cutting metal, a suitable coolant must be used (cutting oil); other- wise it will cause unnecessary wear on the blade.

Stroke Length and Material Thickness:

The length of stroke for the H0799 Reciprocating Saw is 13⁄16". When mate- rial thickness exceeds 13⁄16" the blade is unable to evacuate the chips being pro- duced. Therefore, when cutting materials that are thicker than 13⁄16" it may be nec- essary to "clear the blade" occasionally. Simply let go of the trigger and allow the blade to come to a complete stop. Extract the blade from the cut and the chips should fall away. Insert the blade into the cut and continue cutting.

Never extract or insert the blade into workpiece with the blade in motion. Serious personal injury will occur.

Blade Speed

Thumbwheel

On/Off

Setscrew

Lock Switch

Fig 3. Location of controls.

Operating this equipment has the potential to propel debris into the air which can cause eye injury. Always wear safety glasses or goggles when operating equip- ment. Be certain the safety glasses you wear meet the appropriate standards of the American National Standards Institute (ANSI).

H0799 Reciprocating Saw |