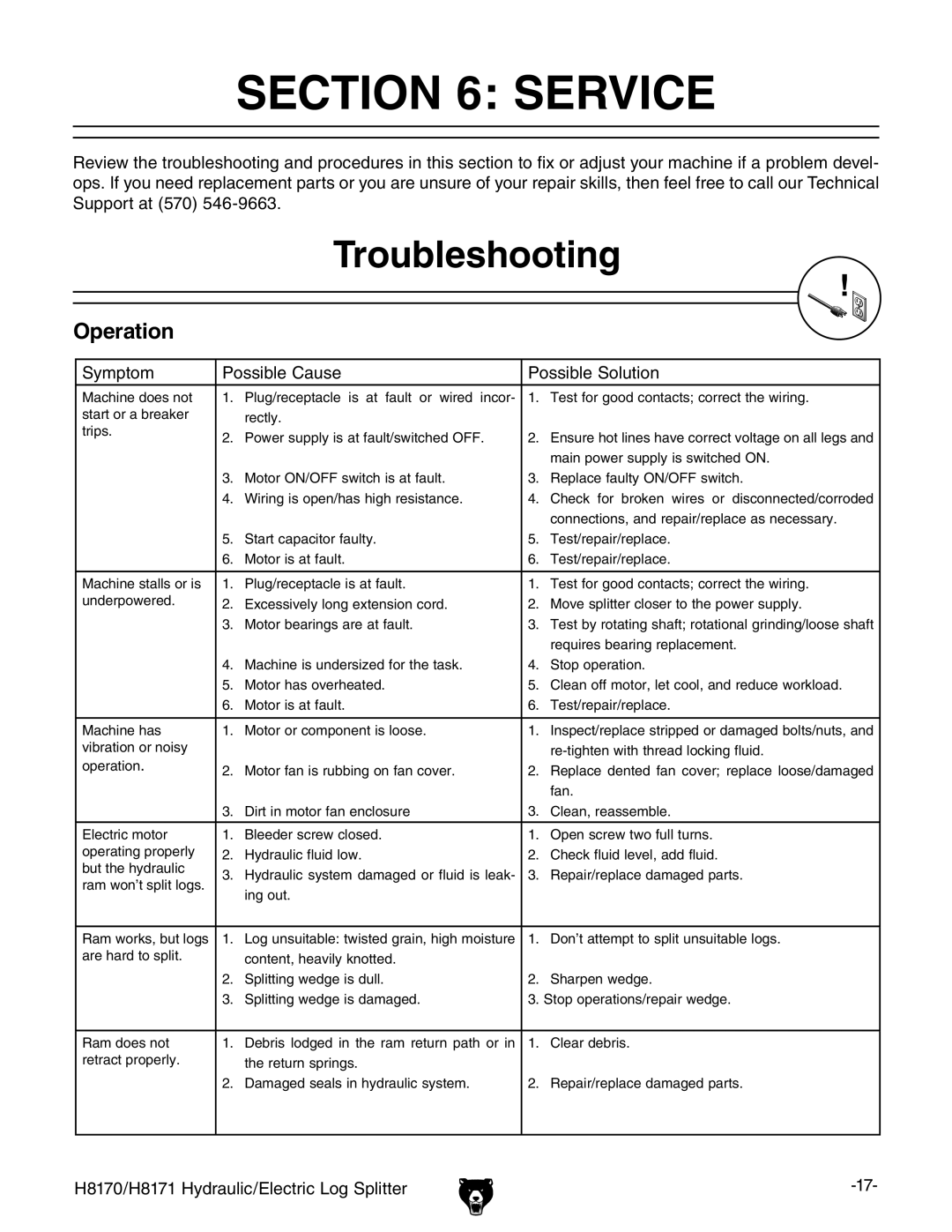

SECTION 6: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Operation Tshooting

Symptom | Possible Cause | Possible Solution | |||

Machine does not | 1. | Plug/receptacle is at fault or wired incor- | 1. | Test for good contacts; correct the wiring. | |

start or a breaker |

| rectly. |

|

| |

trips. | 2. | Power supply is at fault/switched OFF. | 2. | Ensure hot lines have correct voltage on all legs and | |

| |||||

|

|

|

| main power supply is switched ON. | |

| 3. | Motor ON/OFF switch is at fault. | 3. | Replace faulty ON/OFF switch. | |

| 4. | Wiring is open/has high resistance. | 4. | Check for broken wires or disconnected/corroded | |

|

|

|

| connections, and repair/replace as necessary. | |

| 5. | Start capacitor faulty. | 5. | Test/repair/replace. | |

| 6. | Motor is at fault. | 6. | Test/repair/replace. | |

|

|

|

|

| |

Machine stalls or is | 1. | Plug/receptacle is at fault. | 1. | Test for good contacts; correct the wiring. | |

underpowered. | 2. | Excessively long extension cord. | 2. | Move splitter closer to the power supply. | |

| 3. | Motor bearings are at fault. | 3. | Test by rotating shaft; rotational grinding/loose shaft | |

|

|

|

| requires bearing replacement. | |

| 4. | Machine is undersized for the task. | 4. | Stop operation. | |

| 5. | Motor has overheated. | 5. | Clean off motor, let cool, and reduce workload. | |

| 6. | Motor is at fault. | 6. | Test/repair/replace. | |

|

|

|

|

| |

Machine has | 1. | Motor or component is loose. | 1. | Inspect/replace stripped or damaged bolts/nuts, and | |

vibration or noisy |

|

|

| ||

operation. | 2. | Motor fan is rubbing on fan cover. | 2. | Replace dented fan cover; replace loose/damaged | |

| |||||

|

|

|

| fan. | |

| 3. | Dirt in motor fan enclosure | 3. | Clean, reassemble. | |

|

|

|

|

| |

Electric motor | 1. | Bleeder screw closed. | 1. | Open screw two full turns. | |

operating properly | 2. | Hydraulic fluid low. | 2. | Check fluid level, add fluid. | |

but the hydraulic | 3. | Hydraulic system damaged or fluid is leak- | 3. | Repair/replace damaged parts. | |

ram won’t split logs. | |||||

| ing out. |

|

| ||

|

|

|

| ||

|

|

|

|

| |

Ram works, but logs | 1. | Log unsuitable: twisted grain, high moisture | 1. | Don’t attempt to split unsuitable logs. | |

are hard to split. |

| content, heavily knotted. |

|

| |

| 2. | Splitting wedge is dull. | 2. | Sharpen wedge. | |

| 3. | Splitting wedge is damaged. | 3. Stop operations/repair wedge. | ||

|

|

|

|

| |

Ram does not | 1. | Debris lodged in the ram return path or in | 1. | Clear debris. | |

retract properly. |

| the return springs. |

|

| |

| 2. | Damaged seals in hydraulic system. | 2. | Repair/replace damaged parts. | |

|

|

|

| ||

H8170/H8171 Hydraulic/Electric Log Splitter |

| ||||