5.Fully insert the collet holder with the drill bit into the calibrating device, so the holder and device are flush and the pin fits into the collet holder notch as shown in Figure 12.

Notch

![]()

![]() Pin

Pin

Figure 12. Collet holder notch aligned with

adjusting device pin.

6.Turn the collet holder clockwise until it stops, push the bit forward as far as it will go into the calibrating device, then turn the bit clockwise until it stops, as shown in Figure 13 & 14.

Figure 13. Drill bit positioned in calibrating

device, top view.

H8203 Professional Drill Sharpening Machine

Figure 14. Drill bit positioned in calibrating

device, side view.

7.Thread the locking ring fully onto the collet holder, then remove the collet holder and drill bit from the machine.

8.Tug on the bit to verify that it is locked in the collet.

—If the bit moves, use a smaller collet size and repeat Steps 1-8.

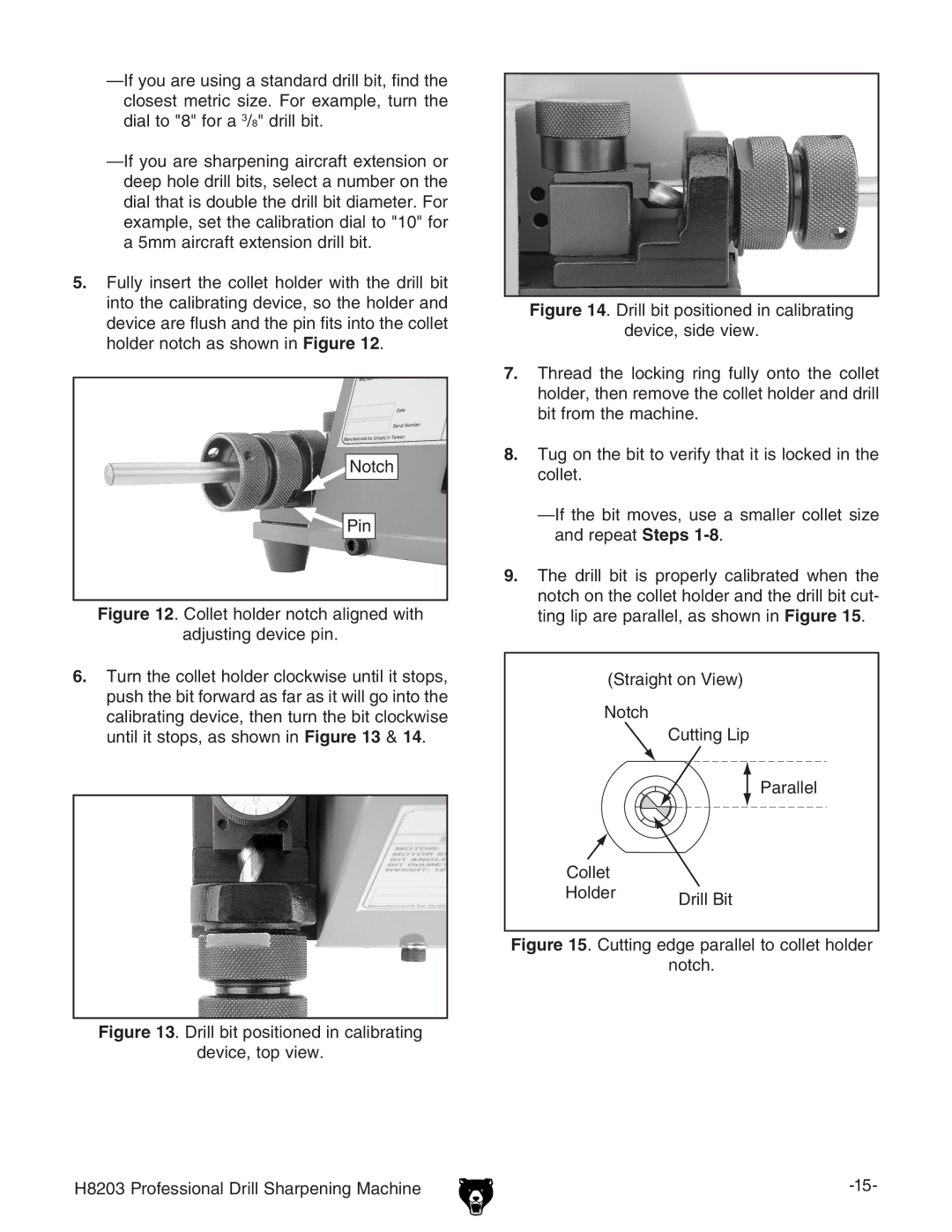

9.The drill bit is properly calibrated when the notch on the collet holder and the drill bit cut- ting lip are parallel, as shown in Figure 15.

������������������

�����

�����������

��������

�������

������ ���������