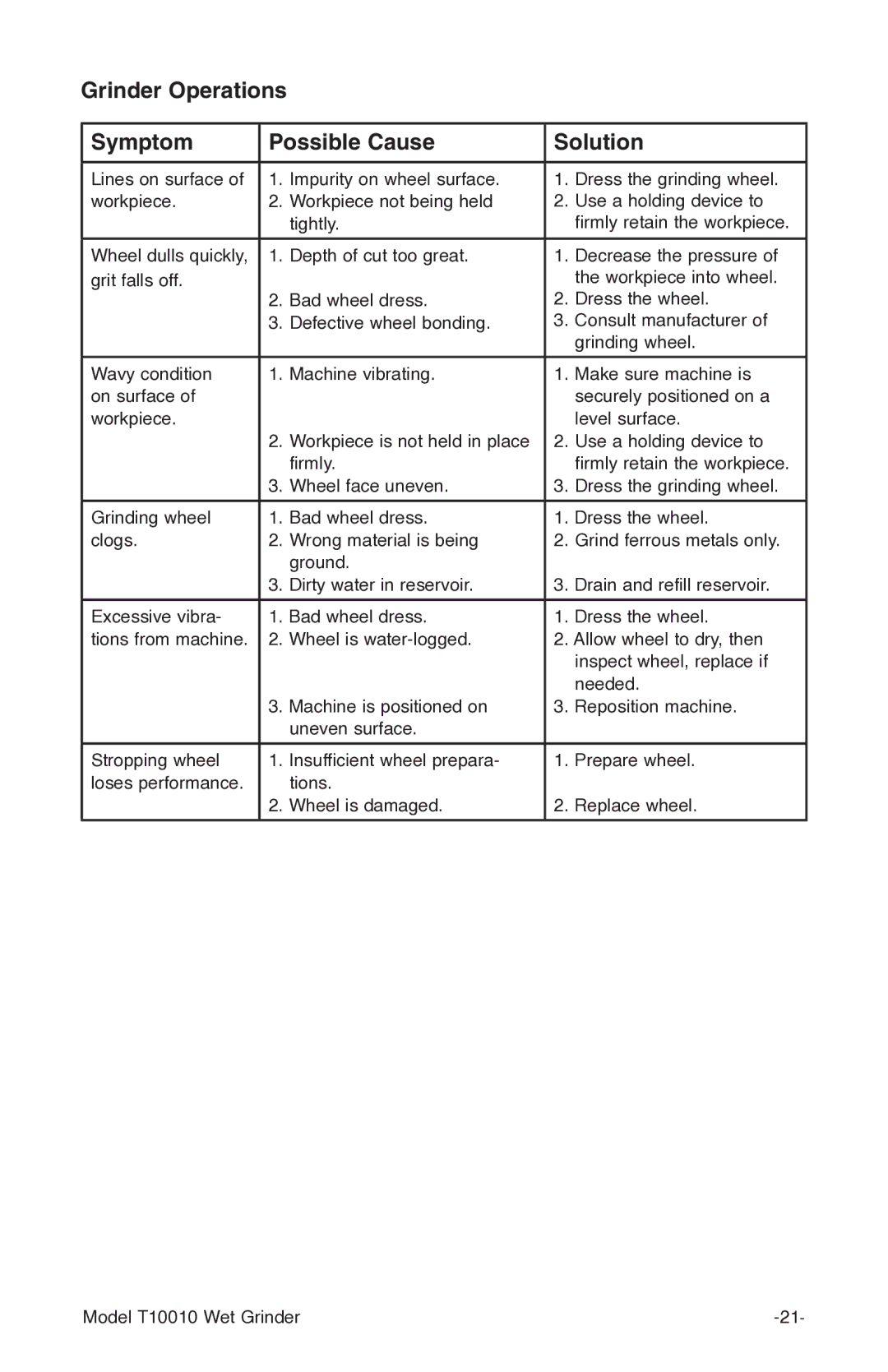

Grinder Operations

Symptom | Possible Cause | Solution | ||

|

|

|

|

|

Lines on surface of | 1. | Impurity on wheel surface. | 1. | Dress the grinding wheel. |

workpiece. | 2. | Workpiece not being held | 2. | Use a holding device to |

|

| tightly. |

| firmly retain the workpiece. |

Wheel dulls quickly, | 1. | Depth of cut too great. | 1. | Decrease the pressure of |

grit falls off. | 2. | Bad wheel dress. | 2. | the workpiece into wheel. |

| Dress the wheel. | |||

| 3. | Defective wheel bonding. | 3. | Consult manufacturer of |

|

|

|

| grinding wheel. |

Wavy condition | 1. | Machine vibrating. | 1. | Make sure machine is |

on surface of |

|

|

| securely positioned on a |

workpiece. |

|

|

| level surface. |

| 2. | Workpiece is not held in place | 2. | Use a holding device to |

|

| firmly. |

| firmly retain the workpiece. |

| 3. | Wheel face uneven. | 3. | Dress the grinding wheel. |

Grinding wheel | 1. | Bad wheel dress. | 1. | Dress the wheel. |

clogs. | 2. | Wrong material is being | 2. | Grind ferrous metals only. |

|

| ground. |

|

|

| 3. | Dirty water in reservoir. | 3. | Drain and refill reservoir. |

Excessive vibra- | 1. | Bad wheel dress. | 1. | Dress the wheel. |

tions from machine. | 2. | Wheel is | 2. Allow wheel to dry, then | |

|

|

|

| inspect wheel, replace if |

|

|

|

| needed. |

| 3. | Machine is positioned on | 3. | Reposition machine. |

|

| uneven surface. |

|

|

Stropping wheel | 1. | Insufficient wheel prepara- | 1. | Prepare wheel. |

loses performance. |

| tions. |

|

|

| 2. | Wheel is damaged. | 2. | Replace wheel. |

Model T10010 Wet Grinder |