9.Remove the bearings and bearing blocks from the cutterhead. There are numerous ways to do this, but avoid prying on them— they must be pulled off evenly and with care. If you are unsure about how to proceed, seek help from a mechanic/machinist, or numer- ous resources can be found on the internet.

Note: It is difficult to remove the bearings without damaging them. This is why we strongly recommend installing new bearings on the

10.Install bearings in the bearing blocks, then install the bearing blocks on the cutterhead. To avoid damaging the new bearings or the cutterhead shaft, use a arbor press or have a mechanic/machinist install these for you.

If neither of the above are acceptable options, install the bearings by gently tapping them with a block of wood and a rubber dead blow hammer. If you do this, take your time and make sure they install as evenly as possible.

11.

12.

13.Install the cutterhead (Figure 6) with the lock washers and hex nuts previously removed.

Figure 6. Example of spiral cutterhead installed.

14.Tighten the spiral cutterhead in place, and ensure both pulley setscrews are tight.

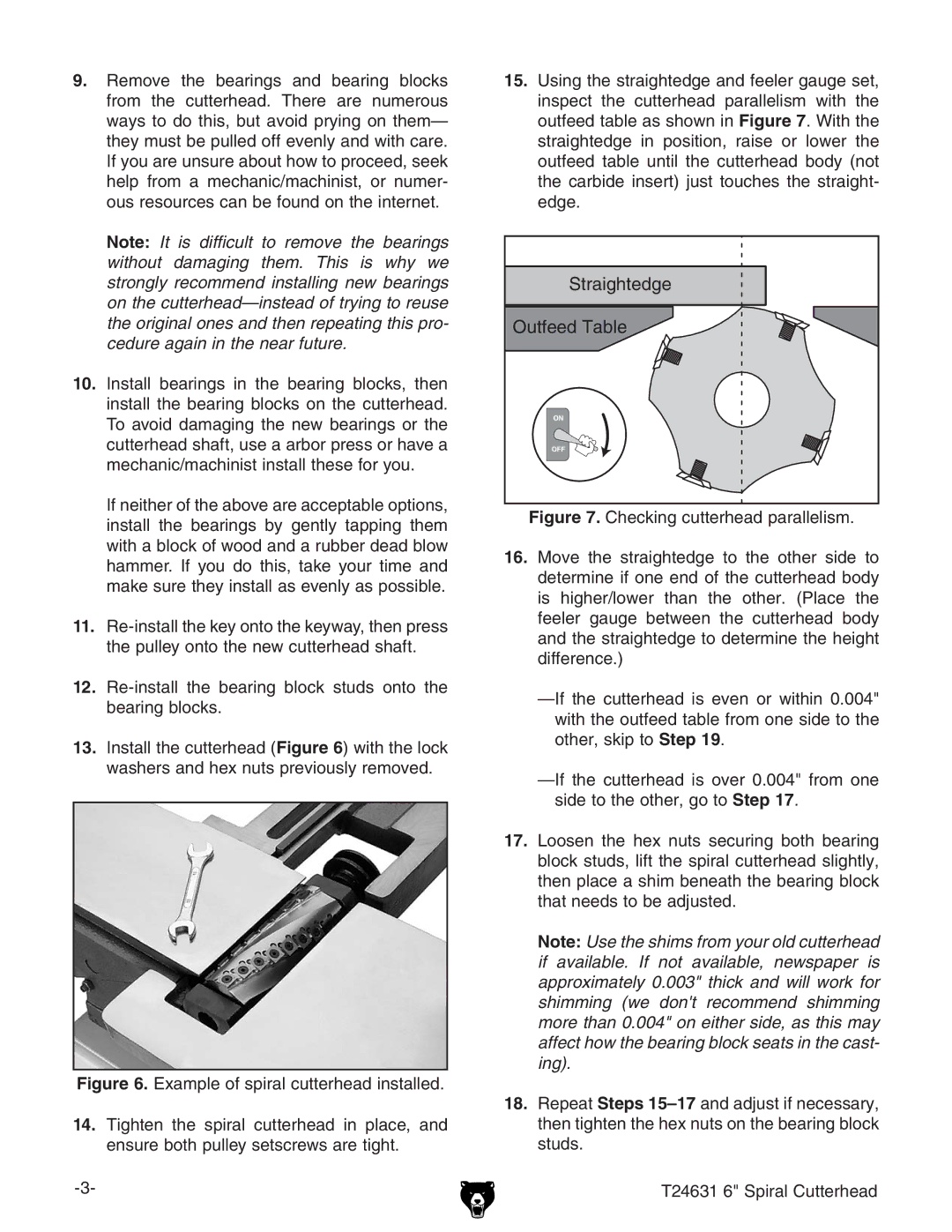

15.Using the straightedge and feeler gauge set, inspect the cutterhead parallelism with the outfeed table as shown in Figure 7. With the straightedge in position, raise or lower the outfeed table until the cutterhead body (not the carbide insert) just touches the straight- edge.

Straightedge |

Outfeed Table |

Figure 7. Checking cutterhead parallelism.

16.Move the straightedge to the other side to determine if one end of the cutterhead body is higher/lower than the other. (Place the feeler gauge between the cutterhead body and the straightedge to determine the height difference.)

—If the cutterhead is even or within 0.004" with the outfeed table from one side to the other, skip to Step 19.

—If the cutterhead is over 0.004" from one side to the other, go to Step 17.

17.Loosen the hex nuts securing both bearing block studs, lift the spiral cutterhead slightly, then place a shim beneath the bearing block that needs to be adjusted.

Note: Use the shims from your old cutterhead if available. If not available, newspaper is approximately 0.003" thick and will work for shimming (we don't recommend shimming more than 0.004" on either side, as this may affect how the bearing block seats in the cast- ing).