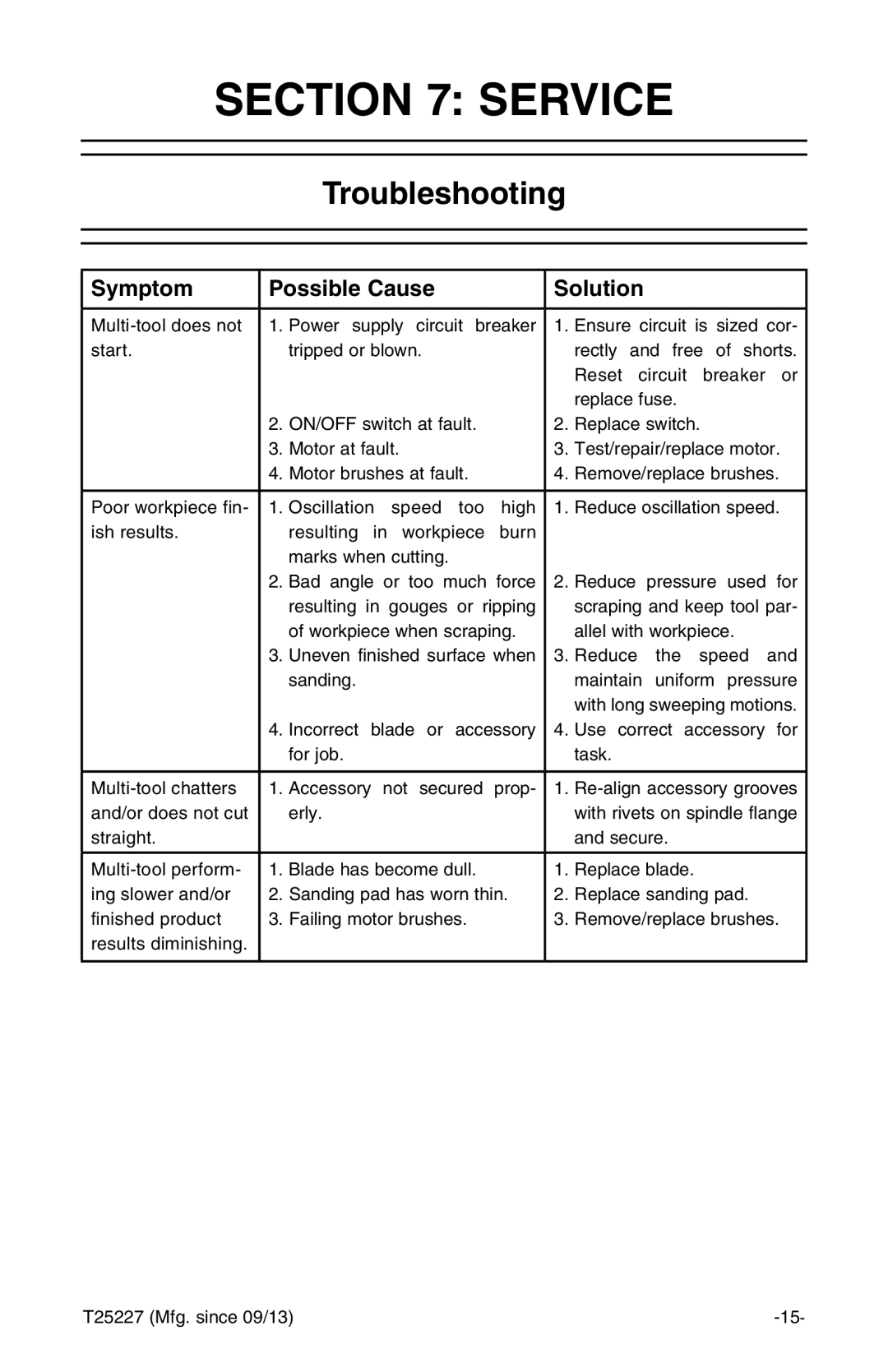

SECTION 7: SERVICE

Troubleshooting

Symptom | Possible Cause |

|

| Solution |

|

|

| |||

|

|

|

|

| ||||||

1. | Power supply circuit breaker | 1. | Ensure circuit is sized cor- | |||||||

start. |

| tripped or blown. |

|

|

| rectly and free of shorts. | ||||

|

|

|

|

|

|

| Reset circuit | breaker | or | |

|

|

|

|

|

|

| replace fuse. |

|

| |

| 2. | ON/OFF switch at fault. |

| 2. | Replace switch. |

| ||||

| 3. | Motor at fault. |

|

| 3. | Test/repair/replace motor. | ||||

| 4. | Motor brushes at fault. |

| 4. | Remove/replace brushes. | |||||

|

|

|

|

|

|

| ||||

Poor workpiece fin- | 1. oscillation | speed | too | high | 1. | Reduce oscillation speed. | ||||

ish results. |

| resulting in | workpiece | burn |

|

|

|

|

| |

|

| marks when cutting. |

|

|

|

|

|

|

| |

| 2. | Bad angle or too much force | 2. | Reduce | pressure used | for | ||||

|

| resulting in gouges or ripping |

| scraping and keep tool par- | ||||||

|

| of workpiece when scraping. |

| allel with workpiece. |

| |||||

| 3. | Uneven finished surface when | 3. reduce | the | speed | and | ||||

|

| sanding. |

|

|

|

| maintain | uniform pressure | ||

|

|

|

|

|

|

| with long sweeping motions. | |||

| 4. | Incorrect blade or | accessory | 4. | Use correct accessory | for | ||||

|

| for job. |

|

|

|

| task. |

|

|

|

|

|

|

|

| ||||||

1. | Accessory not secured prop- | 1. | ||||||||

and/or does not cut |

| erly. |

|

|

|

| with rivets on spindle flange | |||

straight. |

|

|

|

|

|

| and secure. |

|

| |

|

|

|

|

|

|

|

| |||

1. | Blade has become dull. |

| 1. | Replace blade. |

|

| ||||

ing slower and/or | 2. | Sanding pad has worn thin. | 2. | Replace sanding pad. |

| |||||

finished product | 3. | Failing motor brushes. |

| 3. | Remove/replace brushes. | |||||

results diminishing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T25227 (Mfg. since 09/13) |