Cleanup

The unpainted surfaces of your machine are coated with a

Be patient and do a thorough job cleaning your machine. The time you spend doing this now will give you a better appreciation for the proper care of your machine's unpainted surfaces.

There are many ways to remove this rust preven- tative, but the following steps work well in a wide variety of situations. Always follow the manufac- turer’s instructions with any cleaning product you use and make sure you work in a

Before cleaning, gather the following:

•Disposable Rags

•Cleaner/degreaser (WD•40 works well)

•Safety glasses & disposable gloves

•Plastic paint scraper (optional)

Basic steps for removing rust preventative:

1.Put on safety glasses.

2.Coat the rust preventative with a liberal amount of cleaner/degreaser, then let it soak for

3.Wipe off the surfaces. If your cleaner/degreas- er is effective, the rust preventative will wipe off easily. If you have a plastic paint scraper, scrape off as much as you can first, then wipe off the rest with the rag.

4.Repeat Steps

NOTICE

Avoid

Model T26417/T26418 (Mfd. Since 11/13)

Site Considerations

Workbench Load

Refer to the Machine Data Sheet for the weight and footprint specifications of your machine. Some workbenches may require additional rein- forcement to support the weight of the machine and workpiece materials.

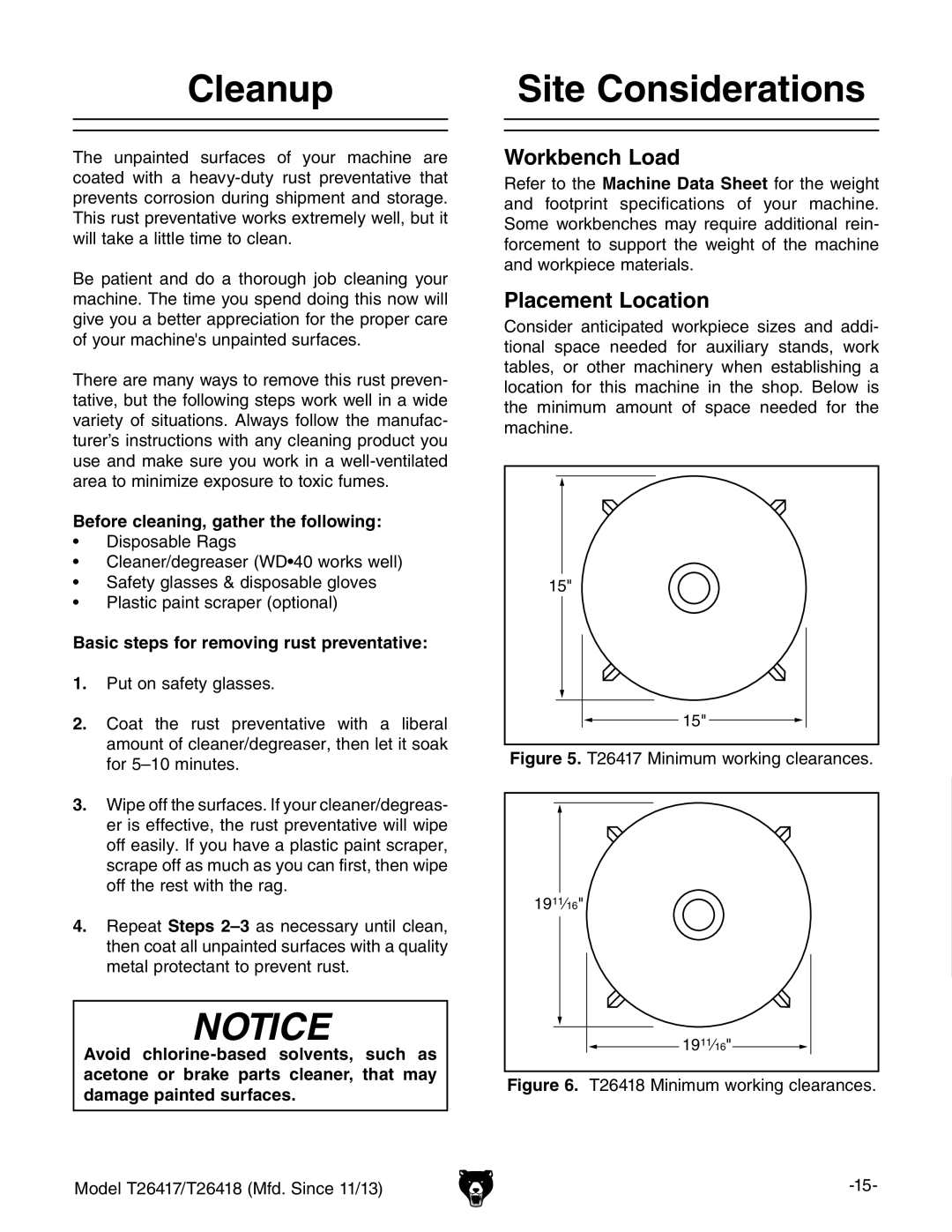

Placement Location

Consider anticipated workpiece sizes and addi- tional space needed for auxiliary stands, work tables, or other machinery when establishing a location for this machine in the shop. Below is the minimum amount of space needed for the machine.

15"

15"

Figure 5. T26417 Minimum working clearances.

1911⁄16"

1911⁄16"