SECTION 6: MAINTENANCE

To reduce risk of shock or accidental startup, always disconnect machine from power before adjustments, maintenance, or service.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Loose mounting bolts.

•Sanding drums and sleeves for wear or dam- age.

•Worn or damaged wires.

•Any other unsafe condition.

Lubrication

The bearings in the motor are shielded, perma- nently lubricated and require no maintenance.

Every month, the table tilt assembly should be cleaned and greased to prevent corrosion and keep the table moving freely.

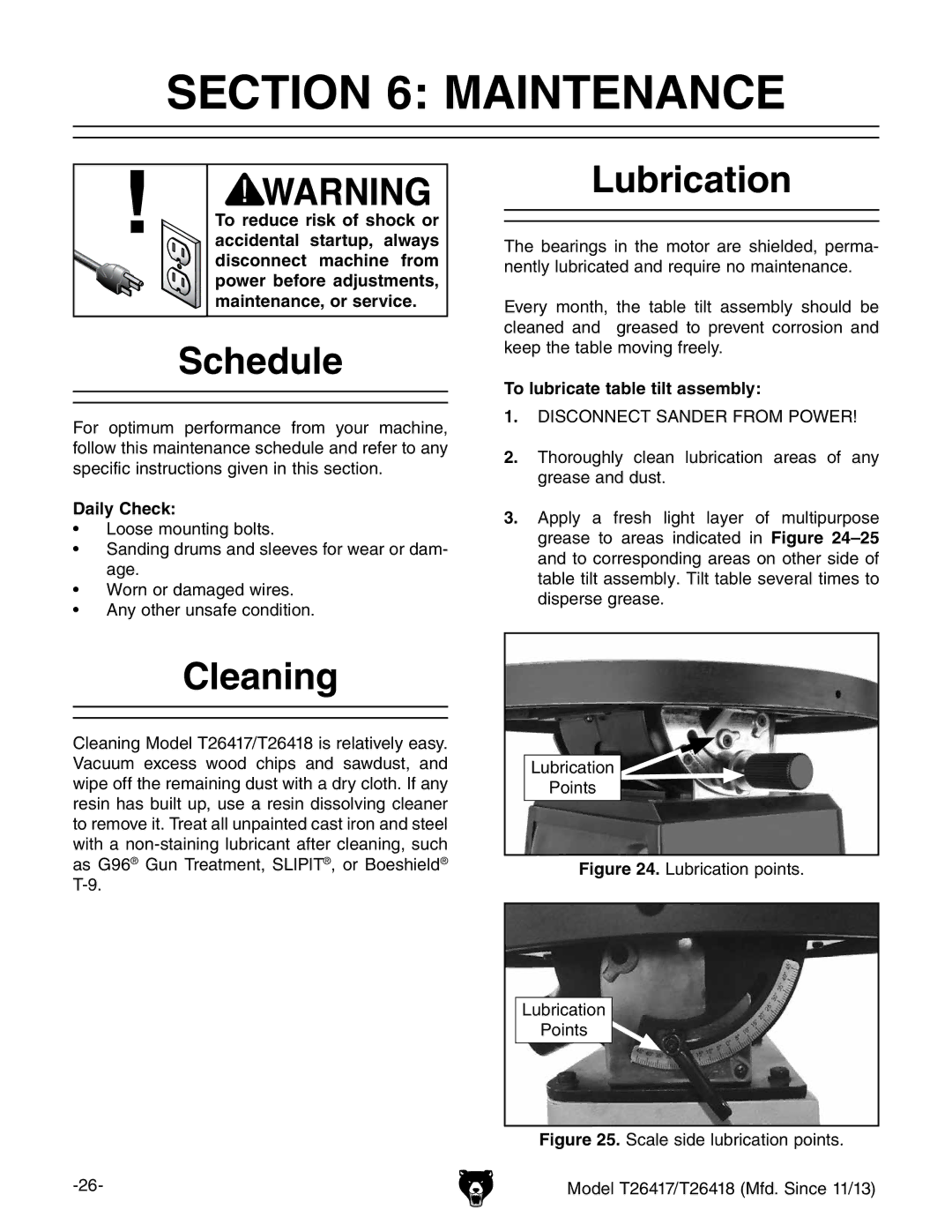

To lubricate table tilt assembly:

1.DISCONNECT SANDER FROM POWER!

2.Thoroughly clean lubrication areas of any grease and dust.

3.Apply a fresh light layer of multipurpose grease to areas indicated in Figure

Cleaning

Cleaning Model T26417/T26418 is relatively easy. Vacuum excess wood chips and sawdust, and wipe off the remaining dust with a dry cloth. If any resin has built up, use a resin dissolving cleaner to remove it. Treat all unpainted cast iron and steel with a

Lubrication![]()

Points

Figure 24. Lubrication points.

Lubrication