Assembly |

| Dust Collection |

|

|

|

|

|

|

Place the spindle assemblies and table inserts in the

Table Insert

Holder

Spindle

Assembly

Holder

Figure 10. Table insert and spindle assembly

holder.

Model T26417/T26418 (Mfd. Since 11/13)

This machine creates substantial amounts of dust during operation. Breathing air- borne dust on a regular basis can result in permanent respiratory illness. Reduce your risk by wearing a respirator and capturing the dust with a dust collection system.

Recommended CFM at Dust Port: 200 CFM

Do not confuse this CFM recommendation with the rating of the dust collector. To determine the CFM at the dust port, you must consider these variables: (1) CFM rating of the dust collector,

(2)hose type and length between the dust col- lector and the machine, (3) number of branches or wyes, and (4) amount of other open lines throughout the system. Explaining how to cal- culate these variables is beyond the scope of this manual. Consult an expert or purchase a good dust collection

To connect a dust collection hose:

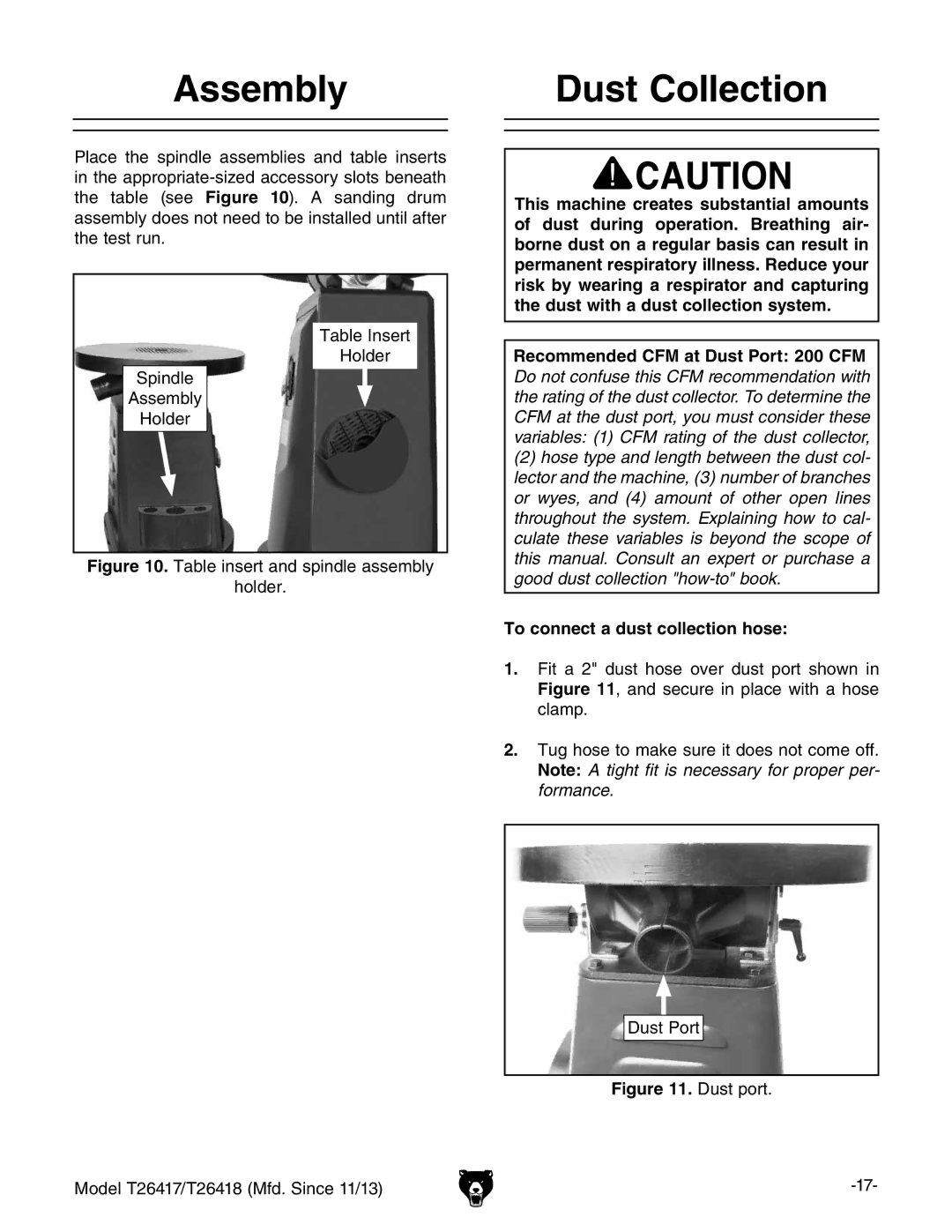

1.Fit a 2" dust hose over dust port shown in Figure 11, and secure in place with a hose clamp.

2.Tug hose to make sure it does not come off. Note: A tight fit is necessary for proper per- formance.

Dust Port