Section 2 – Installation

QUIETPACT™ 75D Recreational Vehicle Generator

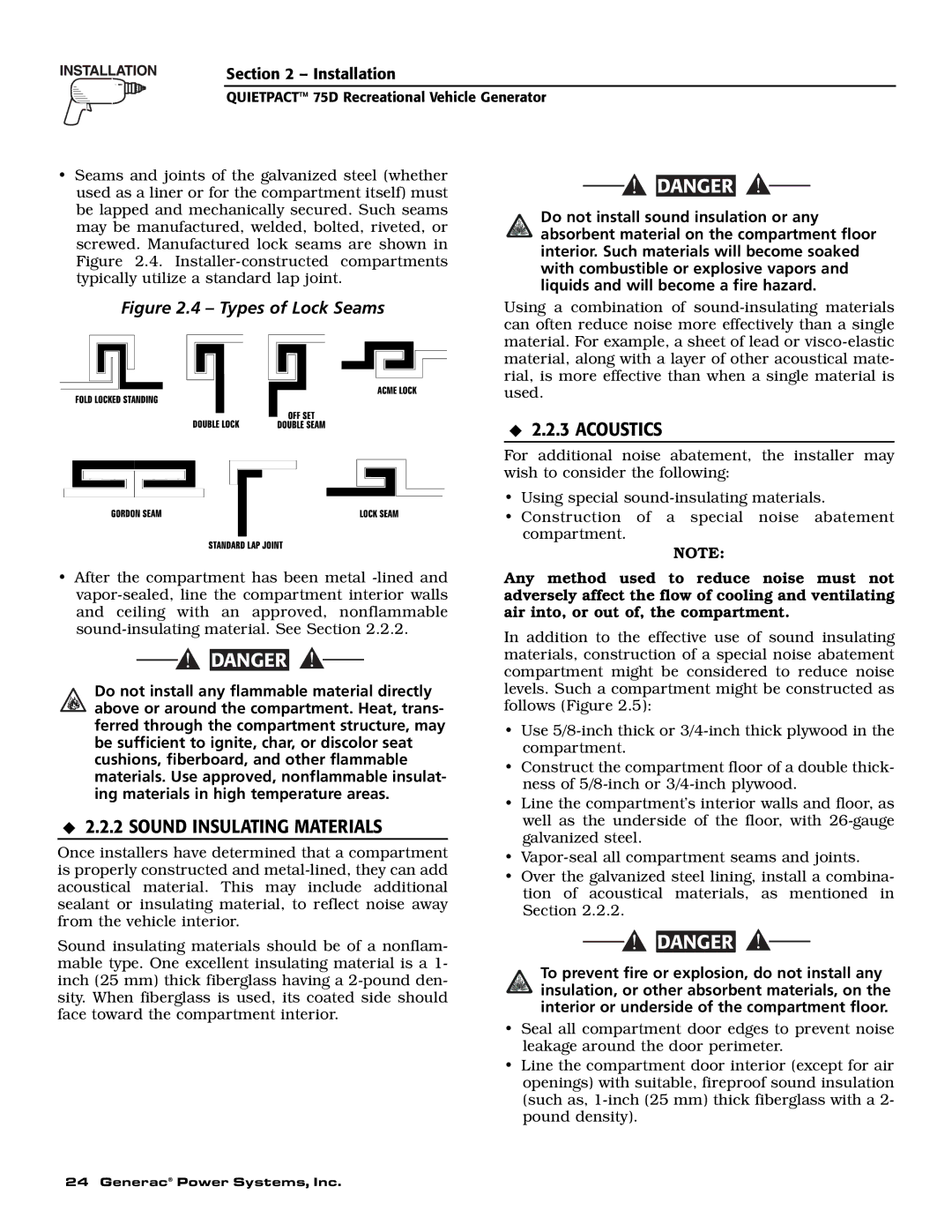

•Seams and joints of the galvanized steel (whether used as a liner or for the compartment itself) must be lapped and mechanically secured. Such seams may be manufactured, welded, bolted, riveted, or screwed. Manufactured lock seams are shown in Figure 2.4.

Figure 2.4 – Types of Lock Seams

![]()

![]() DANGER

DANGER

Do not install sound insulation or any absorbent material on the compartment floor interior. Such materials will become soaked with combustible or explosive vapors and liquids and will become a fire hazard.

Using a combination of

•After the compartment has been metal

![]()

![]() DANGER

DANGER

Do not install any flammable material directly above or around the compartment. Heat, trans- ferred through the compartment structure, may be sufficient to ignite, char, or discolor seat cushions, fiberboard, and other flammable materials. Use approved, nonflammable insulat- ing materials in high temperature areas.

◆2.2.2 SOUND INSULATING MATERIALS

Once installers have determined that a compartment is properly constructed and

Sound insulating materials should be of a nonflam- mable type. One excellent insulating material is a 1- inch (25 mm) thick fiberglass having a

◆2.2.3 ACOUSTICS

For additional noise abatement, the installer may wish to consider the following:

•Using special

•Construction of a special noise abatement compartment.

NOTE:

Any method used to reduce noise must not adversely affect the flow of cooling and ventilating air into, or out of, the compartment.

In addition to the effective use of sound insulating materials, construction of a special noise abatement compartment might be considered to reduce noise levels. Such a compartment might be constructed as follows (Figure 2.5):

•Use

•Construct the compartment floor of a double thick- ness of

•Line the compartment’s interior walls and floor, as well as the underside of the floor, with

•

•Over the galvanized steel lining, install a combina- tion of acoustical materials, as mentioned in Section 2.2.2.

![]()

![]() DANGER

DANGER

To prevent fire or explosion, do not install any insulation, or other absorbent materials, on the interior or underside of the compartment floor.

•Seal all compartment door edges to prevent noise leakage around the door perimeter.

•Line the compartment door interior (except for air openings) with suitable, fireproof sound insulation (such as,

24 Generac® Power Systems, Inc.