Section 3 – Maintenance

QUIETPACT™ 75D Recreational Vehicle Generator

8.Screw the new filter on by hand, until its gasket lightly contacts the oil filter adapter. Then, tight- en the filter an additional 3/4 to one turn.

9.Remove the dipstick, and wipe it dry with a clean,

10.Remove the

11.Install the

12.Reinstall the air filter.

13.Reattach the front service door; make sure the latches are fully engaged.

14.Start the engine, and check for leaks.

NOTE:

Check the oil level and fill to the “FULL” mark, after checking for leaks. The filter will retain some oil.

3.3SERVICING THE ENGINE

AIR FILTER

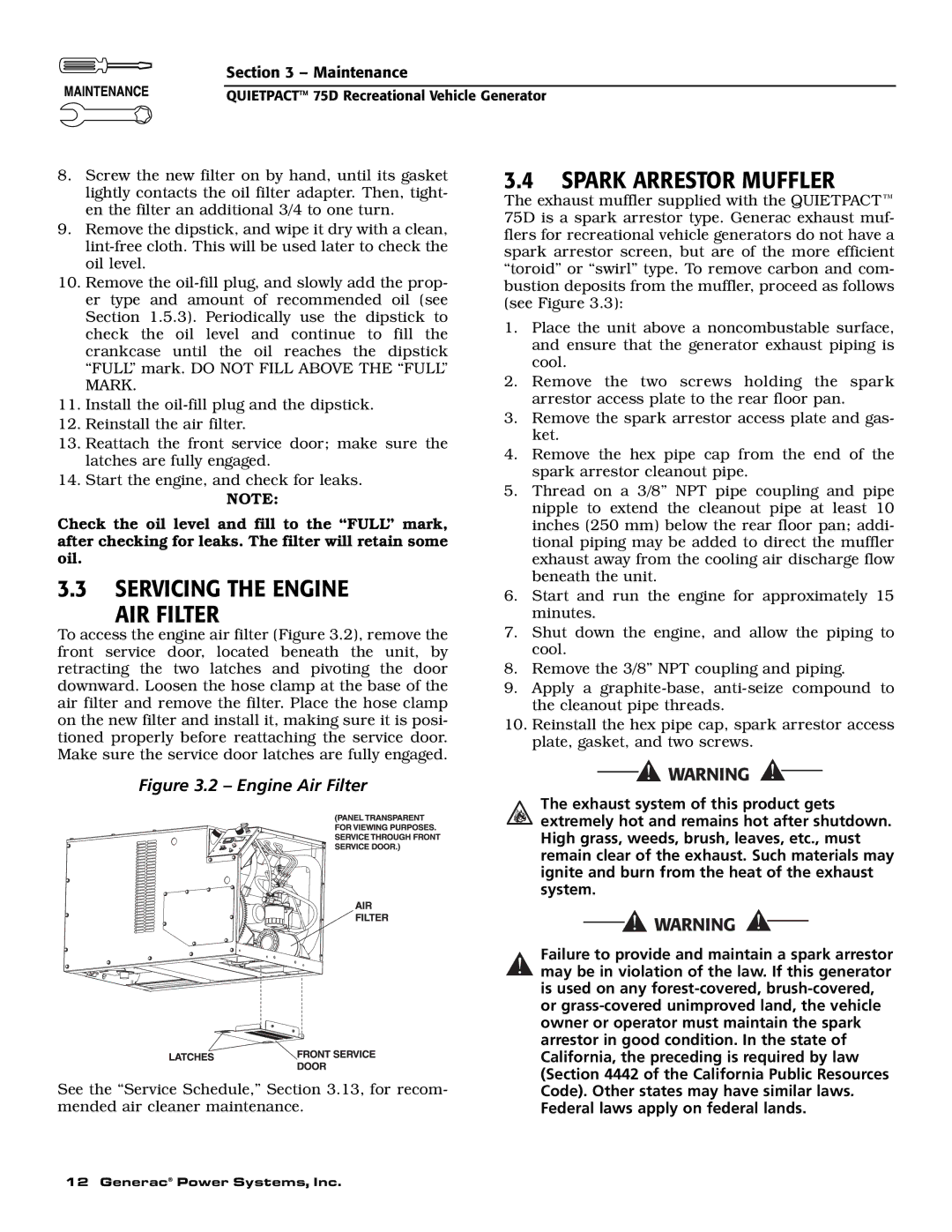

To access the engine air filter (Figure 3.2), remove the front service door, located beneath the unit, by retracting the two latches and pivoting the door downward. Loosen the hose clamp at the base of the air filter and remove the filter. Place the hose clamp on the new filter and install it, making sure it is posi- tioned properly before reattaching the service door. Make sure the service door latches are fully engaged.

Figure 3.2 – Engine Air Filter

3.4SPARK ARRESTOR MUFFLER

The exhaust muffler supplied with the QUIETPACT™ 75D is a spark arrestor type. Generac exhaust muf- flers for recreational vehicle generators do not have a spark arrestor screen, but are of the more efficient “toroid” or “swirl” type. To remove carbon and com- bustion deposits from the muffler, proceed as follows (see Figure 3.3):

1.Place the unit above a noncombustable surface, and ensure that the generator exhaust piping is cool.

2.Remove the two screws holding the spark arrestor access plate to the rear floor pan.

3.Remove the spark arrestor access plate and gas- ket.

4.Remove the hex pipe cap from the end of the spark arrestor cleanout pipe.

5.Thread on a 3/8” NPT pipe coupling and pipe nipple to extend the cleanout pipe at least 10 inches (250 mm) below the rear floor pan; addi- tional piping may be added to direct the muffler exhaust away from the cooling air discharge flow beneath the unit.

6.Start and run the engine for approximately 15 minutes.

7.Shut down the engine, and allow the piping to cool.

8.Remove the 3/8” NPT coupling and piping.

9.Apply a

10.Reinstall the hex pipe cap, spark arrestor access plate, gasket, and two screws.

See the “Service Schedule,” Section 3.13, for recom- mended air cleaner maintenance.

The exhaust system of this product gets extremely hot and remains hot after shutdown. High grass, weeds, brush, leaves, etc., must remain clear of the exhaust. Such materials may ignite and burn from the heat of the exhaust system.

Failure to provide and maintain a spark arrestor

!may be in violation of the law. If this generator is used on any

12 Generac® Power Systems, Inc.