Section 4 — Maintenance

Guardian

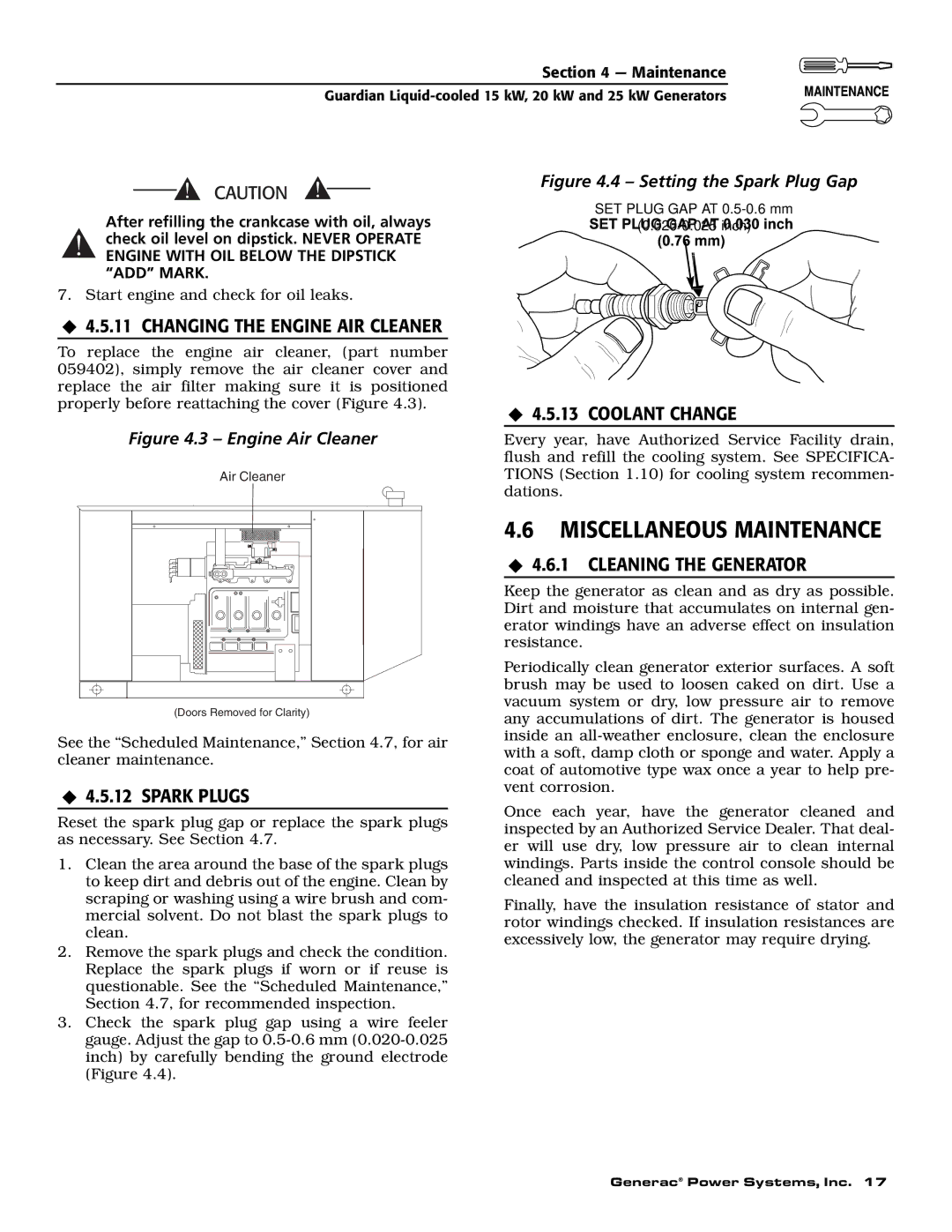

Figure 4.4 – Setting the Spark Plug Gap

After refilling the crankcase with oil, always

!check oil level on dipstick. NEVER OPERATE ENGINE WITH OIL BELOW THE DIPSTICK “ADD” MARK.

7.Start engine and check for oil leaks.

4.5.11 CHANGING THE ENGINE AIR CLEANER

To replace the engine air cleaner, (part number 059402), simply remove the air cleaner cover and replace the air filter making sure it is positioned properly before reattaching the cover (Figure 4.3).

Figure 4.3 – Engine Air Cleaner

Air Cleaner

(Doors Removed for Clarity)

See the “Scheduled Maintenance,” Section 4.7, for air cleaner maintenance.

4.5.12 SPARK PLUGS

Reset the spark plug gap or replace the spark plugs as necessary. See Section 4.7.

1.Clean the area around the base of the spark plugs to keep dirt and debris out of the engine. Clean by scraping or washing using a wire brush and com- mercial solvent. Do not blast the spark plugs to clean.

2.Remove the spark plugs and check the condition. Replace the spark plugs if worn or if reuse is questionable. See the “Scheduled Maintenance,” Section 4.7, for recommended inspection.

3.Check the spark plug gap using a wire feeler gauge. Adjust the gap to

SET PLUG GAP AT

![]()

![]()

![]()

![]()

![]() (0.020-0.025

(0.020-0.025![]()

![]()

![]()

![]()

![]()

4.5.13 COOLANT CHANGE

Every year, have Authorized Service Facility drain, flush and refill the cooling system. See SPECIFICA- TIONS (Section 1.10) for cooling system recommen- dations.

4.6MISCELLANEOUS MAINTENANCE

4.6.1 CLEANING THE GENERATOR

Keep the generator as clean and as dry as possible. Dirt and moisture that accumulates on internal gen- erator windings have an adverse effect on insulation resistance.

Periodically clean generator exterior surfaces. A soft brush may be used to loosen caked on dirt. Use a vacuum system or dry, low pressure air to remove any accumulations of dirt. The generator is housed inside an

Once each year, have the generator cleaned and inspected by an Authorized Service Dealer. That deal- er will use dry, low pressure air to clean internal windings. Parts inside the control console should be cleaned and inspected at this time as well.

Finally, have the insulation resistance of stator and rotor windings checked. If insulation resistances are excessively low, the generator may require drying.

Generac® Power Systems, Inc. 17