Installation

Caution: Installation should be completed by a qualified technician. Before at- tempting installation of the Air Horns, remove the keys from the vehicle igni- tion, and place wheel chocks on both sides of at least 2 wheels. Make sure engine and engine compartment is cool before beginning work.

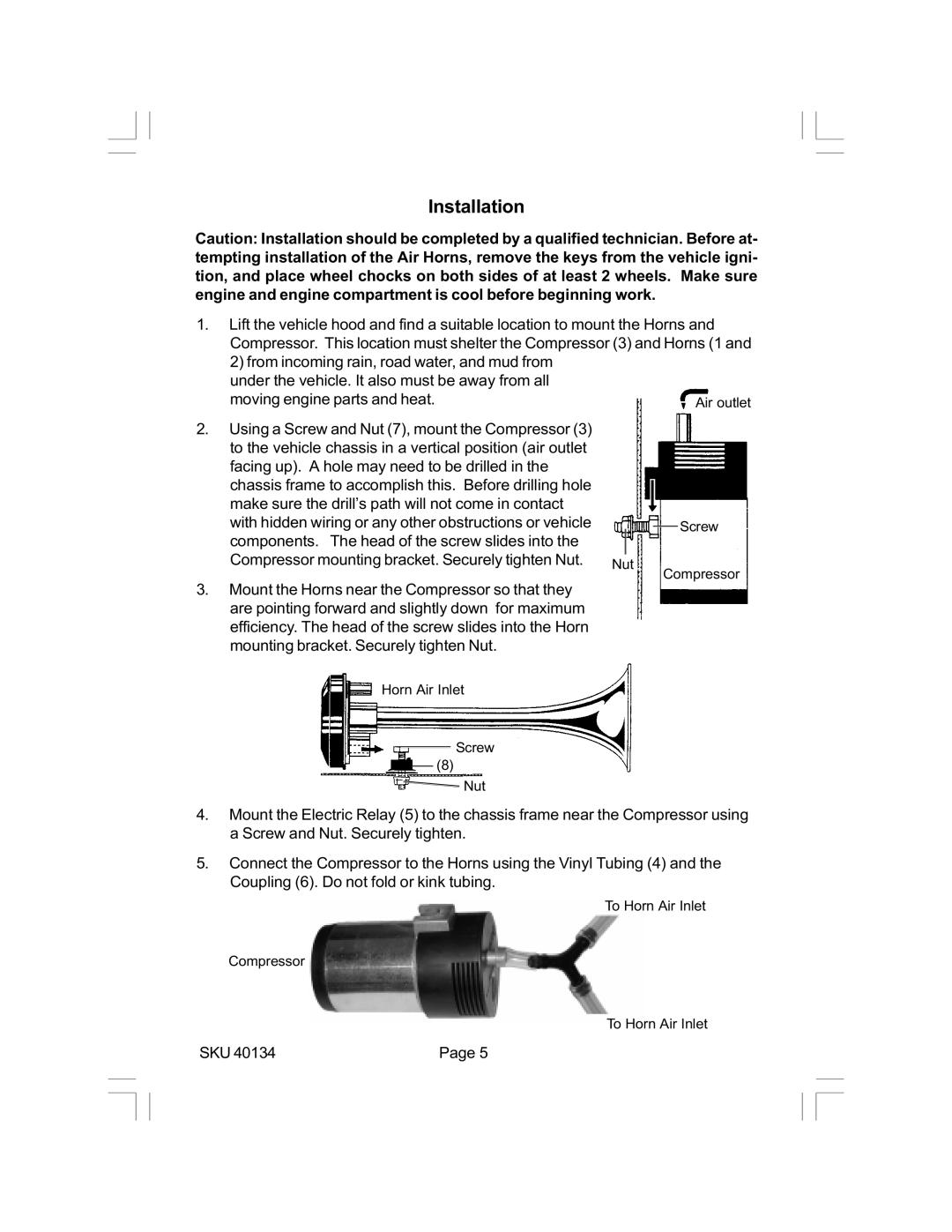

1.Lift the vehicle hood and find a suitable location to mount the Horns and Compressor. This location must shelter the Compressor (3) and Horns (1 and 2) from incoming rain, road water, and mud from

under the vehicle. It also must be away from all moving engine parts and heat.

2.Using a Screw and Nut (7), mount the Compressor (3) to the vehicle chassis in a vertical position (air outlet facing up). A hole may need to be drilled in the chassis frame to accomplish this. Before drilling hole make sure the drill’s path will not come in contact

with hidden wiring or any other obstructions or vehicle |

|

|

| Screw | ||||

|

|

| ||||||

|

|

| ||||||

components. The head of the screw slides into the |

|

|

|

| ||||

Compressor mounting bracket. Securely tighten Nut. |

|

|

|

| ||||

Nut | ||||||||

|

|

|

|

|

|

| Compressor | |

3. Mount the Horns near the Compressor so that they |

|

|

|

| ||||

are pointing forward and slightly down for maximum |

|

|

|

| ||||

efficiency. The head of the screw slides into the Horn |

|

|

|

| ||||

mounting bracket. Securely tighten Nut. |

|

|

|

| ||||

Horn Air Inlet |

|

|

|

| ||||

|

|

|

| Screw |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| (8) |

|

|

|

| |

|

|

|

|

|

|

| ||

|

|

|

| Nut |

|

|

|

|

4.Mount the Electric Relay (5) to the chassis frame near the Compressor using a Screw and Nut. Securely tighten.

5.Connect the Compressor to the Horns using the Vinyl Tubing (4) and the Coupling (6). Do not fold or kink tubing.

To Horn Air Inlet

Compressor

To Horn Air Inlet

SKU 40134 | Page 5 |