68284, 68285 specifications

Harbor Freight Tools, a prominent discount tool retailer in the United States, offers a wide range of tools and equipment for both DIY enthusiasts and professionals. Among its extensive product lineup, two notable items are the Harbor Freight Tools model 68285 and model 68284. These tools feature advanced technologies and characteristics that cater to various user needs.The Harbor Freight Tools 68285 is a multi-tool that stands out for its versatility and function. It's designed with a powerful motor, making it efficient in performing tasks ranging from cutting to sanding. This model features a variable speed control, allowing users to adjust the speed according to the material and task at hand. The oscillating tool design enables precision work in tight spaces, making it an ideal choice for intricate cuts or detailed designs. Its ergonomic handle provides comfort during prolonged use, reducing fatigue and enhancing control.

On the other hand, the Harbor Freight Tools 68284 represents a high-performance oscillating tool. This model emphasizes user-friendly features, including easy blade changes without the need for additional tools. The 68284 is equipped with a powerful motor, ensuring that it can handle heavy-duty applications efficiently. It also includes various attachments to enhance capabilities, such as sanding pads, blades for cutting wood and metal, and scraping tools, which makes it a complete solution for a range of projects.

Both models incorporate advanced technologies that enhance their usability. They are designed with durable construction, ensuring longevity even under rigorous use. The 68285 and 68284 models both feature a compact design, promoting ease of storage and transport.

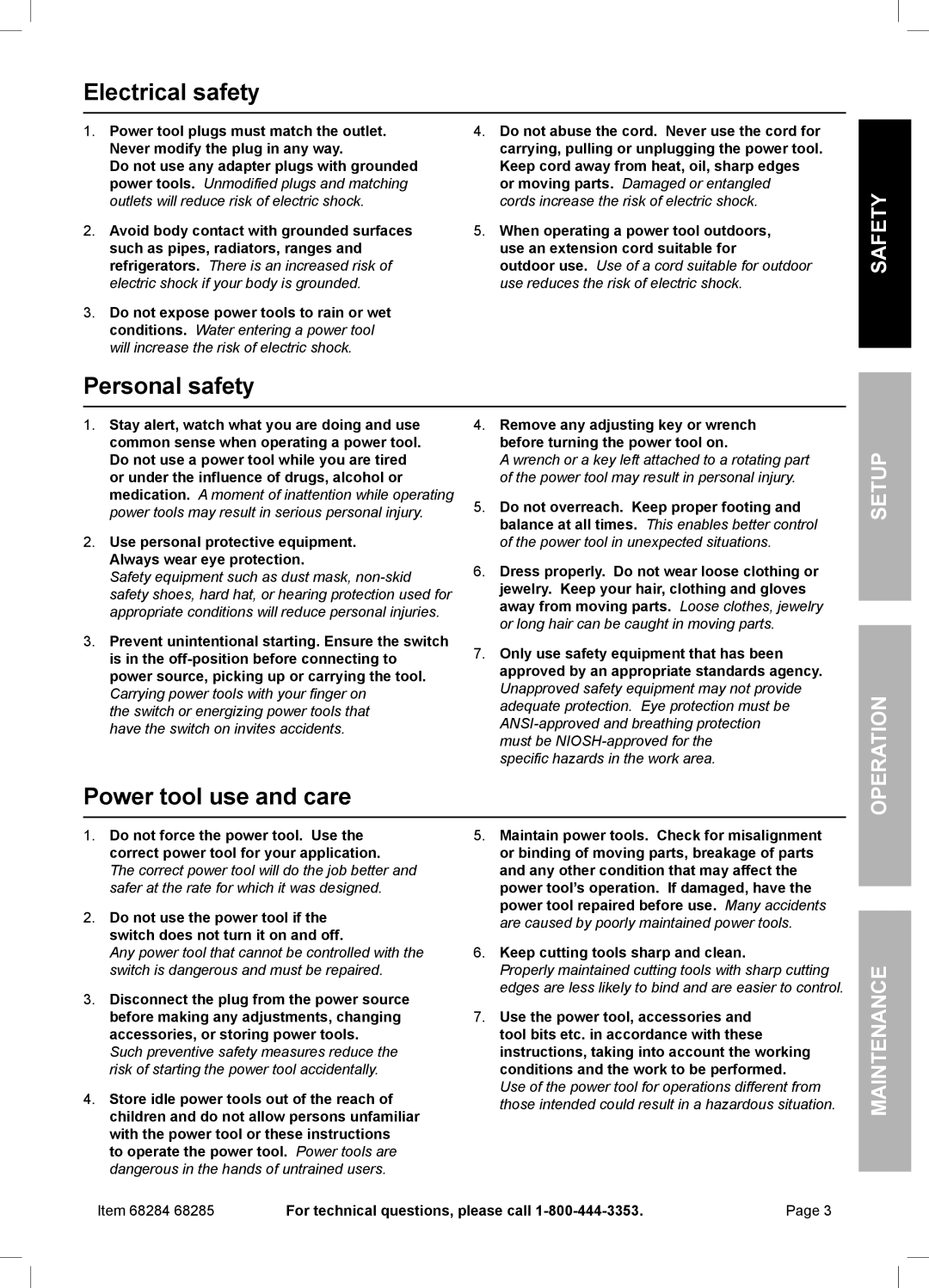

In terms of safety, these tools come equipped with protective features to minimize the risk of accidents. The soft grip handles are engineered for maximum comfort, while the robust power systems provide reliable performance. These aspects make them suitable for both novice users and seasoned professionals tackling everyday tasks or specialized projects.

Ultimately, the Harbor Freight Tools 68285 and 68284 models exemplify the brand's commitment to quality and affordability. By combining innovative designs and practical features, they provide users with reliable tools that meet a variety of needs, making them valuable additions to any toolkit. Whether used in a home workshop or a professional setting, these tools are built to deliver exceptional performance and versatility.