7.Retighten Lock Knob by turning it all the way clockwise.

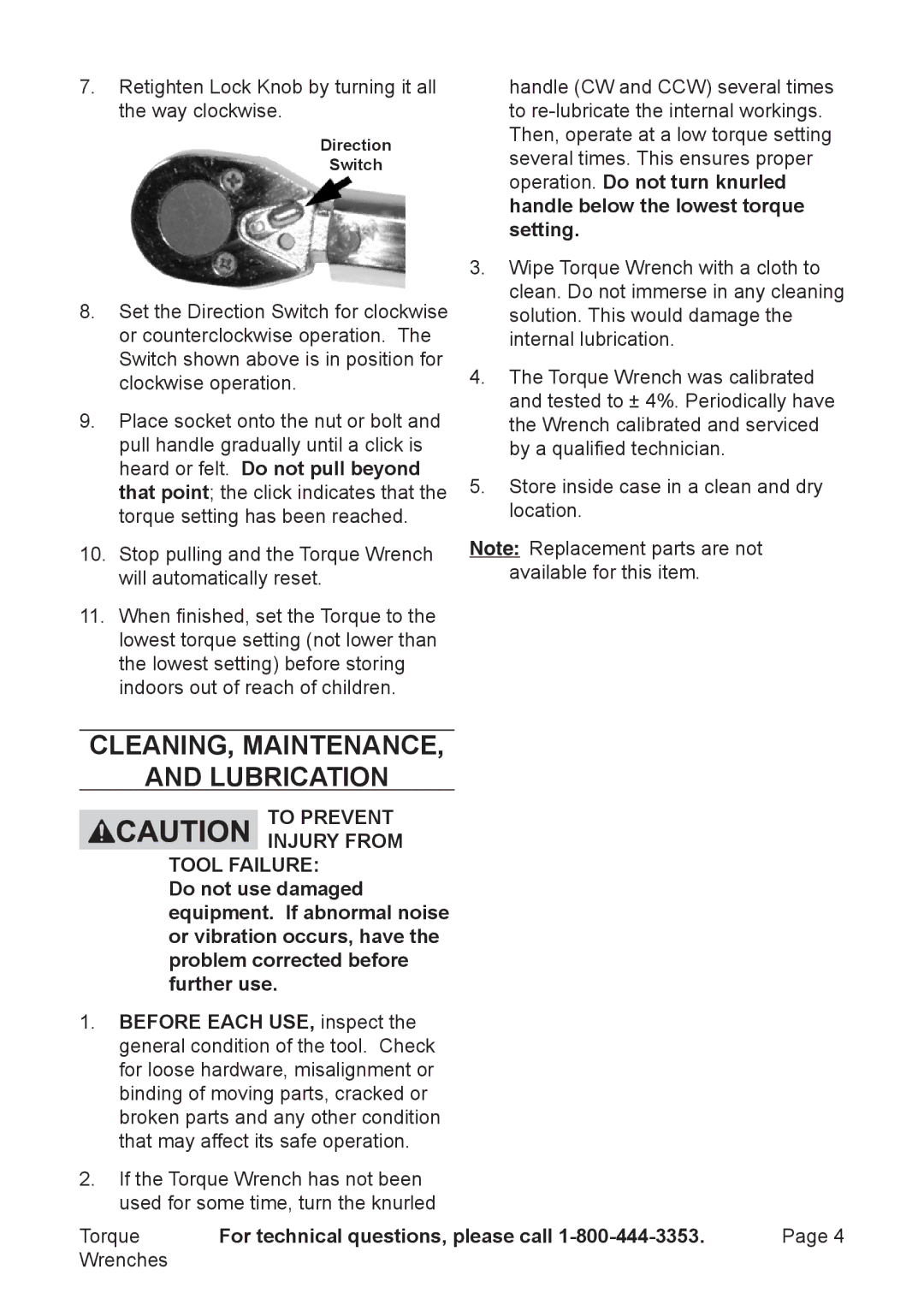

Direction

Switch

8.Set the Direction Switch for clockwise or counterclockwise operation. The Switch shown above is in position for clockwise operation.

9.Place socket onto the nut or bolt and pull handle gradually until a click is heard or felt. Do not pull beyond that point; the click indicates that the torque setting has been reached.

10.Stop pulling and the Torque Wrench will automatically reset.

11.When finished, set the Torque to the lowest torque setting (not lower than the lowest setting) before storing indoors out of reach of children.

Cleaning, Maintenance,

and Lubrication

To prevent injury from

tool failure:

Do not use damaged equipment. If abnormal noise or vibration occurs, have the problem corrected before further use.

1.BEFORE EACH USE, inspect the general condition of the tool. Check for loose hardware, misalignment or binding of moving parts, cracked or broken parts and any other condition that may affect its safe operation.

2.If the Torque Wrench has not been used for some time, turn the knurled

handle (CW and CCW) several times to

3.Wipe Torque Wrench with a cloth to clean. Do not immerse in any cleaning solution. This would damage the internal lubrication.

4.The Torque Wrench was calibrated and tested to ± 4%. Periodically have the Wrench calibrated and serviced by a qualified technician.

5.Store inside case in a clean and dry location.

Note: Replacement parts are not available for this item.

Torque | For technical questions, please call | Page 4 |

Wrenches |

|

|