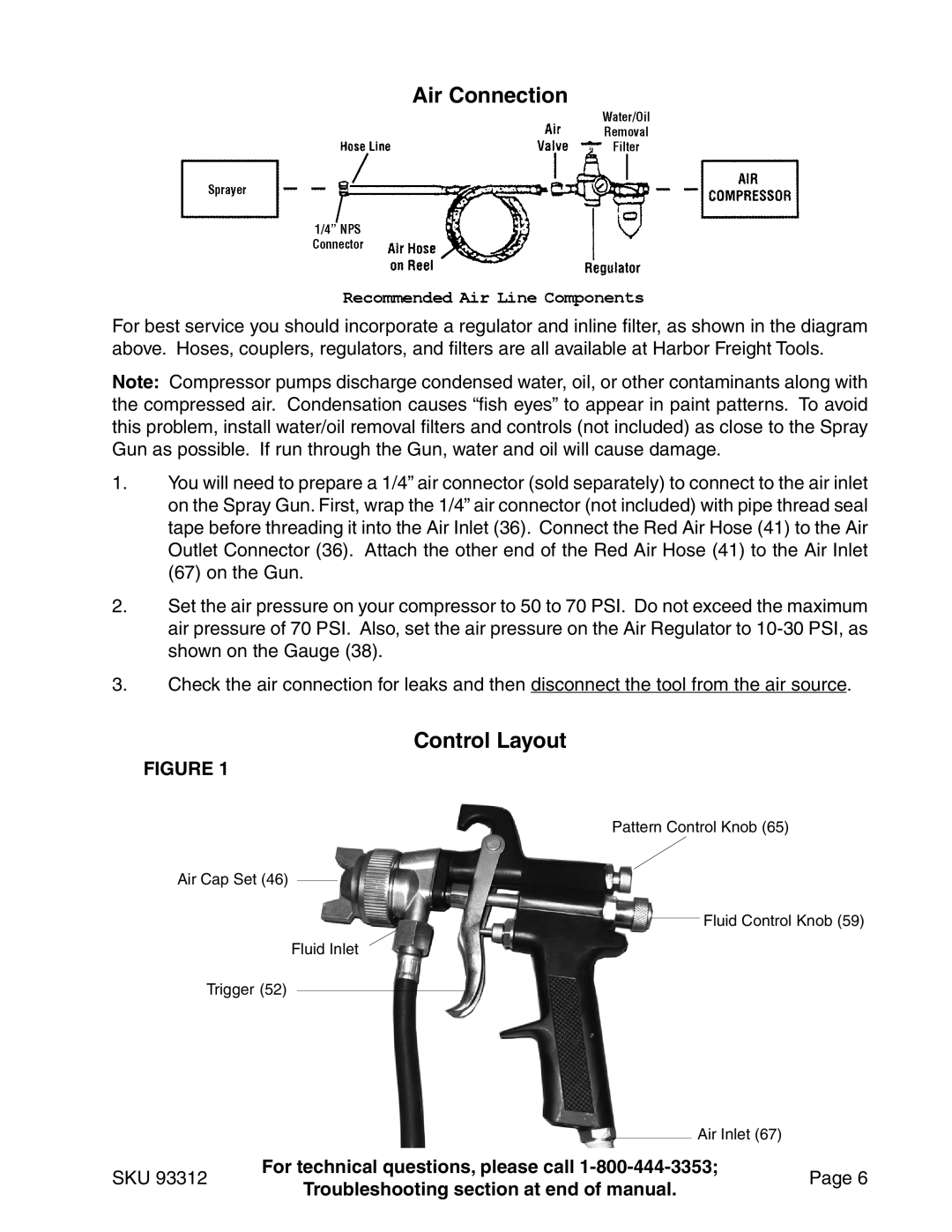

Air Connection

For best service you should incorporate a regulator and inline filter, as shown in the diagram above. Hoses, couplers, regulators, and filters are all available at Harbor Freight Tools.

Note: Compressor pumps discharge condensed water, oil, or other contaminants along with the compressed air. Condensation causes “fish eyes” to appear in paint patterns. To avoid this problem, install water/oil removal filters and controls (not included) as close to the Spray Gun as possible. If run through the Gun, water and oil will cause damage.

1.You will need to prepare a 1/4” air connector (sold separately) to connect to the air inlet on the Spray Gun. First, wrap the 1/4” air connector (not included) with pipe thread seal tape before threading it into the Air Inlet (36). Connect the Red Air Hose (41) to the Air Outlet Connector (36). Attach the other end of the Red Air Hose (41) to the Air Inlet (67) on the Gun.

2.Set the air pressure on your compressor to 50 to 70 PSI. Do not exceed the maximum air pressure of 70 PSI. Also, set the air pressure on the Air Regulator to

3.Check the air connection for leaks and then disconnect the tool from the air source.

Control Layout

FIGURE 1

Pattern Control Knob (65)

Air Cap Set (46)

Fluid Control Knob (59)

Fluid Inlet

Trigger (52)

Air Inlet (67)

SKU 93312 | For technical questions, please call | Page 6 | |

Troubleshooting section at end of manual. | |||

|

|