ASSEMBLY AND OPERATING INSTRUCTIONS

NOTE: For additional information regarding the parts listed in the following pages, refer to the Assembly Diagram on page 14.

1.If necessary, have a certified electrician install (within six feet of where the Sump Pump will be located) a 115 volt, grounded, electrical outlet that is dedicated only to the Pump. Any outlet must be above the water line.

1.![]()

![]() WARNING! Always make sure the Sump Pump is unplugged from its electrical outlet prior to assembling the unit, unclogging the unit, or making any adjustments to the unit.

WARNING! Always make sure the Sump Pump is unplugged from its electrical outlet prior to assembling the unit, unclogging the unit, or making any adjustments to the unit.

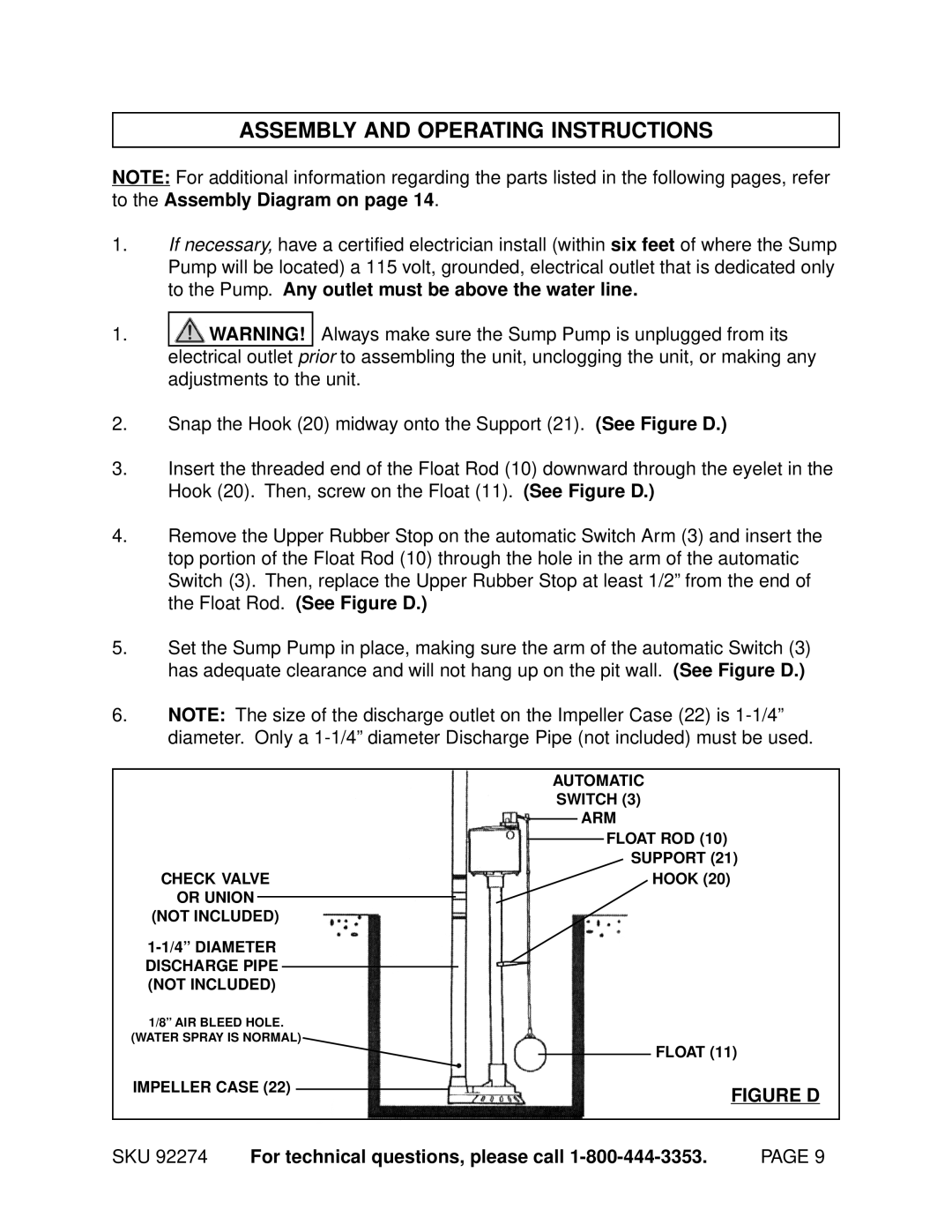

2.Snap the Hook (20) midway onto the Support (21). (See Figure D.)

3.Insert the threaded end of the Float Rod (10) downward through the eyelet in the Hook (20). Then, screw on the Float (11). (See Figure D.)

4.Remove the Upper Rubber Stop on the automatic Switch Arm (3) and insert the top portion of the Float Rod (10) through the hole in the arm of the automatic Switch (3). Then, replace the Upper Rubber Stop at least 1/2” from the end of the Float Rod. (See Figure D.)

5.Set the Sump Pump in place, making sure the arm of the automatic Switch (3) has adequate clearance and will not hang up on the pit wall. (See Figure D.)

6.NOTE: The size of the discharge outlet on the Impeller Case (22) is

AUTOMATIC

SWITCH (3)

ARM

FLOAT ROD (10) SUPPORT (21)

CHECK VALVEHOOK (20) OR UNION

(NOT INCLUDED)

1/8” AIR BLEED HOLE.

(WATER SPRAY IS NORMAL)

IMPELLER CASE (22) |

| FLOAT (11) |

| ||

| FIGURE D | |

|

|

SKU 92274 | For technical questions, please call | PAGE 9 |