Assembly and Operation Instructions (continued)

Note: Performance of the compressor (if powered by line voltage) may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

1.You will need to prepare a 1/4” air connector (sold separately) to connect to the Air Inlet (13) on the Air

Note: If you are not using an automatic oiler system, before operation add a few drops of Pneumatic Tool Oil to the airline connection. Add a few more drops after each hour of continual use.

2.Set the air pressure on your compressor to 90 PSI. Do not exceed the recommended air pressure of 90 PSI.

3.Check the air connection for leaks.

4.Disconnect the air hose until instructed to reconnect.

5.After disconnecting the air supply, squeeze the Trigger Lever (14) to make sure no air remains in the unit.

Assembly:

The only assembly required is the mounting of the Cutting Wheel (29).

Warning: the

(14) to make sure no air remains in the unit.

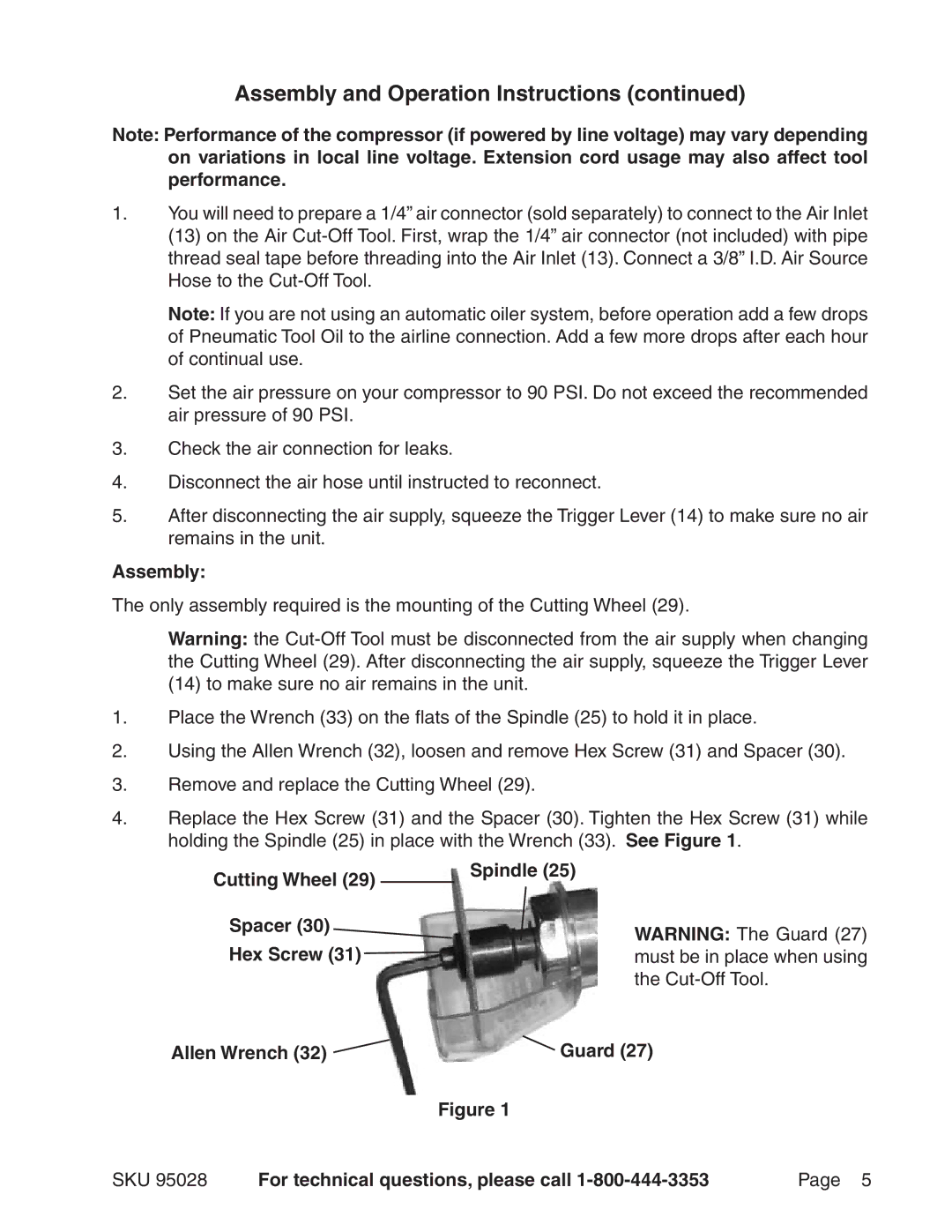

1.Place the Wrench (33) on the flats of the Spindle (25) to hold it in place.

2.Using the Allen Wrench (32), loosen and remove Hex Screw (31) and Spacer (30).

3.Remove and replace the Cutting Wheel (29).

4.Replace the Hex Screw (31) and the Spacer (30). Tighten the Hex Screw (31) while holding the Spindle (25) in place with the Wrench (33). See Figure 1.

Cutting Wheel (29) |

| Spindle (25) |

|

|

Spacer (30)

Hex Screw (31)

WARNING: The Guard (27) must be in place when using the

Allen Wrench (32) | Guard (27) |

Figure 1

SKU 95028 | For technical questions, please call | Page |