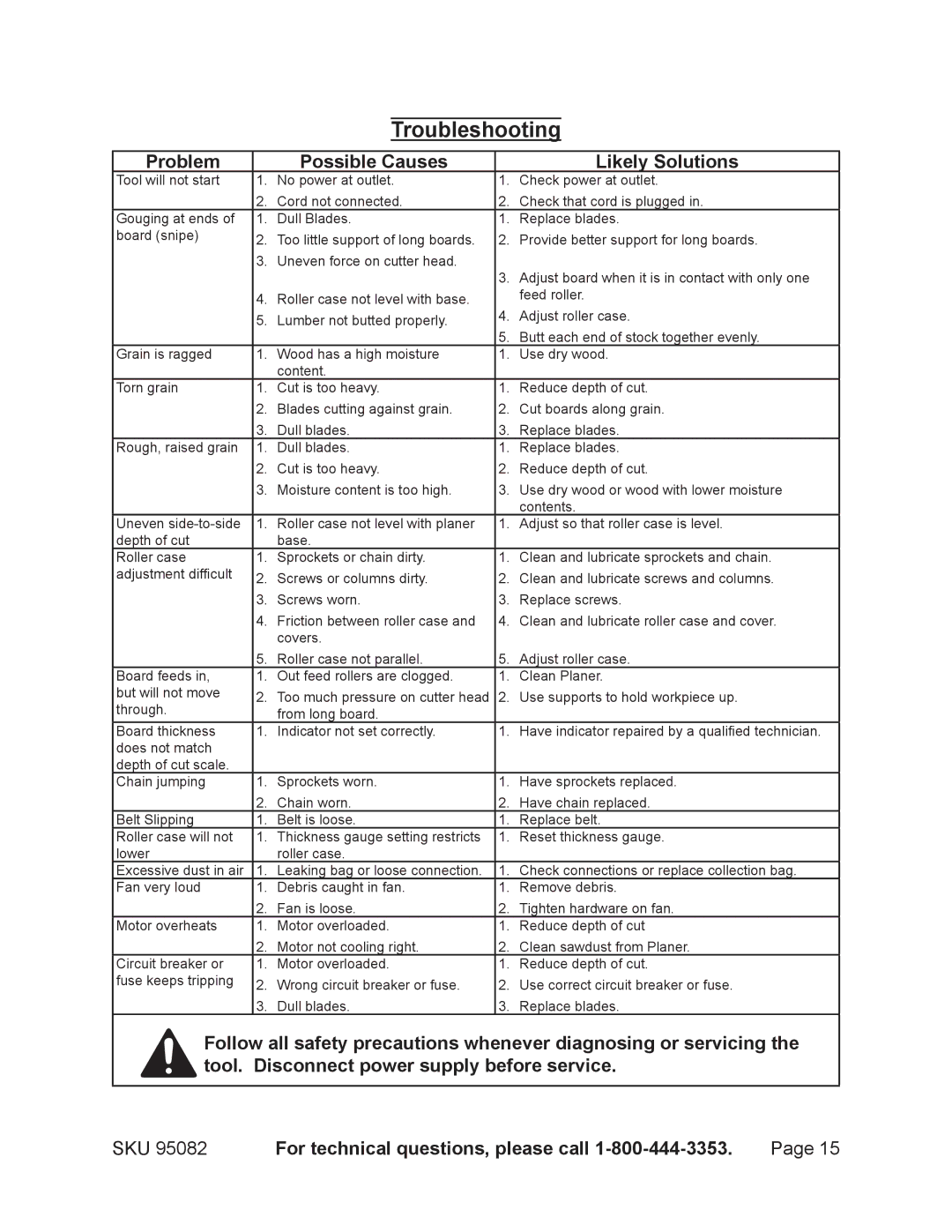

Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

Tool will not start | 1. | No power at outlet. | 1. | Check power at outlet. |

| 2. | Cord not connected. | 2. | Check that cord is plugged in. |

Gouging at ends of | 1. | Dull Blades. | 1. | Replace blades. |

board (snipe) | 2. | Too little support of long boards. | 2. | Provide better support for long boards. |

| 3. | Uneven force on cutter head. | 3. | Adjust board when it is in contact with only one |

|

|

| ||

| 4. | Roller case not level with base. |

| feed roller. |

| 5. | Lumber not butted properly. | 4. | Adjust roller case. |

|

|

| 5. | Butt each end of stock together evenly. |

Grain is ragged | 1. | Wood has a high moisture | 1. | Use dry wood. |

|

| content. |

|

|

Torn grain | 1. | Cut is too heavy. | 1. | Reduce depth of cut. |

| 2. | Blades cutting against grain. | 2. | Cut boards along grain. |

| 3. | Dull blades. | 3. | Replace blades. |

Rough, raised grain | 1. | Dull blades. | 1. | Replace blades. |

| 2. | Cut is too heavy. | 2. | Reduce depth of cut. |

| 3. | Moisture content is too high. | 3. | Use dry wood or wood with lower moisture |

|

|

|

| contents. |

Uneven | 1. | Roller case not level with planer | 1. | Adjust so that roller case is level. |

depth of cut |

| base. |

|

|

Roller case | 1. | Sprockets or chain dirty. | 1. | Clean and lubricate sprockets and chain. |

adjustment difficult | 2. | Screws or columns dirty. | 2. | Clean and lubricate screws and columns. |

| 3. | Screws worn. | 3. | Replace screws. |

| 4. | Friction between roller case and | 4. | Clean and lubricate roller case and cover. |

|

| covers. |

|

|

| 5. | Roller case not parallel. | 5. | Adjust roller case. |

Board feeds in, | 1. | Out feed rollers are clogged. | 1. | Clean Planer. |

but will not move | 2. | Too much pressure on cutter head | 2. | Use supports to hold workpiece up. |

through. |

| from long board. |

|

|

Board thickness | 1. | Indicator not set correctly. | 1. | Have indicator repaired by a qualified technician. |

does not match |

|

|

|

|

depth of cut scale. |

|

|

|

|

Chain jumping | 1. | Sprockets worn. | 1. | Have sprockets replaced. |

| 2. | Chain worn. | 2. | Have chain replaced. |

Belt Slipping | 1. | Belt is loose. | 1. | Replace belt. |

Roller case will not | 1. | Thickness gauge setting restricts | 1. | Reset thickness gauge. |

lower |

| roller case. |

|

|

Excessive dust in air | 1. | Leaking bag or loose connection. | 1. | Check connections or replace collection bag. |

Fan very loud | 1. | Debris caught in fan. | 1. | Remove debris. |

| 2. | Fan is loose. | 2. | Tighten hardware on fan. |

Motor overheats | 1. | Motor overloaded. | 1. | Reduce depth of cut |

| 2. | Motor not cooling right. | 2. | Clean sawdust from Planer. |

Circuit breaker or | 1. | Motor overloaded. | 1. | Reduce depth of cut. |

fuse keeps tripping | 2. | Wrong circuit breaker or fuse. | 2. | Use correct circuit breaker or fuse. |

| 3. | Dull blades. | 3. | Replace blades. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service.

SKU 95082 | For technical questions, please call | Page 15 |