Anytime any maintenance or repairs are done, FIRST:

1.Disconnect the Nailer/Stapler from the air hose.

2.Empty Magazine A (61) completely.

3.Attempt to fire the Nailer/Stapler into a piece of scrap wood to ensure that it is disconnected and is incapable of firing any staples.

4.Always leave Magazine A (61) open during maintenance. The Magazine is spring- loaded and may cause parts or a fastener to fly out of the Nailer/Stapler.

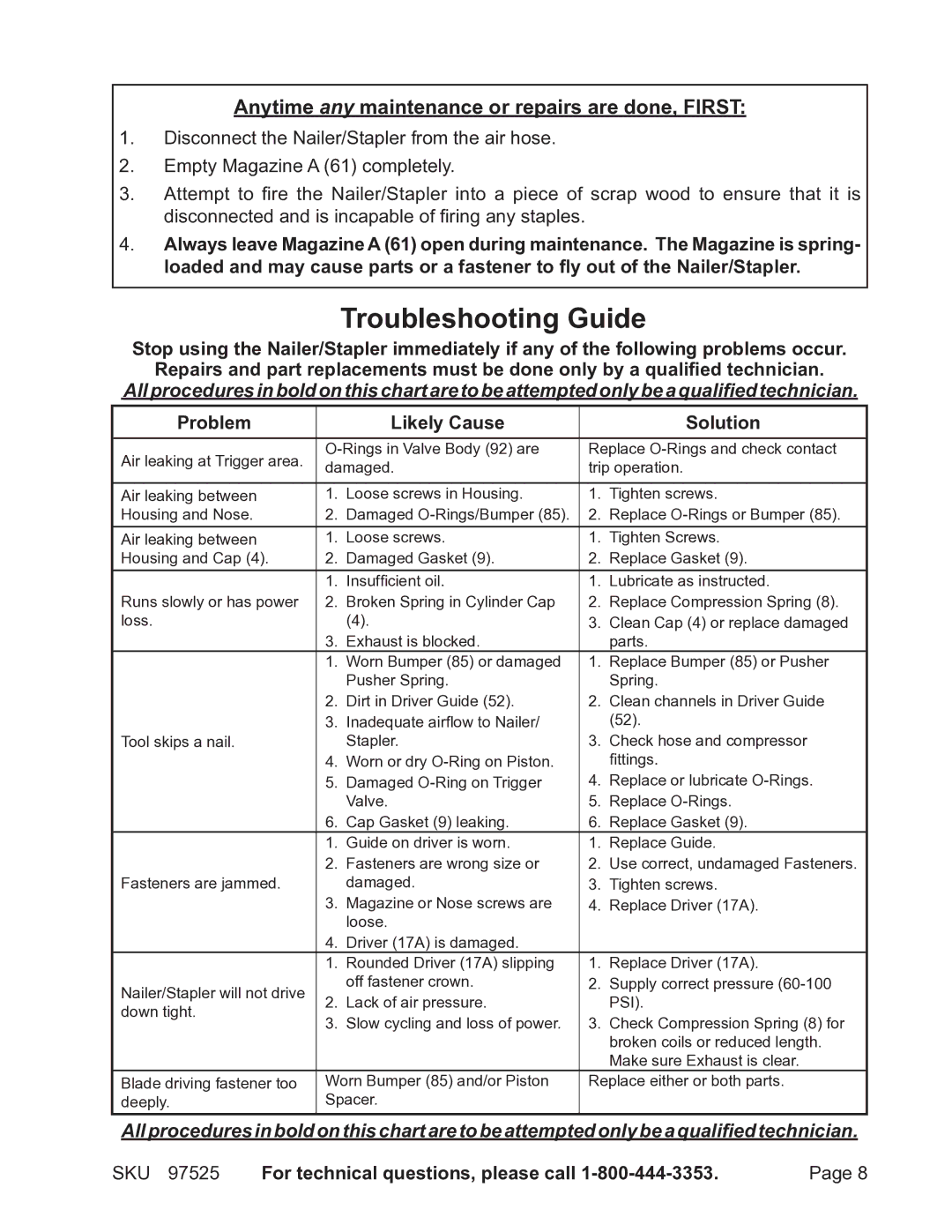

Troubleshooting Guide

Stop using the Nailer/Stapler immediately if any of the following problems occur.

Repairs and part replacements must be done only by a qualified technician.

All procedures in bold on this chart are to be attempted only be a qualified technician.

Problem |

|

| Likely Cause |

| Solution |

|

Air leaking at Trigger area. | Replace | |||||

damaged. | trip operation. |

| ||||

|

|

| ||||

|

|

|

|

|

| |

Air leaking between |

| 1. Loose screws in Housing. | 1. | Tighten screws. |

| |

Housing and Nose. |

| 2. Damaged | 2. | Replace | ||

Air leaking between |

| 1. Loose screws. | 1. | Tighten Screws. |

| |

Housing and Cap (4). | 2. Damaged Gasket (9). | 2. | Replace Gasket (9). |

| ||

|

| 1. | Insufficient oil. | 1. | Lubricate as instructed. |

|

Runs slowly or has power | 2. Broken Spring in Cylinder Cap | 2. | Replace Compression Spring (8). | |||

loss. |

|

| (4). | 3. | Clean Cap (4) or replace damaged | |

|

| 3. | Exhaust is blocked. |

| parts. |

|

|

| 1. | Worn Bumper (85) or damaged | 1. | Replace Bumper (85) or Pusher | |

|

|

| Pusher Spring. |

| Spring. |

|

|

| 2. | Dirt in Driver Guide (52). | 2. | Clean channels in Driver Guide | |

|

| 3. | Inadequate airflow to Nailer/ |

| (52). |

|

Tool skips a nail. |

|

| Stapler. | 3. | Check hose and compressor |

|

|

| 4. | Worn or dry |

| fittings. |

|

|

| 5. | Damaged | 4. | Replace or lubricate | |

|

|

| Valve. | 5. | Replace |

|

|

| 6. | Cap Gasket (9) leaking. | 6. | Replace Gasket (9). |

|

|

| 1. | Guide on driver is worn. | 1. | Replace Guide. |

|

|

| 2. | Fasteners are wrong size or | 2. | Use correct, undamaged Fasteners. | |

Fasteners are jammed. |

| damaged. | 3. | Tighten screws. |

| |

|

| 3. | Magazine or Nose screws are | 4. | Replace Driver (17A). |

|

|

|

| loose. |

|

|

|

|

| 4. | Driver (17A) is damaged. |

|

|

|

|

| 1. | Rounded Driver (17A) slipping | 1. | Replace Driver (17A). |

|

Nailer/Stapler will not drive |

| off fastener crown. | 2. | Supply correct pressure | ||

2. | Lack of air pressure. |

| PSI). |

| ||

down tight. |

|

|

| |||

| 3. | Slow cycling and loss of power. | 3. | Check Compression Spring (8) for | ||

|

| |||||

|

|

|

|

| broken coils or reduced length. | |

|

|

|

|

| Make sure Exhaust is clear. |

|

Blade driving fastener too | Worn Bumper (85) and/or Piston | Replace either or both parts. |

| |||

deeply. |

| Spacer. |

|

|

| |

All procedures in bold on this chart are to be attempted only be a qualified technician. | ||||||

SKU 97525 | For technical questions, please call | Page 8 | ||||