Rigging

Rigging holes are provided on all models. Caution should be exercised when moving these units. To prevent damage to the unit housing during rigging, cables or chains used must be held apart by spacer bars. The mounting platform or base should be level and located so as to permit free access of supply air. The unit weather hood may be removed for the rigging process. The condensing unit cover (wrapper) should be left in place.

Access Requirements

Provide adequate space at the compressor end of the unit for servicing. Provide two (2) feet of space above unit for service.

Mounting

The system requires an opening in the ceiling to the dimensions stated on page 3. Mounting rails are located at both ends of the chassis. Mounting rails may be used to attach unit to ceiling.

Operating Instructions

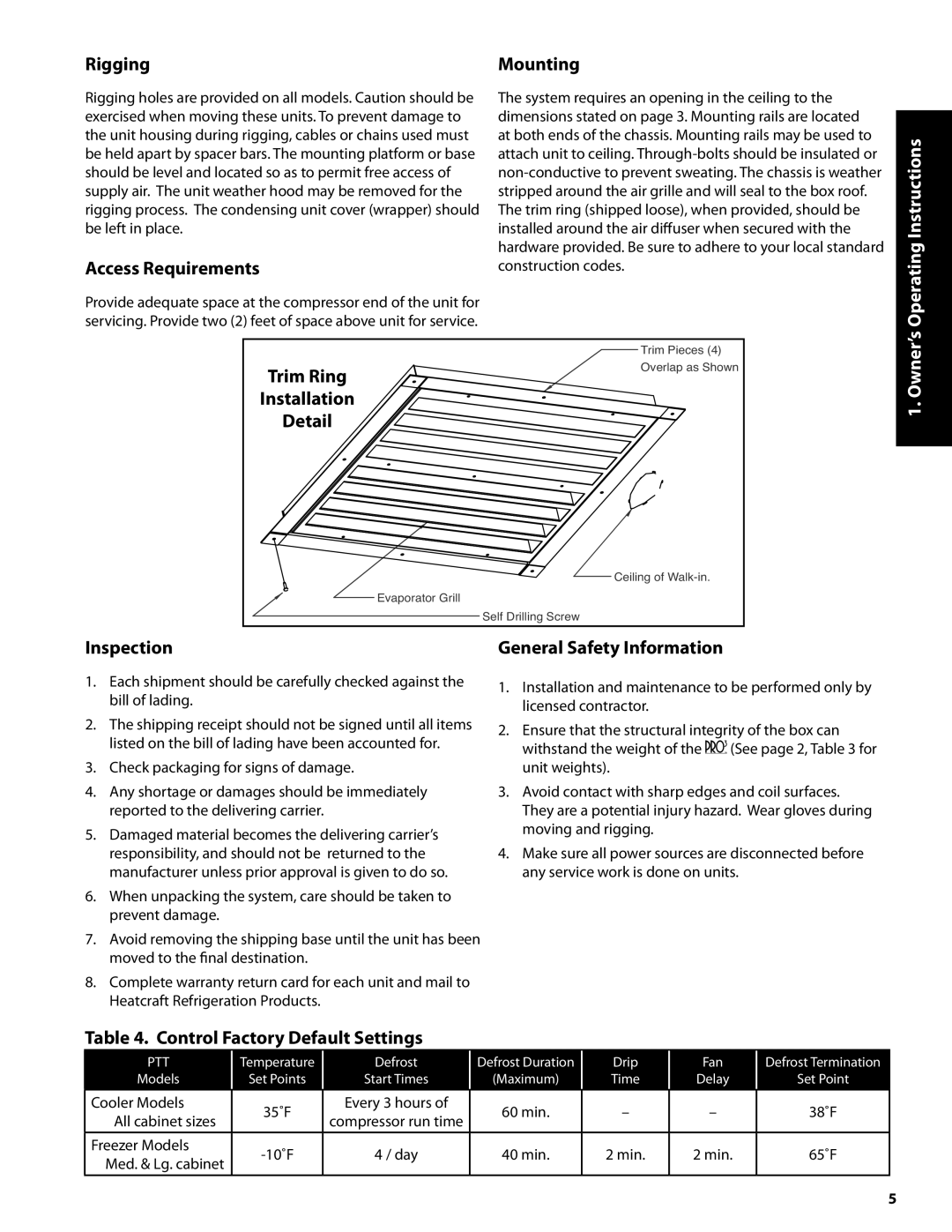

| Trim Pieces (4) |

Trim Ring | Overlap as Shown |

| |

Installation |

|

Detail |

|

| Ceiling of |

| Evaporator Grill |

| Self Drilling Screw |

1. Owner’s

Inspection

1.Each shipment should be carefully checked against the bill of lading.

2.The shipping receipt should not be signed until all items listed on the bill of lading have been accounted for.

3.Check packaging for signs of damage.

4.Any shortage or damages should be immediately reported to the delivering carrier.

5.Damaged material becomes the delivering carrier’s responsibility, and should not be returned to the manufacturer unless prior approval is given to do so.

6.When unpacking the system, care should be taken to prevent damage.

7.Avoid removing the shipping base until the unit has been moved to the final destination.

8.Complete warranty return card for each unit and mail to Heatcraft Refrigeration Products.

Table 4. Control Factory Default Settings

General Safety Information

1.Installation and maintenance to be performed only by licensed contractor.

2.Ensure that the structural integrity of the box can withstand the weight of the ![]()

![]() (See page 2, Table 3 for unit weights).

(See page 2, Table 3 for unit weights).

3.Avoid contact with sharp edges and coil surfaces. They are a potential injury hazard. Wear gloves during moving and rigging.

4.Make sure all power sources are disconnected before any service work is done on units.

PTT | Temperature | Defrost | Defrost Duration | Drip | Fan | Defrost Termination | |

Models | Set Points | Start Times | (Maximum) | Time | Delay | Set Point | |

Cooler Models | 35˚F | Every 3 hours of | 60 min. | – | – | 38˚F | |

All cabinet sizes | compressor run time | ||||||

|

|

|

|

| |||

Freezer Models | 4 / day | 40 min. | 2 min. | 2 min. | 65˚F | ||

Med. & Lg. cabinet | |||||||

|

|

|

|

|

|