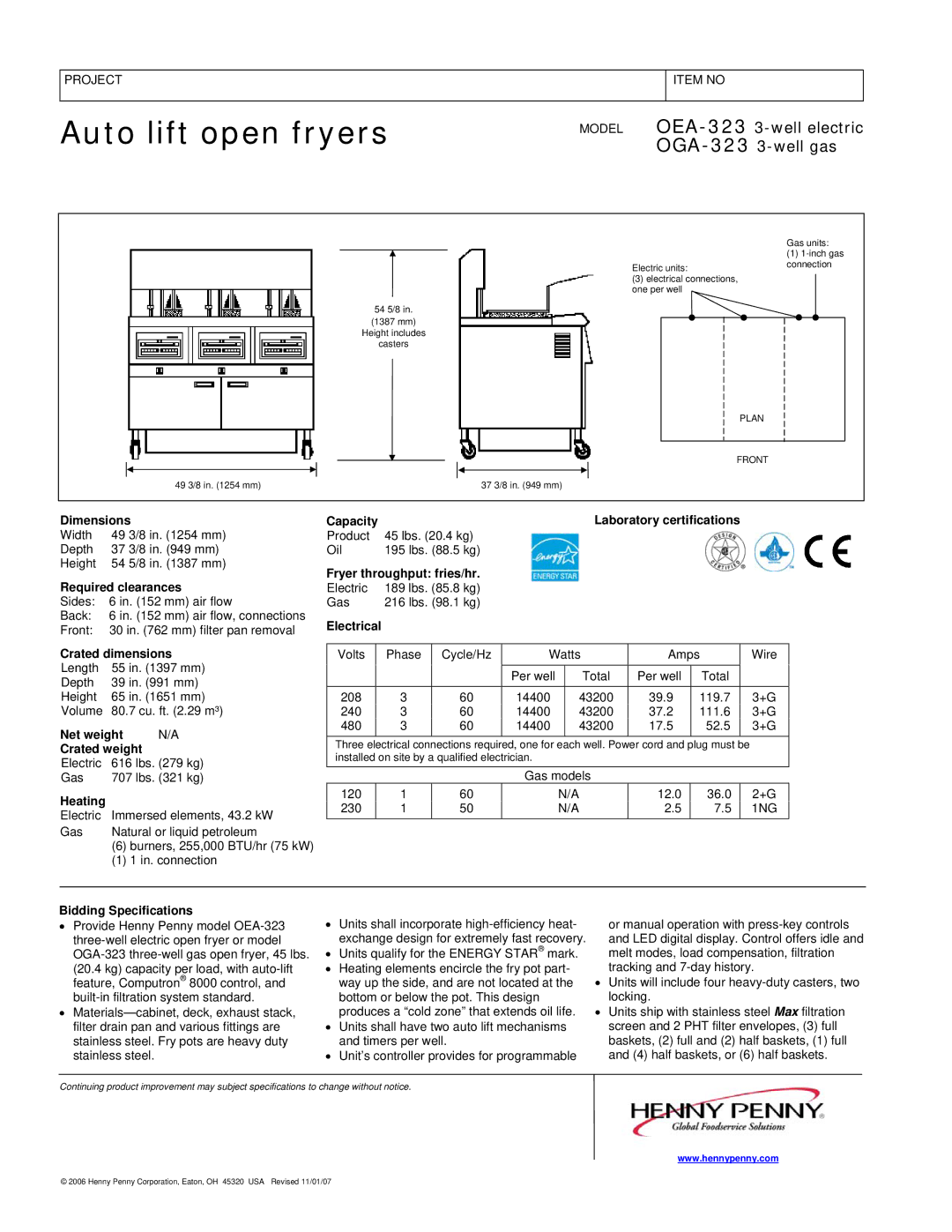

OGA-323, OEA-323 specifications

Henny Penny OEA-323 and OGA-323 are advanced commercial cooking appliances designed to meet the demands of high-volume food service operations. Renowned for their reliability and efficient performance, these models reflect Henny Penny's commitment to innovative cooking technology.The Henny Penny OEA-323 is an electric combi oven that combines the advantages of convection and steam cooking. This unique dual function allows chefs to create a diverse range of dishes, from perfectly baked pastries to succulent roasted meats. Equipped with advanced temperature control, this oven ensures food is cooked evenly and retains moisture, enhancing flavors and textures. The OEA-323 also features a user-friendly digital control panel that aids in programming and monitoring cooking cycles, allowing for precision cooking.

On the other hand, the OGA-323 is a gas-powered version that incorporates similar functionalities but harnesses the power of gas for heating. This model is particularly beneficial for high-volume kitchens seeking rapid warm-up times and high efficiency. The OGA-323 is designed to deliver consistent results while minimizing cooking times, a significant advantage in fast-paced restaurant environments.

Both models are equipped with advanced humidity control systems that help maintain optimal moisture levels during the cooking process, ensuring that food remains succulent and flavorful. The addition of a self-cleaning feature greatly reduces maintenance time, allowing busy kitchen staff to focus on food preparation instead of appliance upkeep.

In terms of construction, Henny Penny ovens are built with stainless steel bodies that offer durability and ease of cleaning. The high-efficiency insulation ensures minimal heat loss, which translates into energy savings and lower utility bills. Furthermore, these ovens are designed to fit seamlessly into standard kitchen layouts, maximizing space without compromising functionality.

Among the other notable characteristics of the OEA-323 and OGA-323 are their compatibility with a wide range of cooking accessories, including racks and trays, allowing chefs to customize their cooking setups based on the specific requirements of their menus. Additionally, both models boast comprehensive safety features to protect operators during use, including automatic shut-off systems and cool-to-the-touch door handles.

In conclusion, the Henny Penny OEA-323 and OGA-323 represent a blend of technology, efficiency, and versatility, making them ideal choices for modern commercial kitchens aiming to elevate their culinary offerings while ensuring operational excellence.